Fermentation technology of low-salt fermented bean curd

A fermentation process and salt-cured technology, applied in the field of low-salt fermented fermented fermented bean curd, can solve the problems that high-salt fermented fermented fermented fermented fermented bean curd cannot meet customer needs, the taste and appearance cannot be guaranteed, and the probiotic compound starter is too many, so as to achieve small individual differences. , The batch difference is small, and the effect of reducing the browning of the green body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

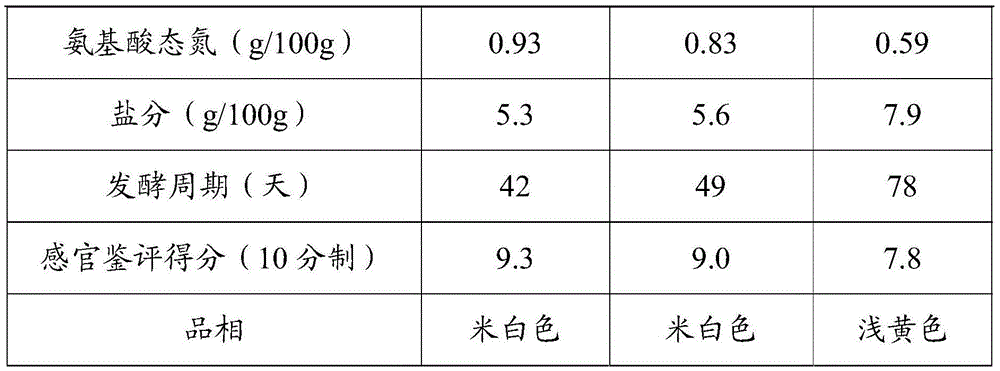

Embodiment 1

[0037] A fermentation process of low-salt fermented bean curd, comprising the following steps:

[0038] 1) Blank making: Soak soybeans, refine them, and filter them, then boil them with steam for 15 minutes, keep the cooked pulp at ≥98°C for 6 minutes, sieve to obtain bean dregs and soy milk, and sieve to obtain bean dregs and soy milk. , making blanks and cutting into pieces to obtain tofu white blanks;

[0039] 2) Inoculation culture: take 60 g of a sterile culture medium with a pH of 4.8-7.2 and place it in an Erlenmeyer flask, inoculate 5 mL of Mucor-Rizopus oryzae mixed spore suspension, and cultivate at 29° C. to obtain a strain liquid; among them, Mucor The number of spores and Rhizopus oryzae spores is about 2:3; the spore suspension is a normal saline solution of spores, and the concentration of spores is 1.0-2.0×10 6 individual / mL; the preparation method of the medium is as follows: add 200g bean dregs, 1g KH in the bran of every 100g 2 PO 4 , 0.5g MgSO 4 ·7H 2 ...

Embodiment 2

[0045]A fermentation process of low-salt fermented bean curd, comprising the following steps:

[0046] 1) Blank making: Soak soybeans, refine them, and filter them, then boil them with steam for 30 minutes, keep the cooked pulp at ≥ 98°C for 6 minutes, sieve to obtain bean dregs and soy milk, and sieve to obtain bean dregs and soy milk. , making blanks and cutting into pieces to obtain tofu white blanks;

[0047] 2) Inoculation culture: take 60g of sterile culture medium with a pH of 4.8-7.2 and place it in a conical flask, inoculate 5mL of Mucor-Rizopus oryzae mixed spore suspension, and cultivate at 28°C to obtain a strain liquid; among them, Mucor The ratio of spores to Rhizopus oryzae spores is about 4:1; the spore suspension is a normal saline solution of spores, and the concentration of spores is 1.0-2.0×10 6 individual / mL; the preparation method of the medium is as follows: add 200g bean dregs, 1g KH in the bran of every 100g 2 PO 4 , 0.5g MgSO 4 ·7H 2 O, after mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com