Power supply module test device

A technology of power module and testing equipment, which is applied in the field of power module testing equipment, can solve the problem that the ball power module without pins and solders cannot be detected, and achieve the effect of not damaging the contacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

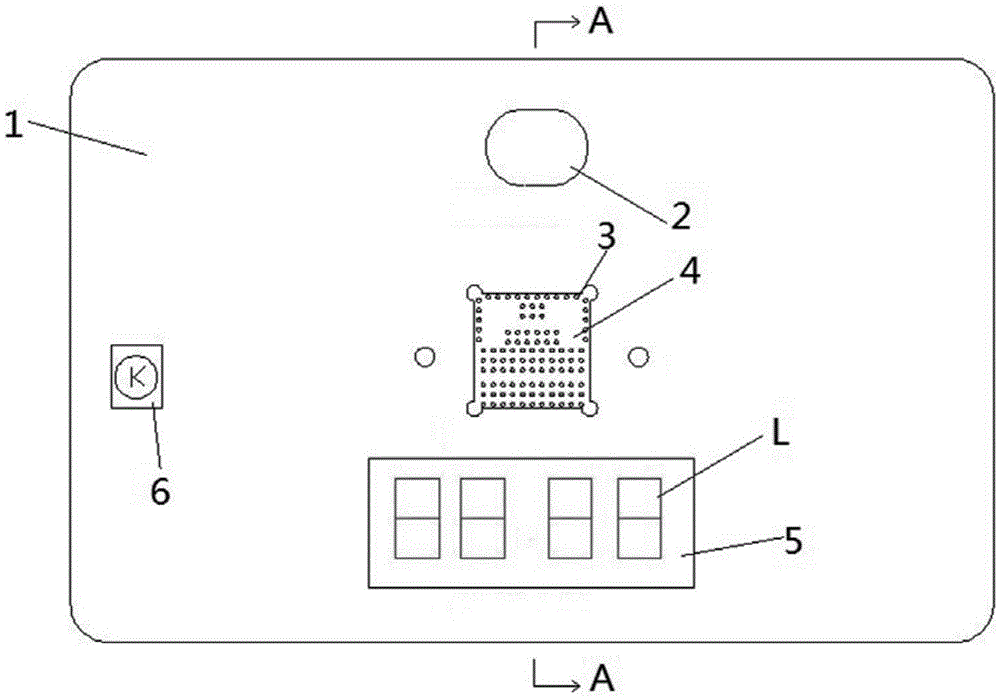

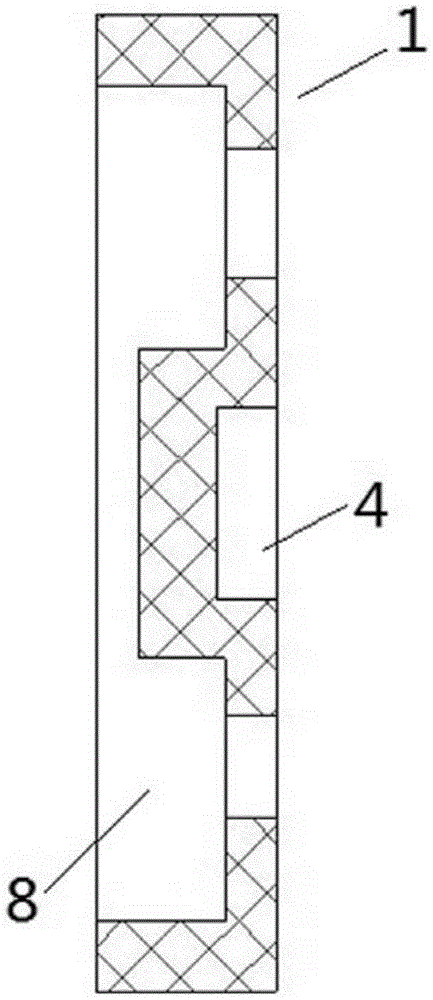

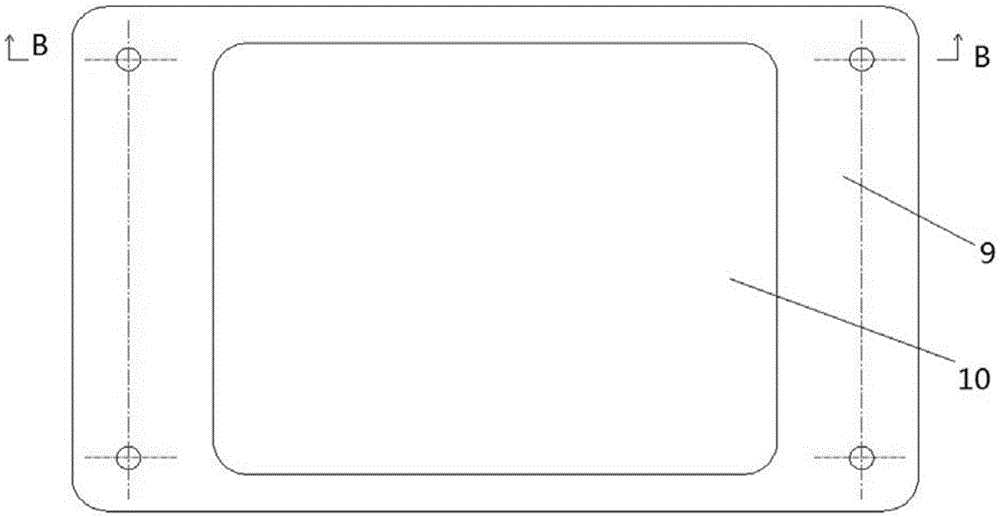

[0021] An embodiment of a power module testing equipment such as Figure 1~5 Shown: include test base, test base comprises upper cover plate 1, lower cover plate 9 and circuit board (not shown in the figure), upper cover plate accommodation cavity 8 is arranged on the lower plate surface of upper cover plate 1, lower cover The upper surface of the plate 9 is provided with a lower cover plate accommodation chamber 10, the upper and lower accommodation chambers form a space for setting the circuit board, the upper and lower cover plates are assembled together by screws, and the circuit board is arranged between the upper and lower cover plates , so that the circuit board can be protected. A test circuit is arranged on the circuit board, and vertically arranged contacts (not shown in the figure) are arranged on the lower cover. The part and the floating contact part are mounted on the installation part through the spring float, and the installation part is connected with the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com