Steel belt scraper grinding machine

A scraper and steel belt technology, applied in the direction of grinding bed, grinding machine parts, grinding frame, etc., can solve the problems of high motion precision, low production efficiency, long stroke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

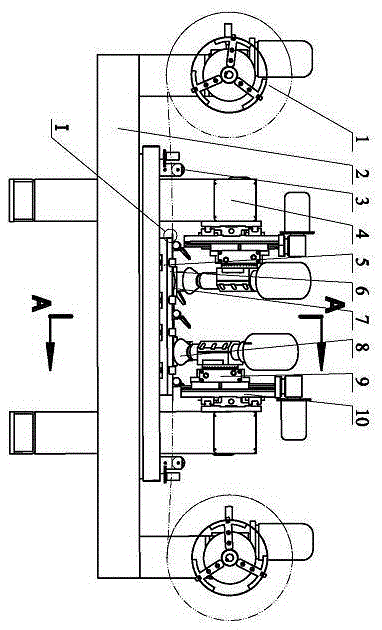

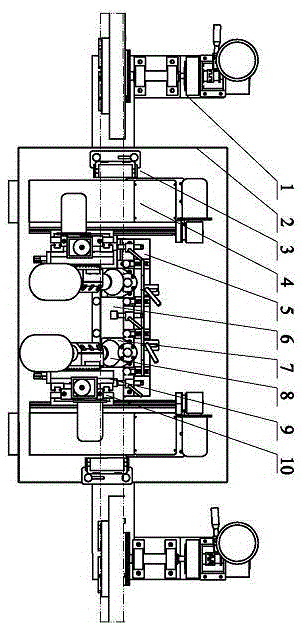

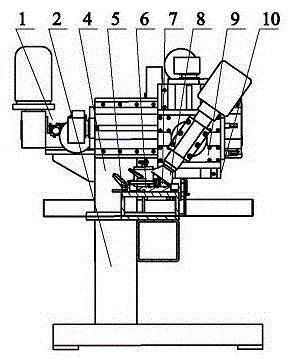

[0036] in figure 1 , figure 2 and image 3 In the steel belt scraper grinder shown, the frame 2 is the basic support member of the entire grinder, and is fixedly connected to the foundation through the feet.

[0037] A base 5 is supported and installed on the frame 2. The base 5 is located in the middle of the upper plane of the frame 2, and a workbench 6 is provided on the base 5, see Figure 8 , There are several anti-friction grooves along the length of the workbench 6, and a pressure plate 7 is provided above the workbench 6, and two pressure plates 7 are provided along the length of the workbench 6, respectively. The lower scraper 11 is installed. See the installation diagram of the lower scraper 11 Figure 5 ;Such as Picture 9 As shown, each pressure plate 7 is installed on the workbench 6 through its respective mandrel 20, and a pressure plate sleeve 19 is movably sleeved on the mandrel 20. The pressure plate 7 is arranged and installed at the lower end of the pressure pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com