Regeneration method of waste activated carbon and application

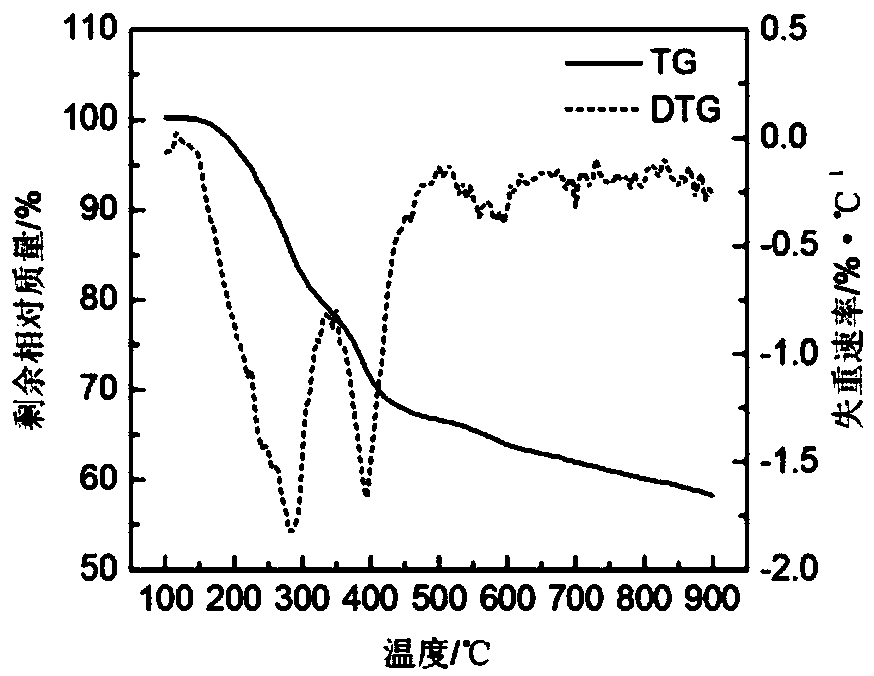

A technology of activated carbon and vacuum pyrolysis, applied in the field of materials, can solve the problems of high cost, large energy consumption of thermal regeneration, small action volume, etc., and achieve the effects of short regeneration cycle, high regeneration efficiency and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

