Separation tank for oil-containing waste water

A separation tank and wastewater technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor separation effect, difficult separation and difficult separation of oil substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

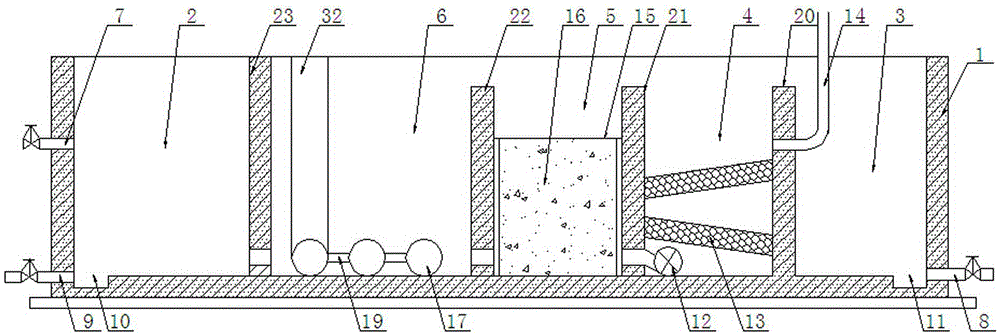

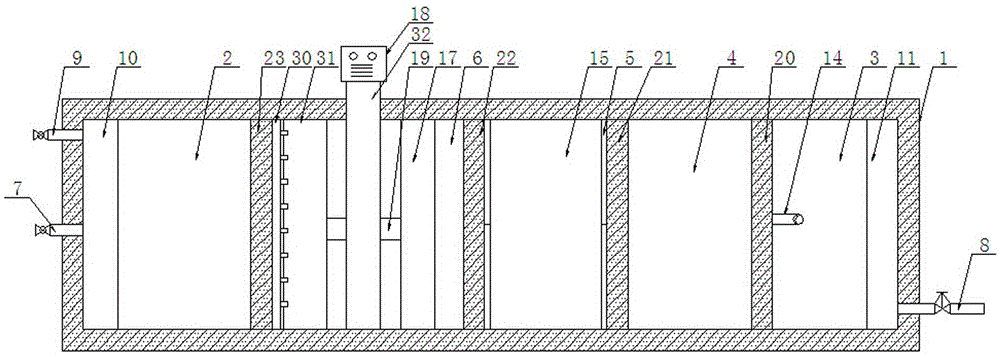

[0028] An oily waste water separation tank, comprising a rectangular pool body 1, four blocks are fixedly arranged in the pool body 1 for sequentially dividing the pool body 1 into an oil discharge chamber 3, a primary separation chamber 4, a secondary separation chamber 5, The partition wall of the third-stage separation chamber 6 and the drainage chamber 2, the bottom of the oil discharge chamber 3 is provided with an oil discharge port 8, and the oil discharge chamber 3 communicates with the upper part of the primary separation chamber 4; the primary separation chamber 4 A submersible pump 12, an activated carbon adsorption layer and a water inlet pipe 14 are arranged inside, the submersible pump 12 is arranged at the lower part of the primary separation chamber 4, and the water outlet end of the submersible pump 12 is located at the lower part of the secondary separation chamber 5, and the water inlet pipe 14 Set above the submersible pump 12, the activated carbon adsorptio...

Embodiment 2

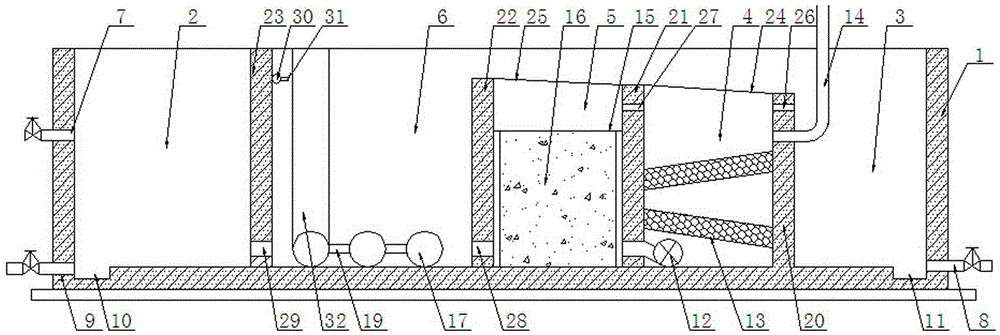

[0037] An oily waste water separation tank, comprising a rectangular pool body 1, four blocks are fixedly arranged in the pool body 1 for sequentially dividing the pool body 1 into an oil discharge chamber 3, a primary separation chamber 4, a secondary separation chamber 5, The partition wall of the third-stage separation chamber 6 and the drainage chamber 2, the bottom of the oil discharge chamber 3 is provided with an oil discharge port 8, and the oil discharge chamber 3 communicates with the upper part of the primary separation chamber 4; the primary separation chamber 4 A submersible pump 12, an activated carbon adsorption layer and a water inlet pipe 14 are arranged inside, the submersible pump 12 is arranged at the lower part of the primary separation chamber 4, and the water outlet end of the submersible pump 12 is located at the lower part of the secondary separation chamber 5, and the water inlet pipe 14 Set above the submersible pump 12, the activated carbon adsorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com