Patents

Literature

32results about How to "Overcome coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

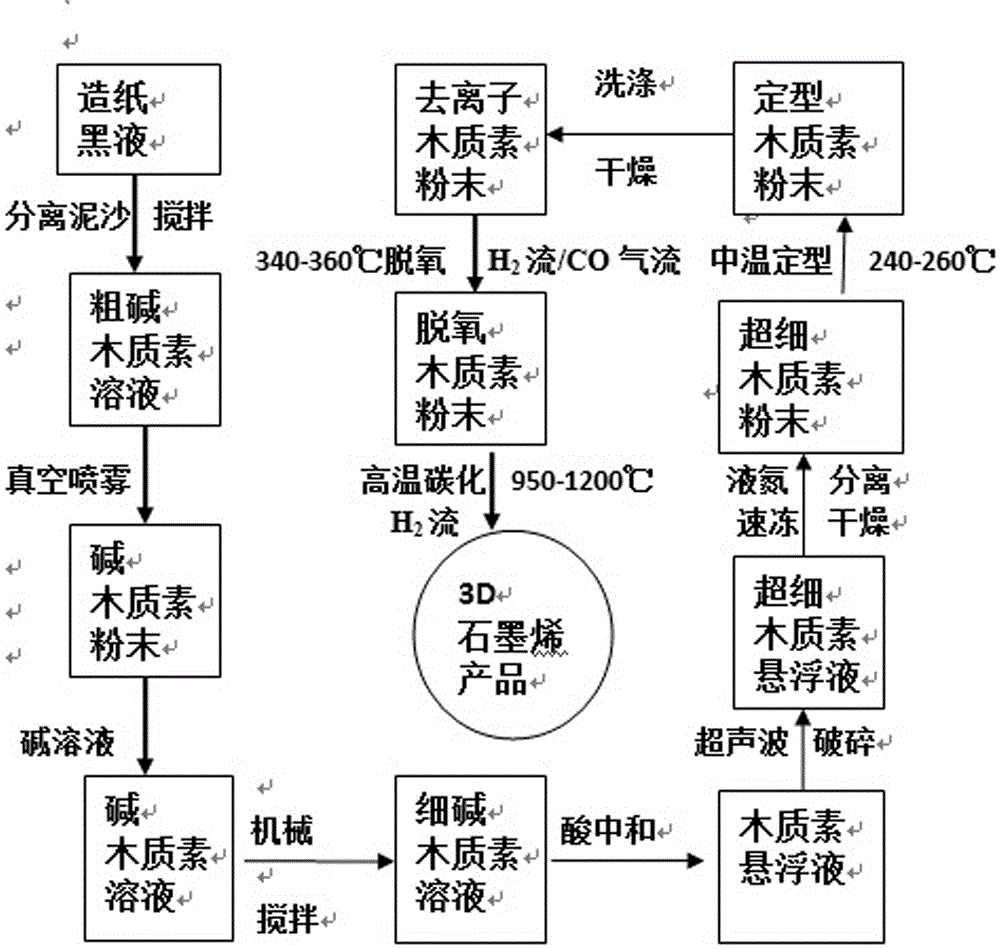

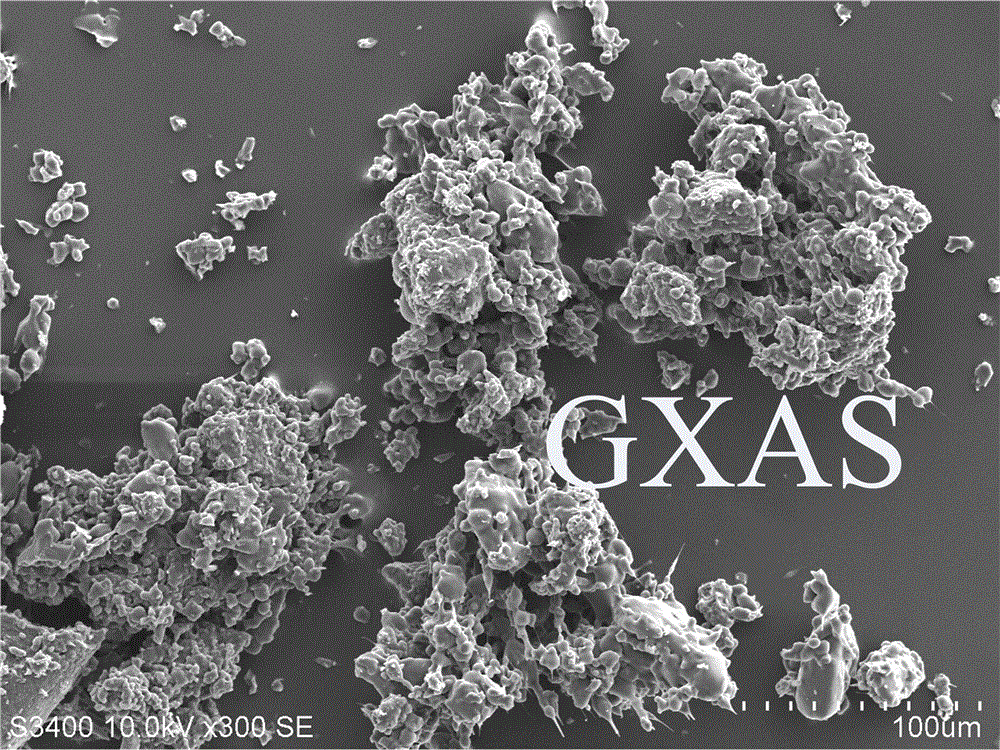

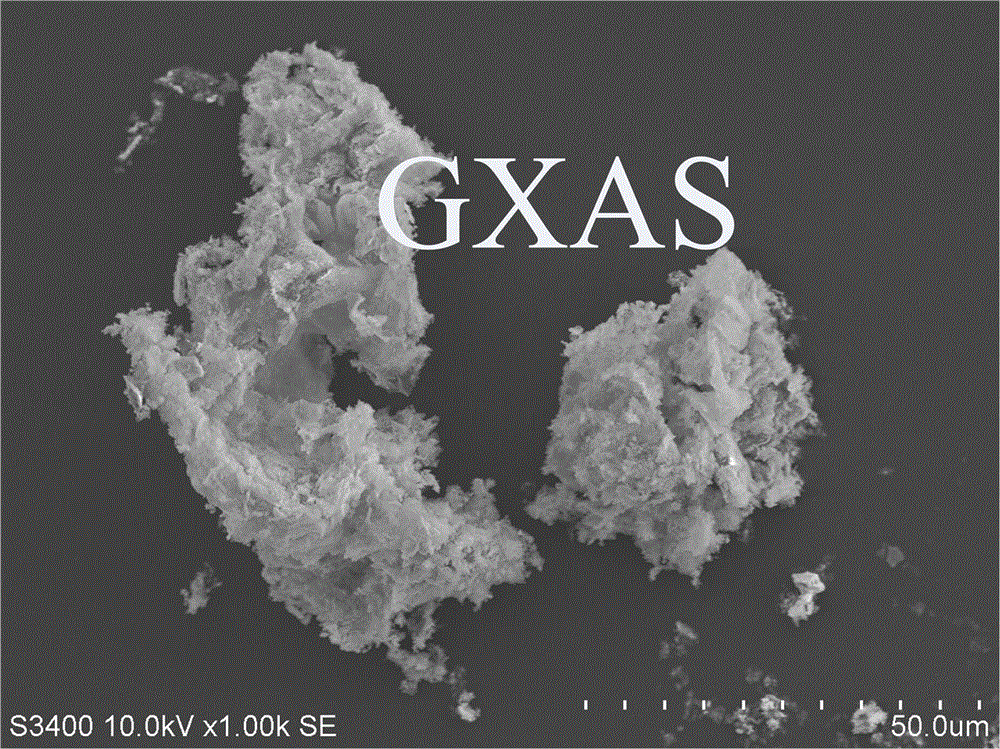

