C3N4 nanocomposite, preparation method and application of C3N4 nanocomposite

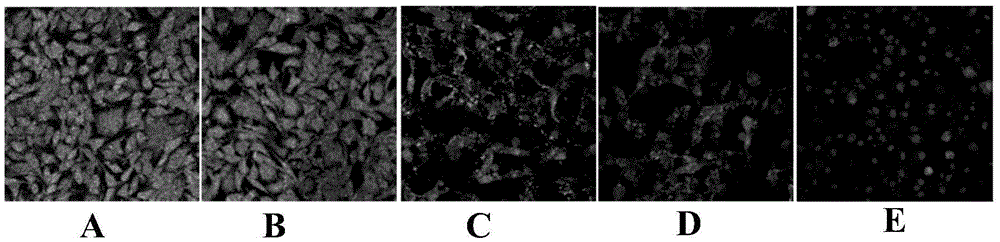

A nanocomposite material, C3N4 technology, applied in the field of nanomedical materials and nanomedical materials for tumor treatment, can solve problems such as limiting the treatment efficiency of photodynamic therapy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a kind of above-mentioned C 3 N 4 The preparation method of nanocomposite material, comprises: the C that loads transition metal element 3 N 4 Two-dimensional nanosheets and photosensitizers were mixed in water and stirred in the dark to obtain C 3 N 4 nanocomposites.

[0036] Wherein, the C of the loaded transition metal element 3 N 4 The two-dimensional nanosheets and the photosensitizer are the same as those described above, and will not be repeated here. The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0037] The C of the loaded transition metal element 3 N 4 The two-dimensional nanosheets were prepared according to the following method: C 3 N 4 Ultrasonic exfoliation of nanomaterials in water to obtain C loaded with transition metal elements 3 N 4 Two-dimensional nanosheets. Wherein, the C of the layered loaded metal element 3 N...

Embodiment 1

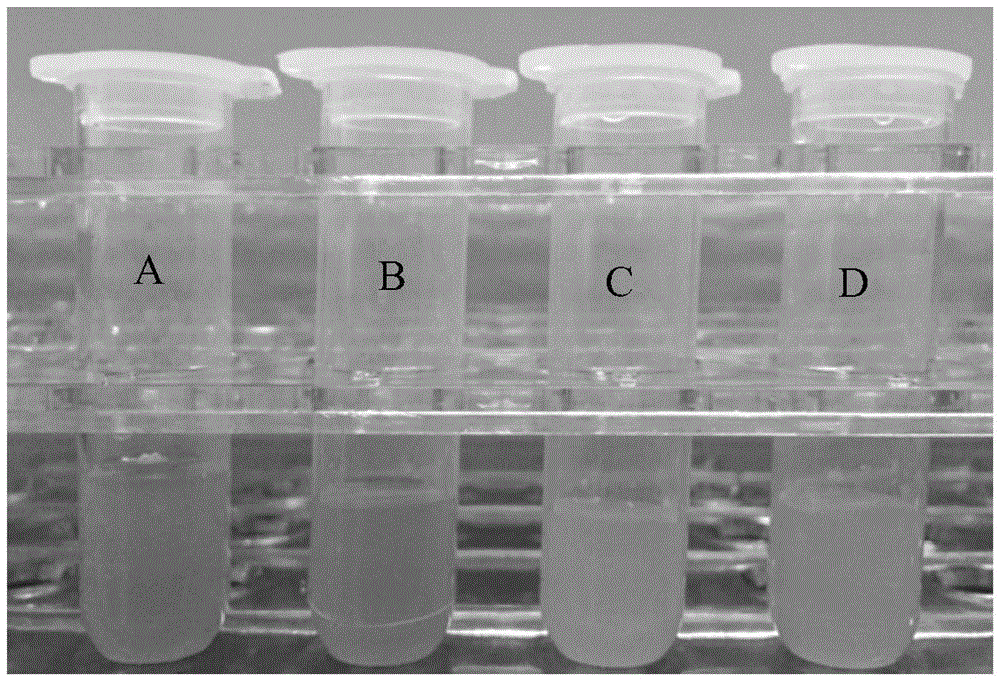

[0049] 1.1 Weigh 10g of dicyandiamide and 1g of ferric chloride dissolved in 50mL of ultrapure water, stir at 80°C until the water is completely evaporated; put the obtained brick red solid powder into a tube furnace, under the protection of nitrogen, The temperature was programmed to 600 °C at a rate of 2.3 °C per minute and maintained at 600 °C for 4 hours, and then cooled naturally to obtain a light brown layered C 3 N 4 -Fe nanomaterials.

