Conveyer

A technology of transmission device and transmission device, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc. It can solve the problems that impurities cannot be adsorbed again, inconvenient transportation, machine damage, etc., and it is convenient and effective to move the equipment and fix the base Heat dissipation and transportation, avoiding the effect of adsorption saturation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

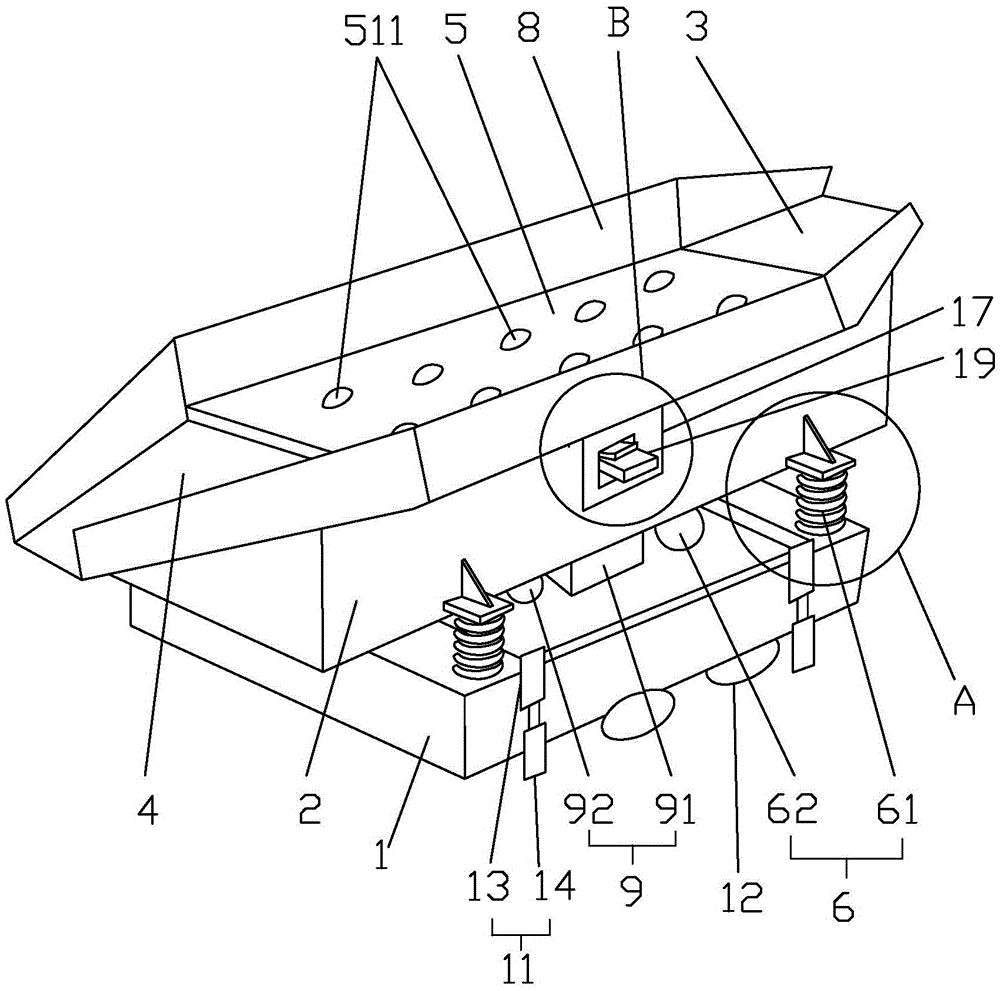

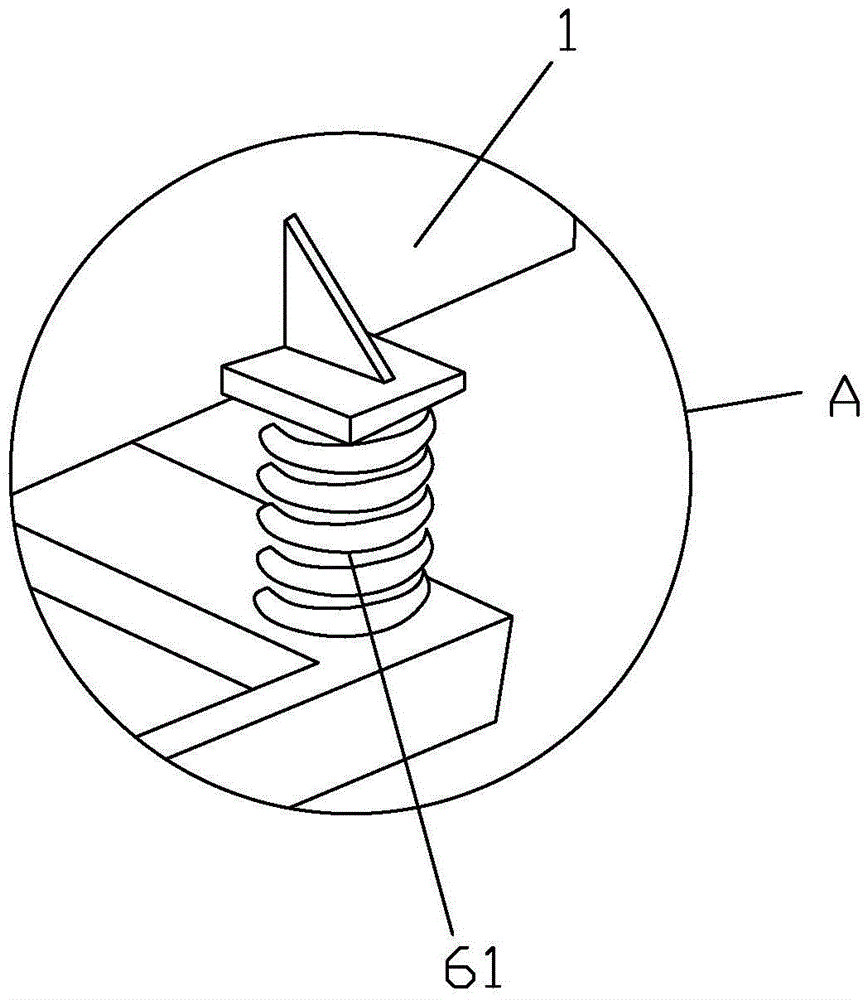

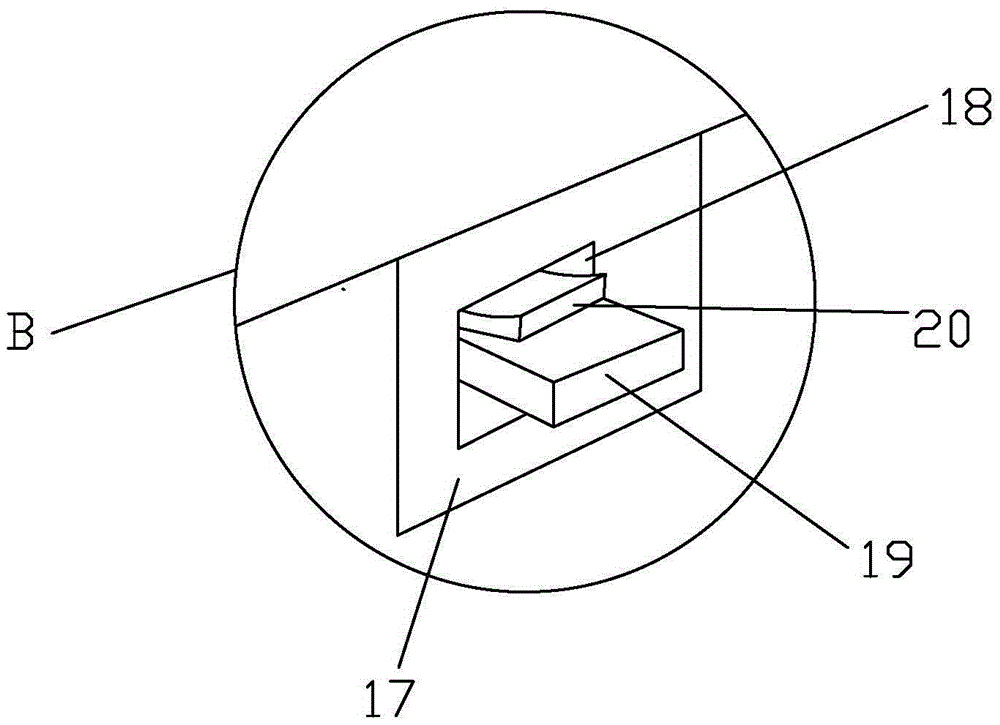

[0021] Such as Figure 1-5 The conveying device includes a base 1 , a support frame 2 , a material inlet 3 , a material outlet 4 , a transmission device 5 and a vibrating device 6 . The support frame 2 is located above the base 1, and the vibration device 6 is located between the support frame 2 and the base 1. The vibration device 6 is composed of a vibration motor 62 and four vibration springs 61, and one end of the vibration springs 61 is respectively connected to On the four corners of the base 1, the other end of the vibration spring 61 is connected to the support frame 2, and the vibration motor 62 drives the support frame 2 to vibrate, thereby driving the plastic particles on the conveyor belt 51 to vibrate, so that the plastic particles are completely shaken away. , disperse, and fully contact with the magnetic stone 511, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com