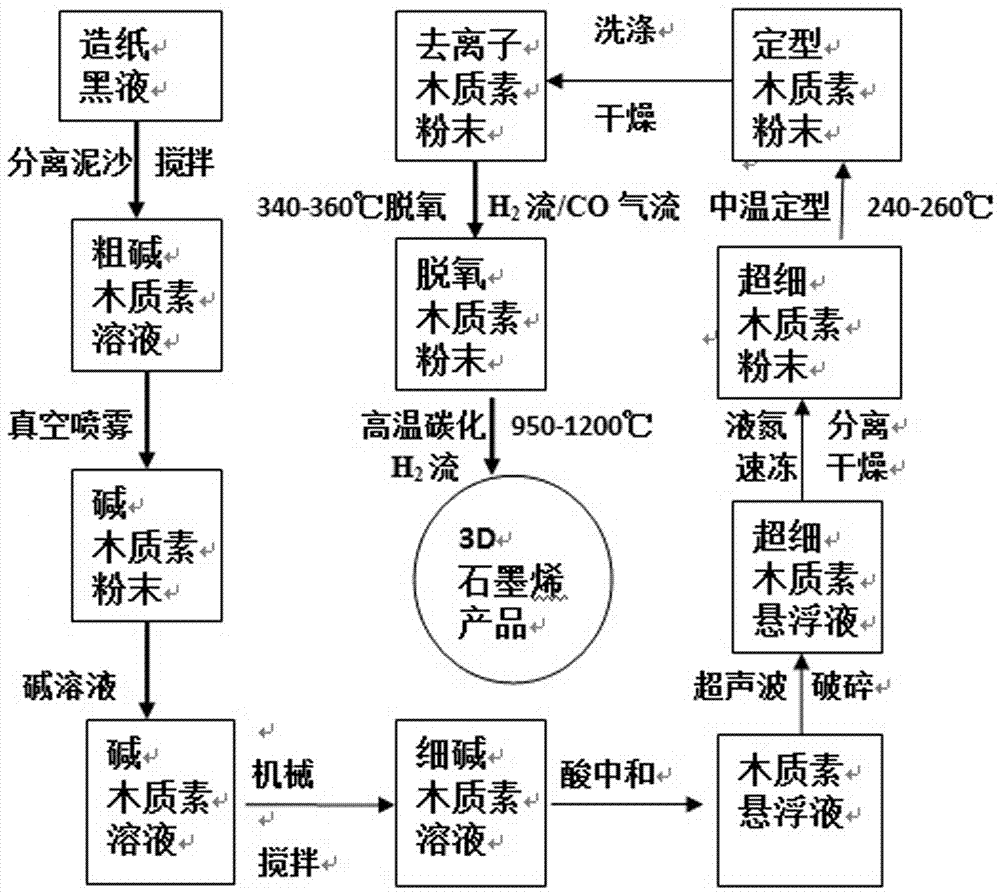

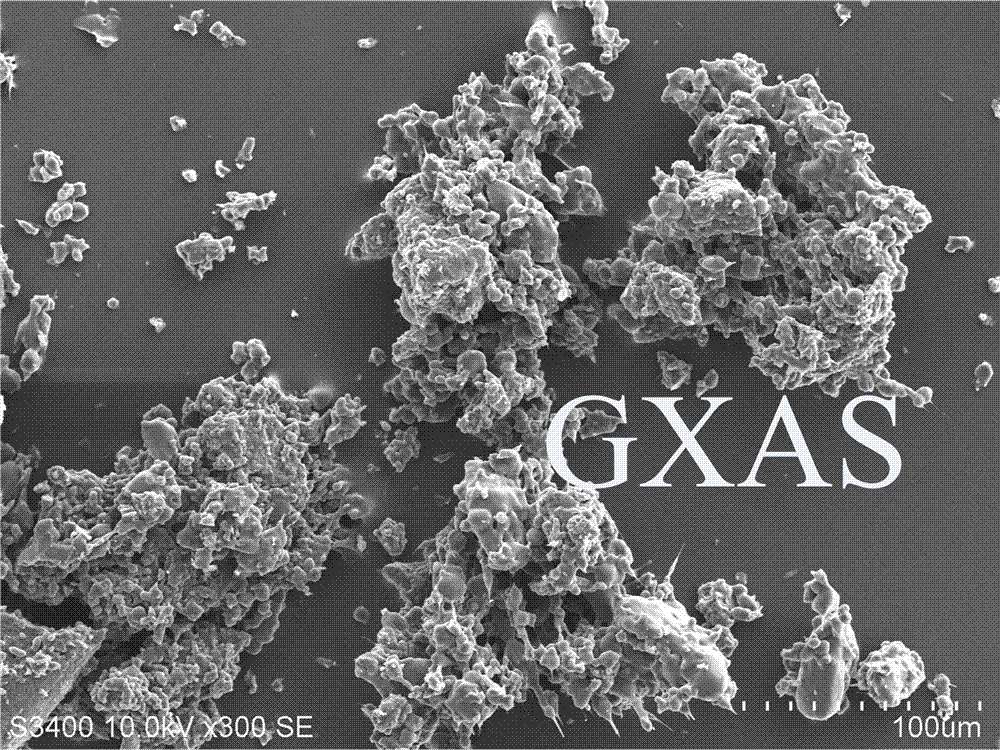

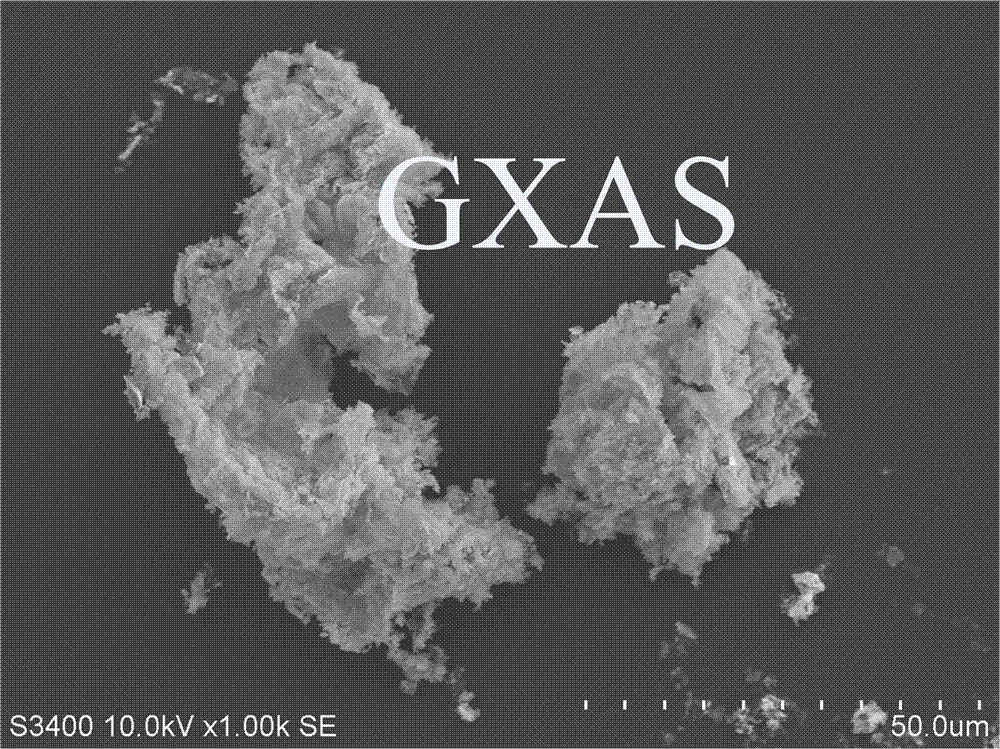

Method for preparing self-assembly all-carbon three-dimensional graphene from papermaking black liquid