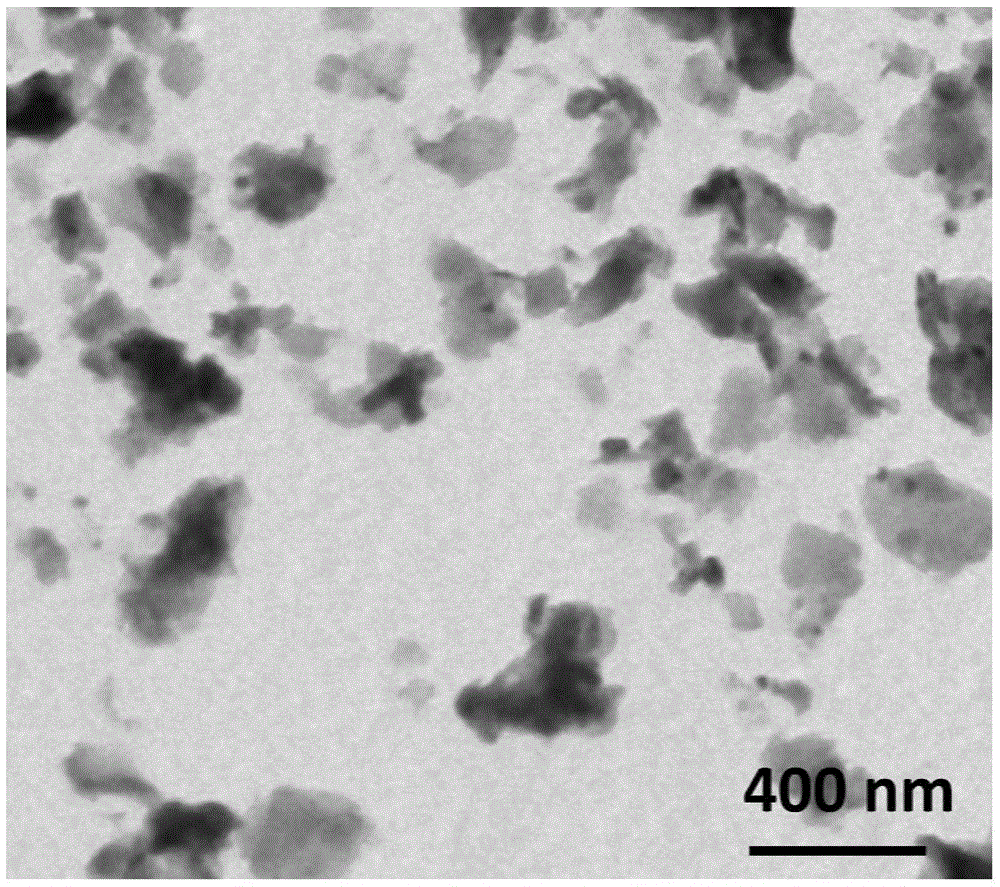

[0050] 1.2 Weigh 100mg of layered C obtained in 1.1 3 N 4 - Fe nanomaterials, dispersed in 100mL ultrapure water, ultrasonically stripped for 16 hours; centrifuge the above mixed solution at a centrifugal force of 5000g for 10 minutes, discard the bottom sediment, continue to centrifuge the supernatant at 10000g for 10 minutes, discard the supernatant , the bottom product obtained is C 3 N 4 -Fe two-dimensional nanosheets.

[0051] 1.3 Weigh the C obtained in 1mg1.2 3 N 4 -Fe two-dimensional nanosheets were dispersed in 10 mL of...

Embodiment 2

[0054] 2.1 Weigh 10g of dicyandiamide and 1g of cobalt chloride dissolved in 50mL of ultrapure water, stir at 80°C until the water is completely evaporated; put the obtained red solid powder into a tube furnace, and under the protection of nitrogen, The temperature was programmed to 600 °C at a rate of 2.3 °C per minute and maintained at 600 °C for 4 hours, and then cooled naturally to obtain a pink layered C 3 N 4 -Co nanomaterials;

[0055] 2.2 Weigh 100 mg of layered C obtained in 2.1 3 N 4 -Co nanomaterials, dispersed in 100mL ultrapure water, ultrasonically stripped for 16 hours; centrifuge the above mixed solution for 10 minutes under a centrifugal force of 5000g, discard the bottom sediment, continue to centrifuge the supernatant at 10000g for 10 minutes, discard the supernatant , the bottom product obtained is C 3 N 4 -Co two-dimensional nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com