Method for preparing self-assembled all-carbon three-dimensional graphene with papermaking black liquor

A paper-making black liquor and self-assembly technology, applied in the direction of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems of reducing the quality of graphene, low production efficiency of 3D graphene, etc., and achieve the effect of overcoming agglomeration and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

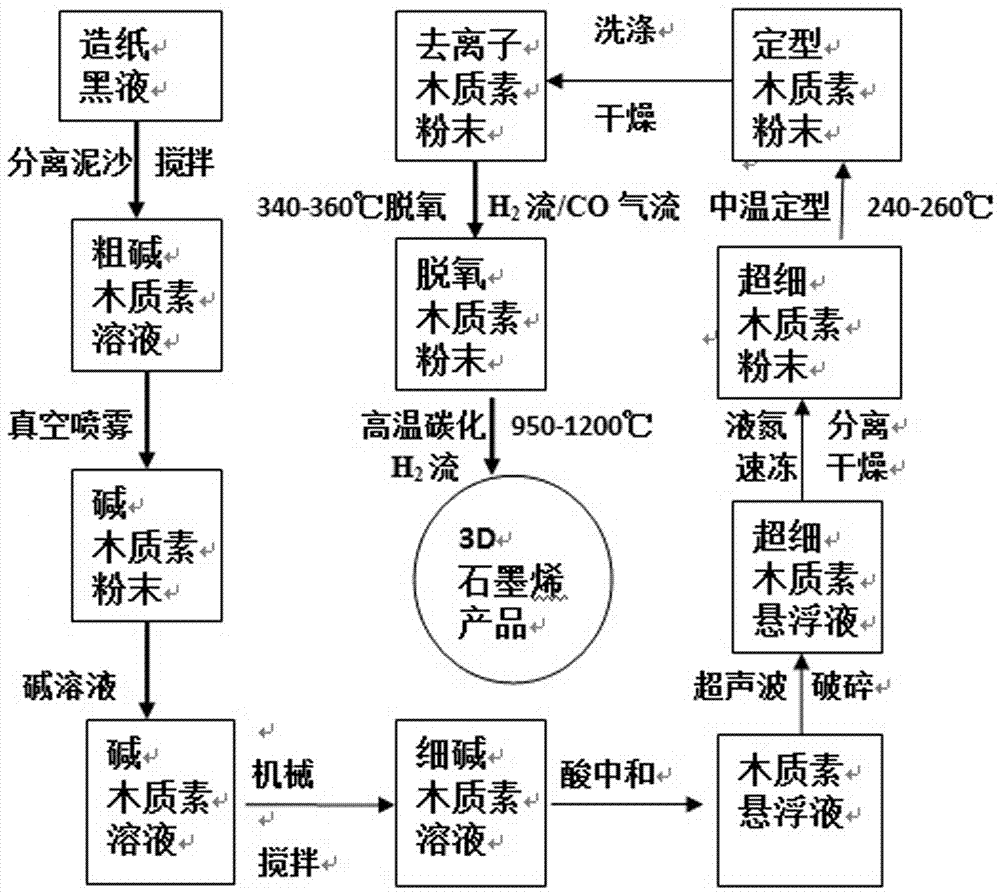

[0044] The method for preparing self-assembled full-carbon three-dimensional graphene with papermaking black liquor in the present invention adopts the technical scheme including the following steps: (1) stirring and separating sediment; (2) vacuum spray drying; (3) mechanical stirring and alkali dissolution; (4) ) Acid neutralization; (5) Ultrasonic pulverization; (6) Liquid nitrogen quick-freeze drying; (7) Moderate temperature curing and setting; (8) Deionized water washing; (9) Constant temperature oven drying; (10) Moderate temperature hydrogen reduction deoxidation ; (11) High temperature carbonization treatment. Only the strict combination of these 11 steps can achieve good results, and the most critical steps of the present invention are steps (7), (8) and (9). Therefore, in order to verify the effect of the preparation scheme of the present invention, in this example In 1, step (7), step (8) and step (9) are omitted. The specific implementation process is as follows:...

Embodiment 2

[0056] Compared with Example 1, the method of preparing self-assembled full-carbon three-dimensional graphene with papermaking black liquor in Example 2 includes the following steps: (1) stirring and separating sediment; (2) vacuum spray drying; (3) mechanical (4) Acid neutralization; (5) Ultrasonic pulverization; (6) Liquid nitrogen quick freeze drying; (7) Medium temperature solidification; (8) Deionized water washing; (9) Constant temperature box drying; ( 10) Medium-temperature hydrogen reduction deoxidation; (11) High-temperature carbonization treatment. The specific implementation process is as follows:

[0057] (1) Take 10 liters of poplar papermaking black liquor and put it into a separation container. After being fully stirred by a stirrer, settle for 3 hours, and discharge the part containing sediment in the lower layer.

[0058] (2) Take the black liquor containing alkali lignin in the upper layer and carry out vacuum spray drying treatment with a vacuum dryer to o...

Embodiment 3

[0071] The method for preparing self-assembled full-carbon three-dimensional graphene with papermaking black liquor in the present invention adopts the technical scheme including the following steps: (1) stirring and separating sediment; (2) vacuum spray drying; (3) mechanical stirring and alkali dissolution; (4) ) Acid neutralization; (5) Ultrasonic pulverization; (6) Liquid nitrogen quick-freeze drying; (7) Moderate temperature curing and setting; (8) Deionized water washing; (9) Constant temperature oven drying; (10) Moderate temperature hydrogen reduction deoxidation ; (11) High temperature carbonization treatment. The specific process is as follows:

[0072] (1) Take 10 liters of eucalyptus papermaking black liquor and put it into a separation container. After being fully stirred by the agitator, settle for 4 hours, and discharge the part containing sediment in the lower layer.

[0073] (2) Take the black liquor containing alkali lignin in the upper layer and carry out v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com