ActiveCN105600779AMaintain three-dimensional structureReduce conductivityGrapheneCarbonizationLiquid nitrogen

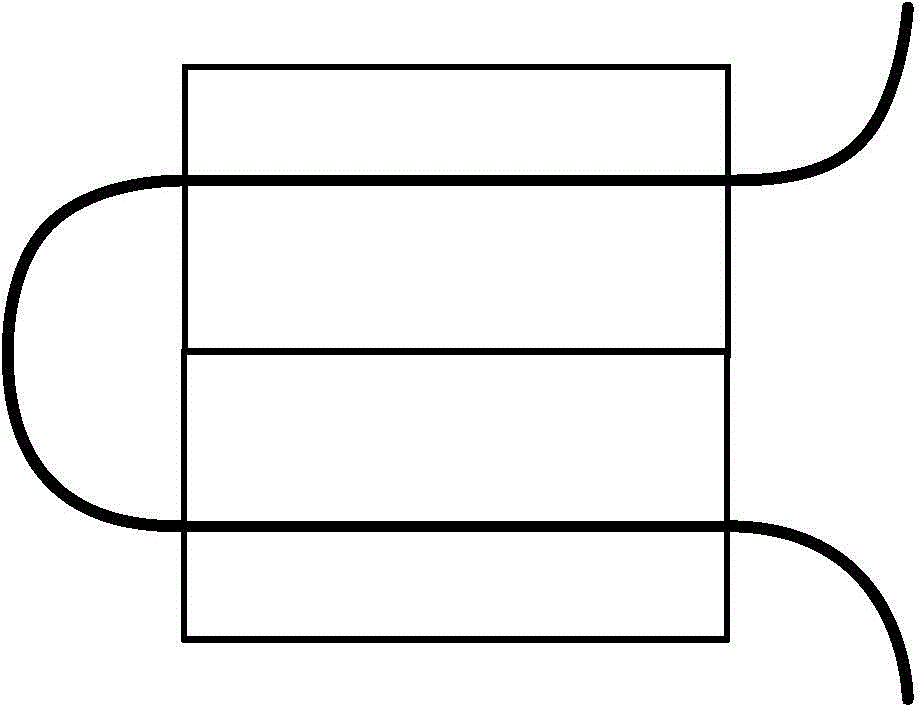

The invention discloses a method for preparing self-assembly all-carbon three-dimensional graphene from papermaking black liquid. The method includes the steps of ultrasonically smashing lignin suspension liquid, using liquid nitrogen quick freezing for drying and shape maintenance, conducting medium temperature partial carbonization shaping and solidifying and performing multi-temperature multi-atmosphere procedural deoxidation carbonization treatment. Treated lignin can be kept of a loose and porous three-dimensional structure in the high-temperature carbonization process, coking and caking which are prone to occurring are avoided, the self-assembly all-carbon three-dimensional graphene material with a supporting structure is prepared, all fragments are fused closely, multiple layers are distributed in a three-dimensional mode and support one another, structural stability is enhanced, and the superficial area of graphene is increased.

