Bus assembly and gas insulated metal-enclosed switchgear using the bus assembly

A technology of closed switchgear and gas-insulated metal, which is applied in the setting of switchgear, switchgear, cooling busbar device, etc., can solve the problems that the temperature rise easily exceeds the national standard requirements and cannot meet the performance requirements of power equipment, and achieves the reduction of temperature rise , speed up heat dissipation, increase the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

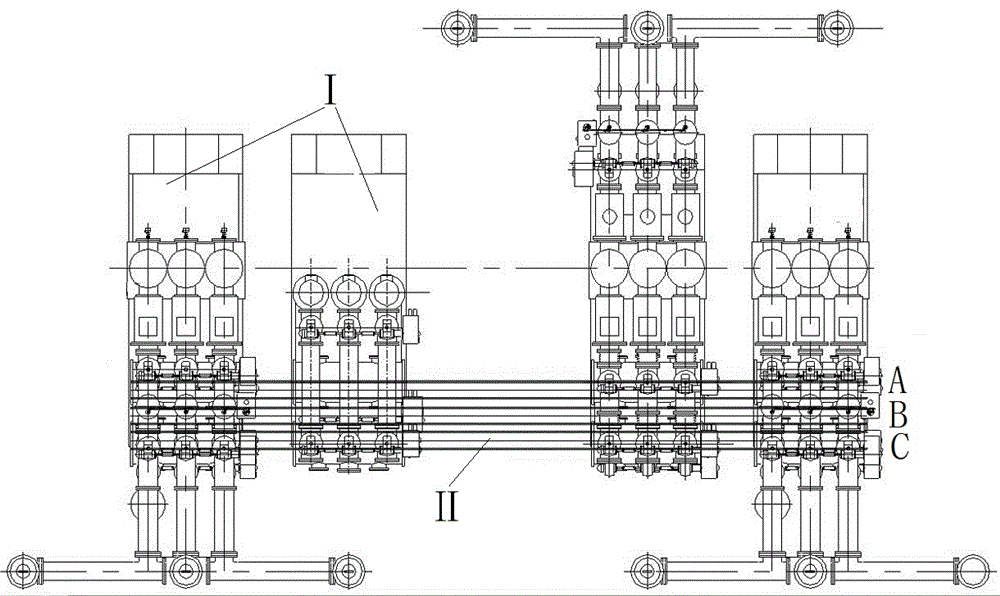

[0023] Examples of gas-insulated metal-enclosed switchgear:

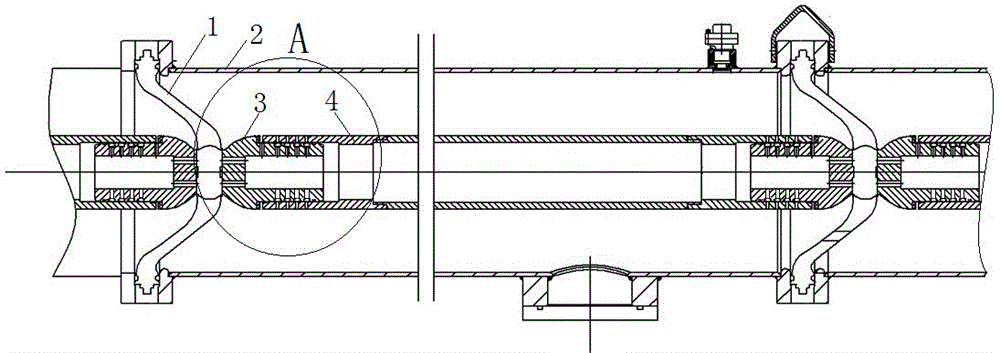

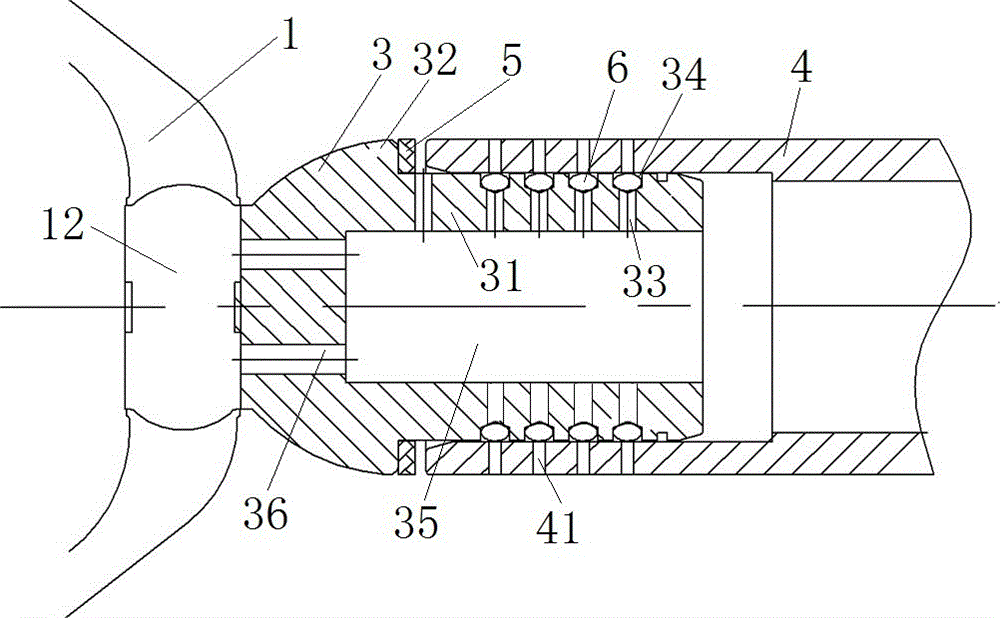

[0024] The structure of gas-insulated metal-enclosed switchgear is as follows: figure 1 As shown, it includes a plurality of bays I, and the multiple bays I are electrically connected through the busbar assembly II to realize the current confluence and distribution between the bays. The busbar assembly II includes A, B, and C three-phase buses. structured as Figure 2~5 As shown, it includes a pot insulator 1 and a shell 2 fixed between two adjacent pot insulators through flange clamping. The pot insulator 1 is located in the shell 2 and includes an insulating body 11 made of epoxy resin. And the central conductor 12 made of aluminum, the electrical connection 3 is fixed on the central conductor 12 by bolts to realize the conductive connection between the central conductor 12 and the electrical connection 3 .

[0025] The electrical connection 3 includes a plug-in section 31 at the front end and a flange 32 protru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com