a c 3 no 4 Preparation method of nanowire

A C3N4 and nanowire technology, applied in the field of preparation of C3N4 nanowires, can solve problems such as weak oxidation ability, and achieve the effects of short reaction time, improved yield, and ideal spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

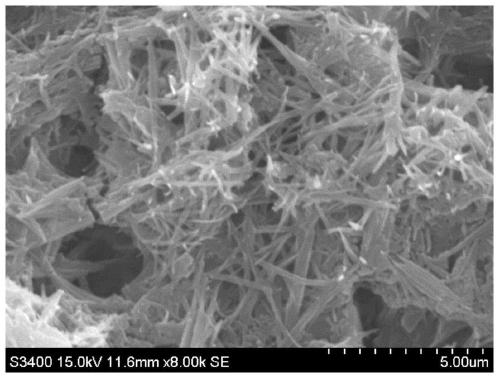

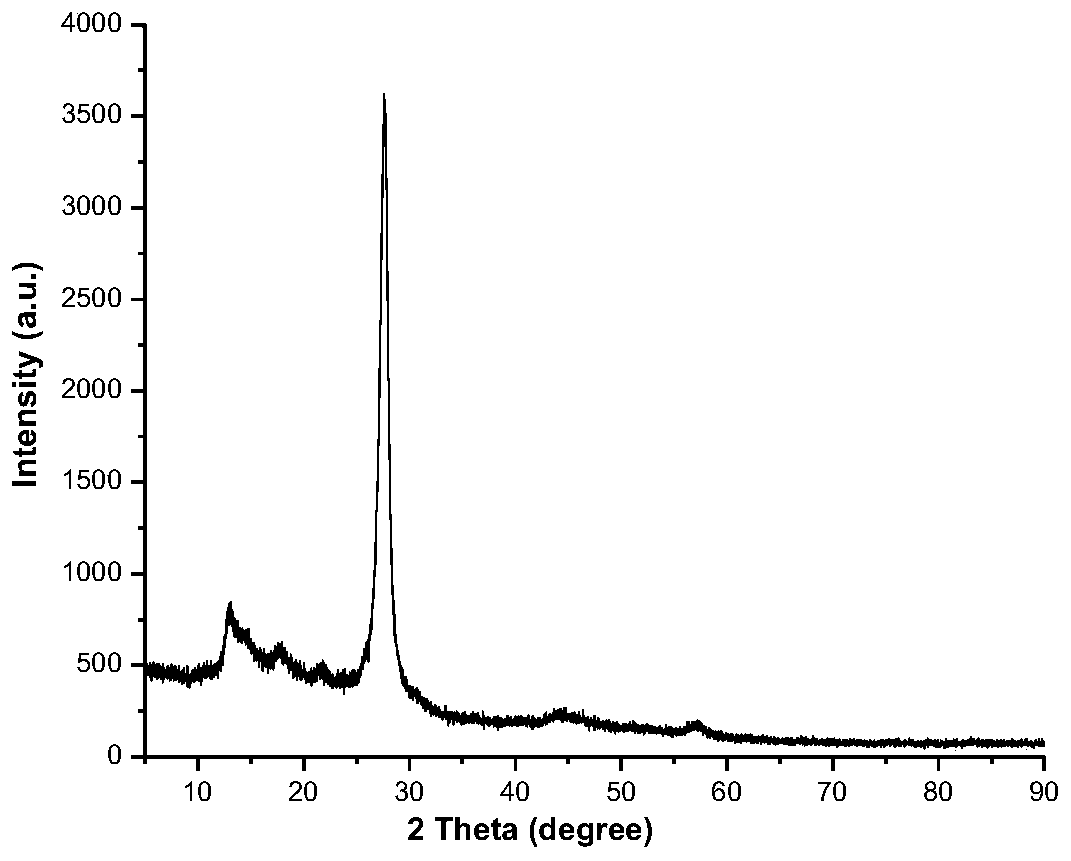

[0017] Grind and mix 5 g of melamine precursor and 1 g of sodium hydroxide in a crucible, place in a muffle furnace and heat up to 500 °C for 2 h at 5 °C / min, add 10 mL of deionized water after cooling down, filter, wash with water, and dry. i.e. get C 3 N 4 Nanowires.

[0018] In order to test the C prepared in this example 3 N 4 The photocatalytic properties of nanowires were tested for photocatalytic degradation of methylene blue: the photocatalytic reaction was carried out in a cylindrical glass reactor, with a 300W xenon lamp as the light source, and the light source was 20cm away from the liquid surface; magnetic stirring was added below the reaction vessel to make The solution is fully mixed to keep the concentration and temperature uniform. Catalyst C 3 N 4 The amount of nanowires was 1g / L, and the initial concentration of methylene blue was 20mg / L. After 1h, the photocatalytic degradation rate of methylene blue reached 84.56%.

Embodiment 2

[0020] Grind and mix 5g of melamine precursor and 5g of potassium hydroxide in a crucible, place it in a muffle furnace and heat up to 520°C at 10°C / min for 2.5h, then add 10mL of deionized water after cooling down, then filter, wash with water, and dry , that is, get C 3 N 4 Nanowires, the photocatalytic degradation rate of methylene blue reached 85.67%.

Embodiment 3

[0022] Mix 5g of melamine precursor and 2g of sodium oxide in a crucible, place it in a muffle furnace and heat up to 500°C at 4°C / min for 2.5h, then add 10mL of deionized water after cooling down, then filter, wash with water, and dry. get C 3 N 4 Nanowires, the photocatalytic degradation rate of methylene blue reached 86.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com