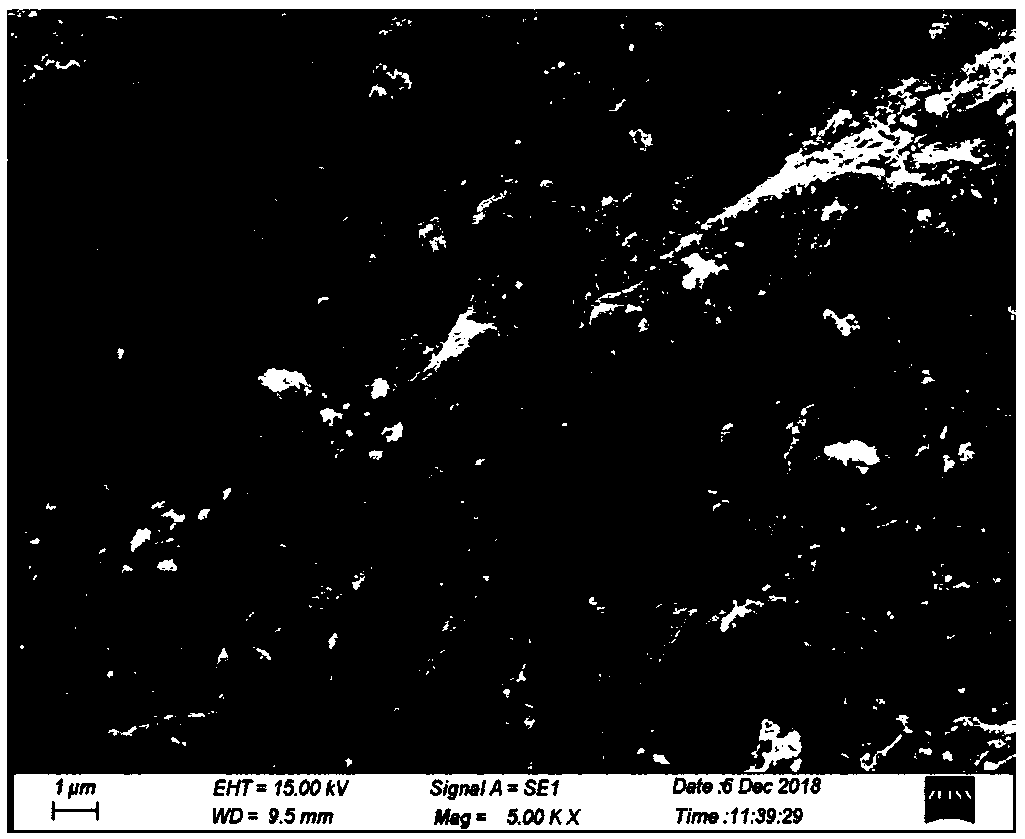

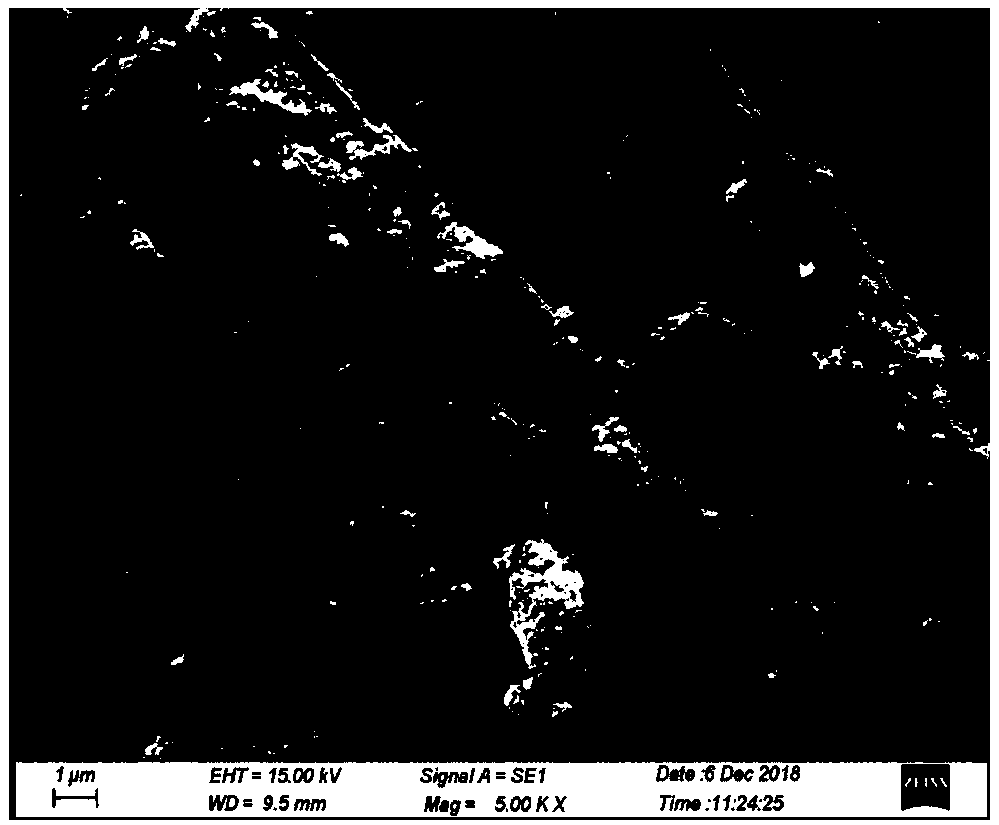

Image

Examples

Embodiment 1

[0045] The waste activated carbon was subjected to vacuum pyrolysis for the first time, the vacuum degree was controlled at 0.06MPa, the heating rate was 5°C / min, the pyrolysis temperature was 250°C, and the holding time was 60min to obtain primary treated activated carbon.

[0046] Mix the primary activated carbon with the regeneration solvent at a material-to-liquid ratio of 50g / L, and shake the shaker to promote the regeneration solvent to diffuse-desorb-dissolve organic matter in the inner pores of the activated carbon. The volume percentage of the regeneration solvent includes 40% methanol, 20% acetone, 20% dichloromethane, 10% ethanol, and 10% isopropanol; The solid and liquid were separated by filtration to obtain activated carbon for secondary treatment.

[0047] After the secondary treatment activated carbon was kept at 200°C for 30 minutes, the temperature was continued to rise to 450°C for the second vacuum pyrolysis, the vacuum degree was 0.08MPa, the heating rate ...

Embodiment 2

[0051] The waste activated carbon in the decolorization stage of pharmaceutical production is subjected to the first vacuum pyrolysis, the vacuum degree is controlled at 0.07MPa, the heating rate is 4°C / min, the pyrolysis temperature is 200°C, and the holding time is 90min to obtain the primary treatment activated carbon. The pigment waste liquid is collected and processed after cooling.

[0052] Mix the primary activated carbon with the regenerated solvent at a material-to-liquid ratio of 200g / L, and shake the shaker to promote the diffusion-desorption-dissolve organic matter of the regenerated solvent in the inner pores of the activated carbon. The volume percentage of the regeneration solvent includes 50% methanol, 15% acetone, 15% methylene chloride, 10% ethanol, and 10% isopropanol; the temperature of the shaker is 50°C, and the shaking speed is 130r / min. The solid-liquid is separated to obtain activated carbon for secondary treatment, and the filtrate is collected in a f...

Embodiment 3

[0056] The waste activated carbon in the decolorization stage of pharmaceutical production is subjected to the first vacuum pyrolysis, the vacuum degree is controlled at 0.08MPa, the heating rate is 3°C / min, the pyrolysis temperature is 220°C, and the holding time is 30min to obtain the primary treatment activated carbon. The pigment waste liquid is collected and processed after cooling.

[0057] Mix the primary activated carbon with the regeneration solvent at a material-to-liquid ratio of 100g / L, and shake the shaker to promote the diffusion-desorption-dissolve organic matter of the regeneration solvent in the inner pores of the activated carbon. The volume percentage of the regeneration solvent includes 45% methanol, 18% acetone, 17% dichloromethane, 10% ethanol, and 10% isopropanol; The solid-liquid is separated by filtration to obtain activated carbon for secondary treatment, and the filtrate is collected in a filtrate collection bottle.

[0058] After the secondary trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com