Y-Beta composite molecular sieve having double mesoporous structure, and preparation method thereof

A composite molecular sieve, double mesoporous technology, applied in the direction of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problem of inability to handle aromatic macromolecules, achieve excellent catalytic activity, increase acid content, reduce The effect of silicon aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

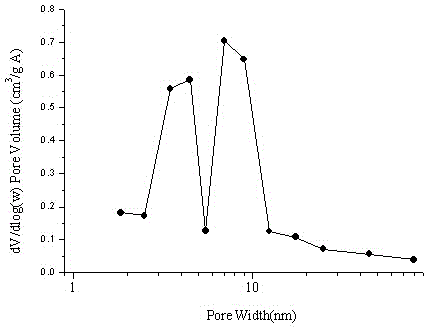

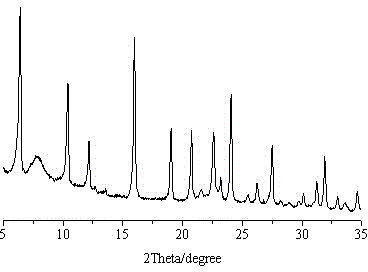

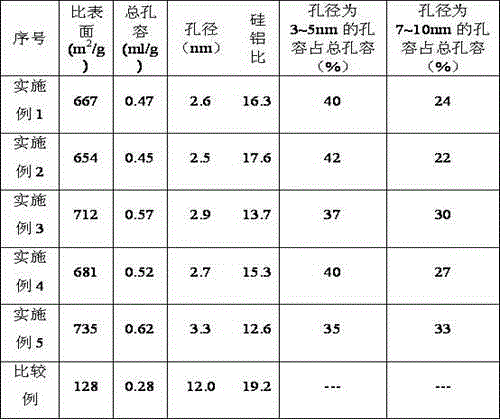

[0024] Mix sodium hydroxide and water, and heat to 60°C in a water bath under stirring conditions, then add tetrapropylammonium hydroxide, and finally add Y-Beta composite molecular sieve, continue to stir at constant temperature for 2 hours, cool, and suction filter to The pH value is less than 9, dried at 110°C for 12 hours, and finally roasted at 550°C for 4 hours to remove residual organic matter. Finally, the Y-Beta composite molecular sieve after alkali treatment is subjected to ammonium exchange to obtain the double mesoporous Y-Beta composite molecular sieve. The concentration of the sodium hydroxide solution is 0.48mol / L, the concentration of tetrapropylammonium hydroxide in the sodium hydroxide solution is 0.12mol / L, and the mass ratio of water to molecular sieves is 8. The specific properties of the double mesoporous Y-Beta composite molecular sieve are shown in Table 1.

Embodiment 2

[0026] Mix sodium hydroxide and water, and heat to 75°C in a water bath under stirring conditions, then add tetrabutylammonium hydroxide, and finally add Y-Beta composite molecular sieves, continue to stir at constant temperature for 1.5 hours, cool, and suction filter to the pH value If it is less than 9, dry at 110°C for 24 hours, and finally bake at 500°C for 5 hours to remove residual organic matter. Finally, the alkali-treated Y-Beta composite molecular sieve is subjected to ammonium exchange to obtain a double mesoporous Y-Beta composite molecular sieve. The concentration of the sodium hydroxide solution is 0.49mol / L, the concentration of tetrabutylammonium hydroxide in the sodium hydroxide solution is 0.12mol / L, and the mass ratio of water to molecular sieve is 11. The specific properties of the double mesoporous Y-Beta composite molecular sieve are shown in Table 1.

Embodiment 3

[0028] Mix sodium hydroxide and water, and heat to 65°C in a water bath under stirring conditions, then add tetraethylammonium hydroxide, and finally add Y-Beta composite molecular sieves, continue to stir at constant temperature for 2 hours, cool, and suction filter to The pH value is less than 9, dried at 90°C for 18 hours, and finally roasted at 540°C for 6 hours to remove residual organic matter. Finally, the alkali-treated Y-Beta composite molecular sieve is subjected to ammonium exchange to obtain a double mesoporous Y-Beta composite molecular sieve. The concentration of the sodium hydroxide solution is 0.60 mol / L, the concentration of tetraethylammonium hydroxide in the sodium hydroxide solution is 0.11 mol / L, and the mass ratio of water to molecular sieves is 9. The specific properties of the double mesoporous Y-Beta composite molecular sieve are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com