Remotely-controlled liquid dosing machine

A technology of remote control and batching machine, which is applied to mixers, mixers, and mixer accessories with rotating stirring devices, etc., can solve the problems of lower quality of finished products, inconvenient batching, batching precision and accuracy errors, etc., to improve speed and accuracy. Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

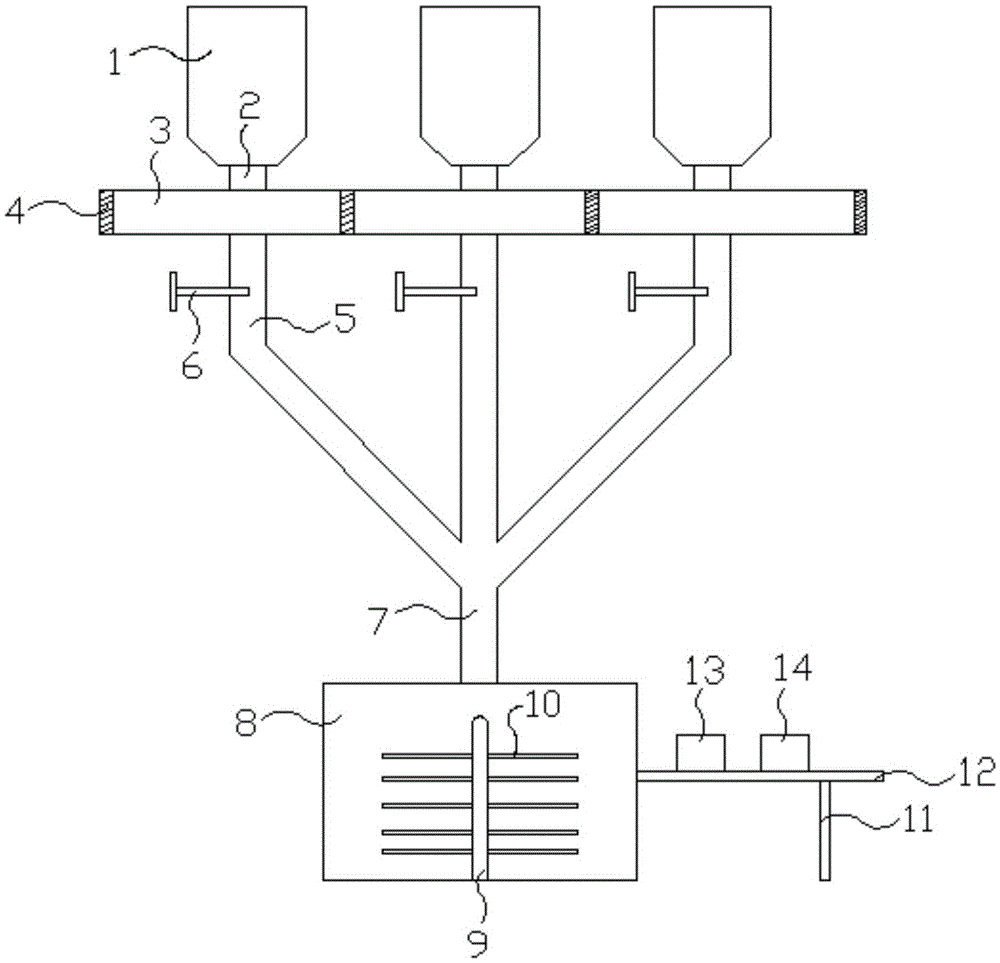

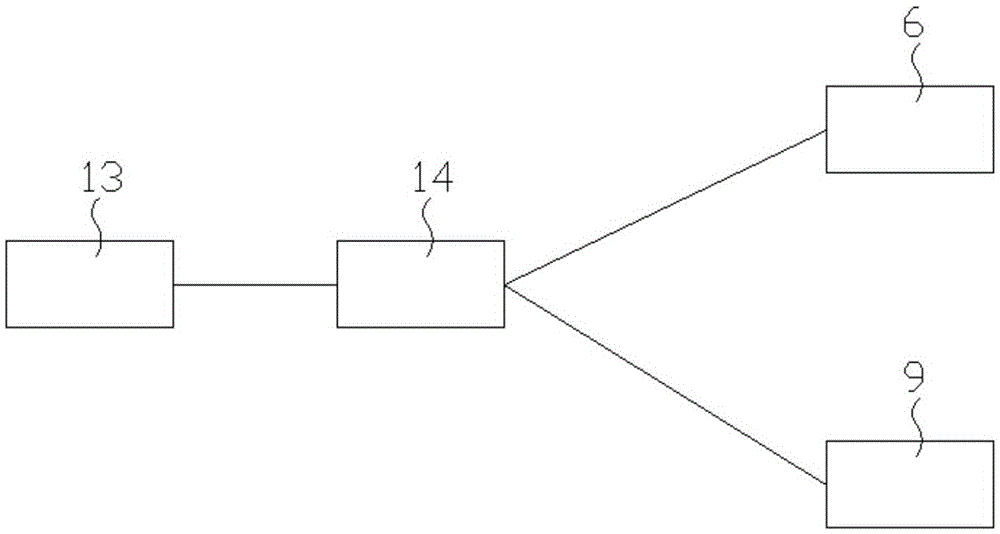

[0017] This embodiment provides a remote-controlled liquid batching machine, such as Figure 1-2 As shown, a number of storage hoppers 1 are included and one end of the storage hopper 1 is provided with a feed pipe 2, and one end of the feed pipe 2 is connected to the feed tank 3 and one side of the feed tank 3 is connected with a feed pipe 5 for feeding A solenoid valve 6 is arranged in the feed pipe 5, the feed pipe 5 is connected to the confluence pipe 7 and one end of the confluence pipe 7 is connected to the stirring tank 8, and a control signal receiver 13 is arranged on one side of the stirring tank 8 and the control signal receiver 13 A controller 14 is provided on one side.

[0018] Further, partitions 4 are arranged between the material storage tanks 3, which can prevent the phenomenon of cross-feeding of the raw materials between the various material storage tanks 3; one side of the mixing box 8 is provided with a support rod 11 and one end is provided with a mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com