Steam cracking method

A cracking furnace and dilution steam technology, applied in the field of steam cracking, can solve problems such as coking in the convection section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] This example is used to illustrate the steam cracking method provided by the present invention.

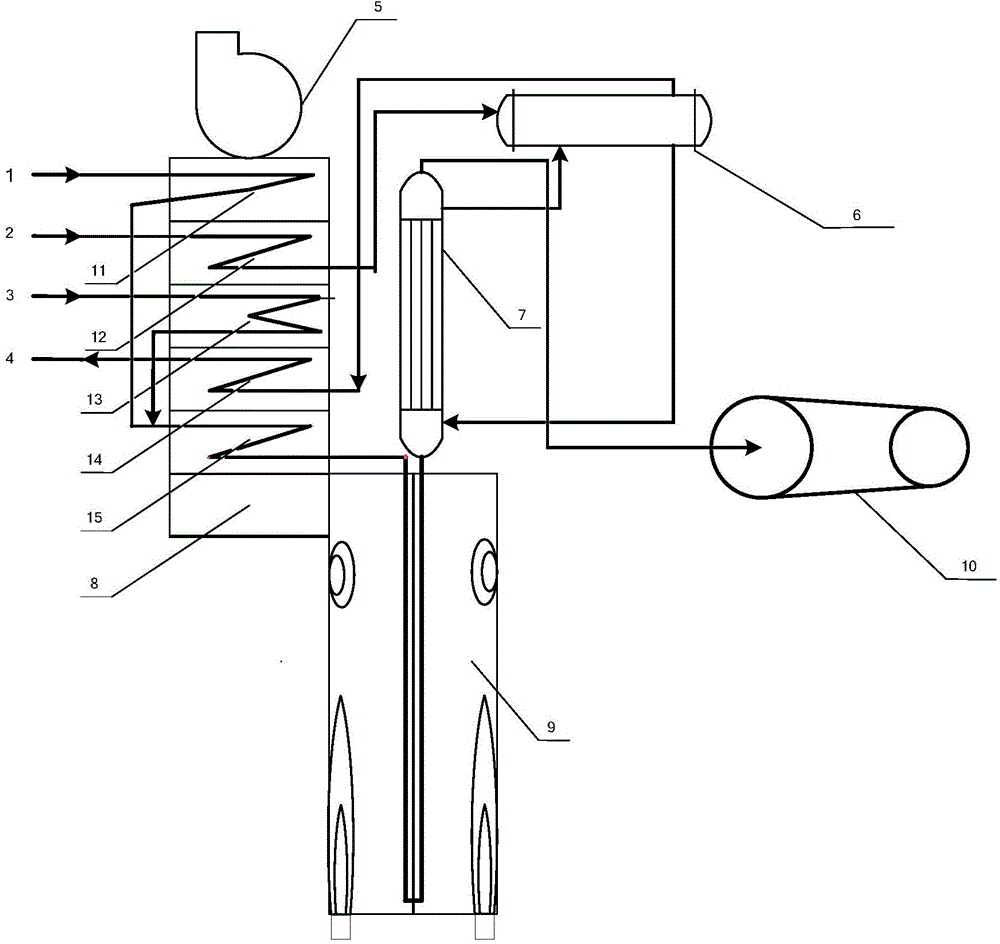

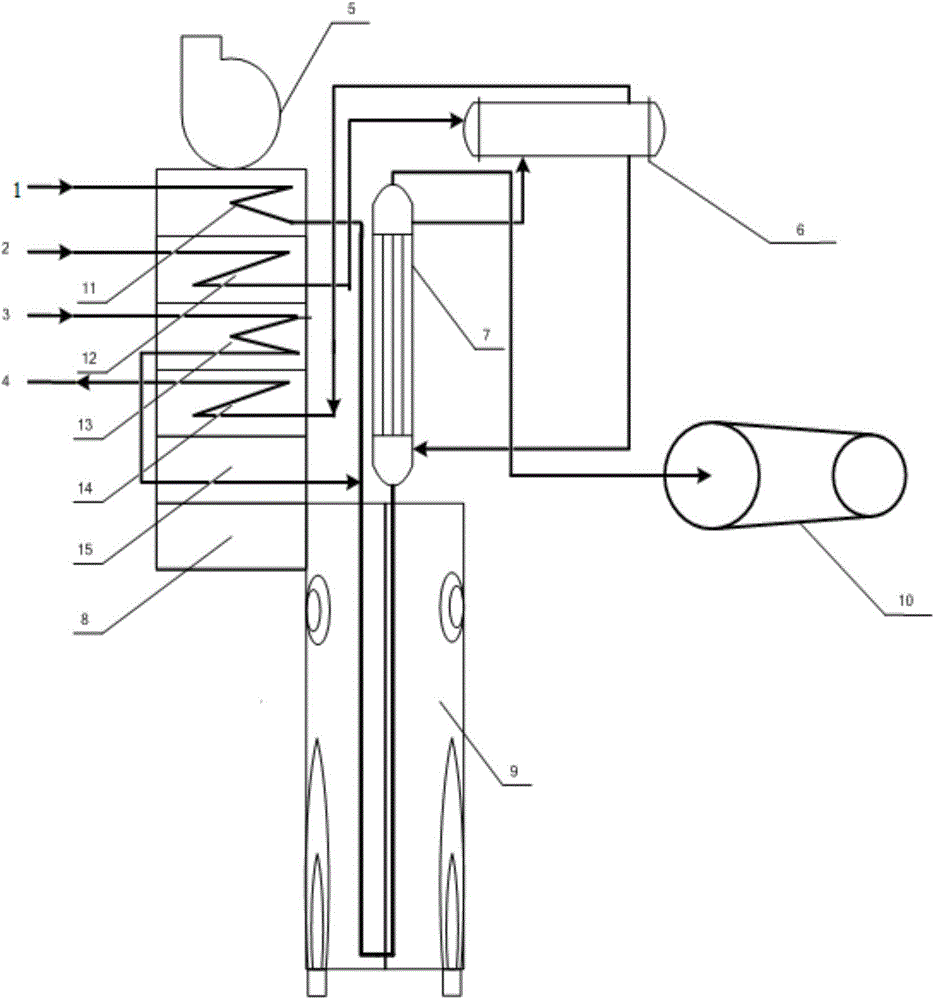

[0057] use figure 2 The cleavage apparatus shown performs the cleavage reaction. The specific process includes:

[0058] C4, C5 and C6 olefins (composition as shown in Table 1) are vaporized in a vaporization device; the dilution steam 3 is preheated through the raw material preheating section 11 in the convection section of the cracking furnace, and the unsaturated hydrocarbon The weight ratio of 1 and the amount of the dilution steam 3 is 1:0.4; then the vaporized gas phase unsaturated hydrocarbon is mixed with the gas of the dilution steam preheated by the raw material preheating section 11 to obtain a cracking raw material mixture; Then a part of this cracking raw material mixture is introduced from the radiant section 9 outlet of cracking furnace, and another part is introduced from the top of the radiant section 9 of cracking furnace and carries out cracking reacti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com