Owner:GUANGXI ACAD OF SCI

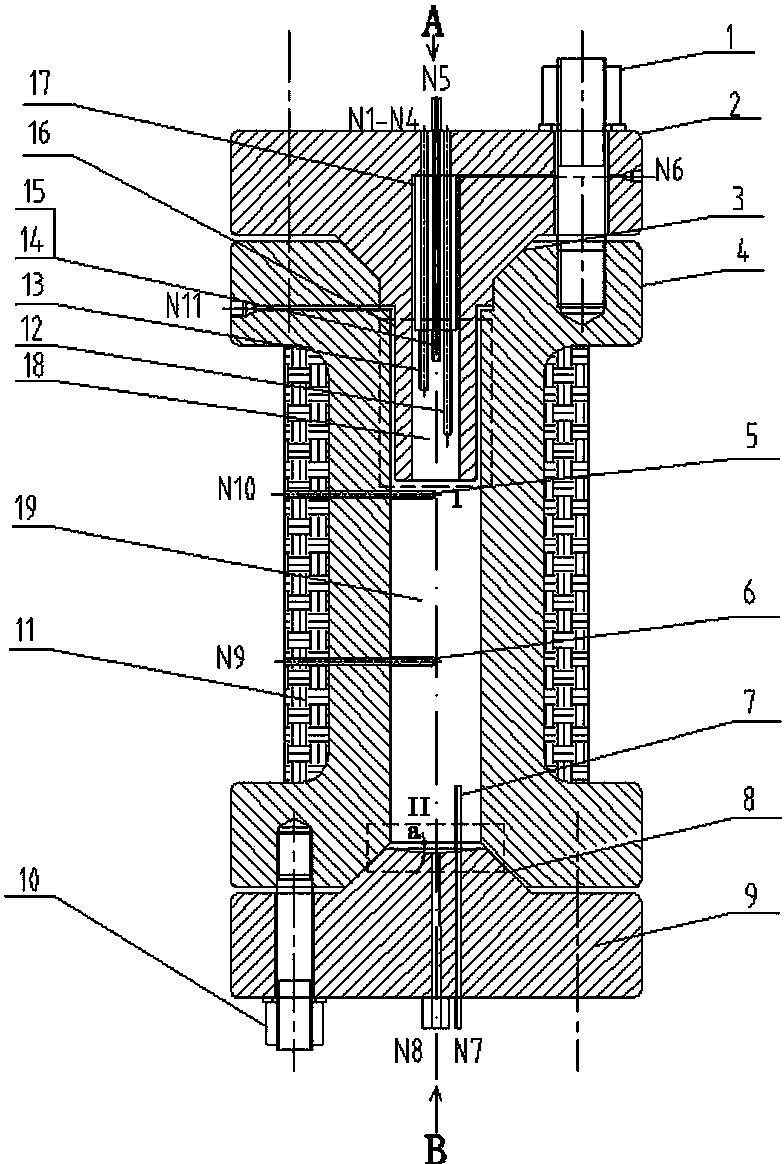

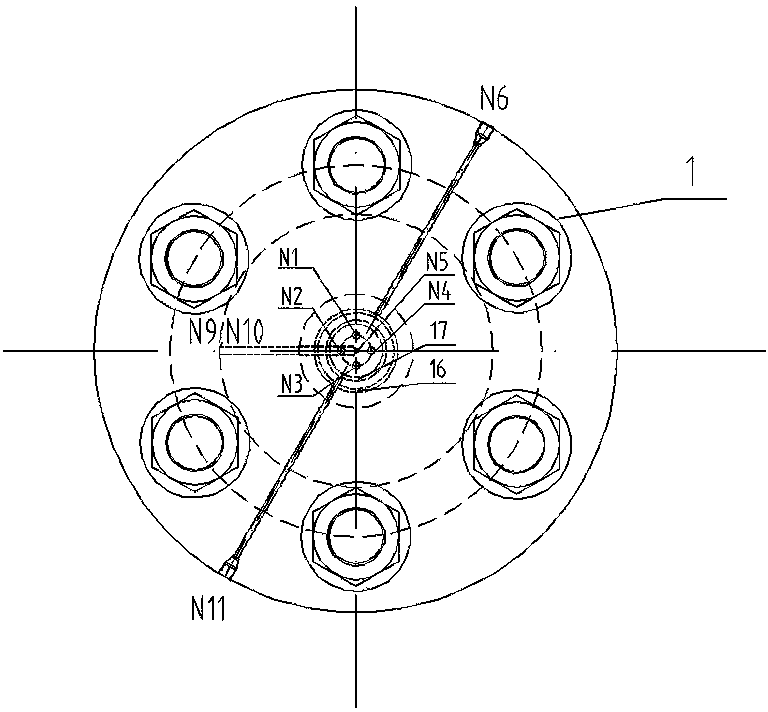

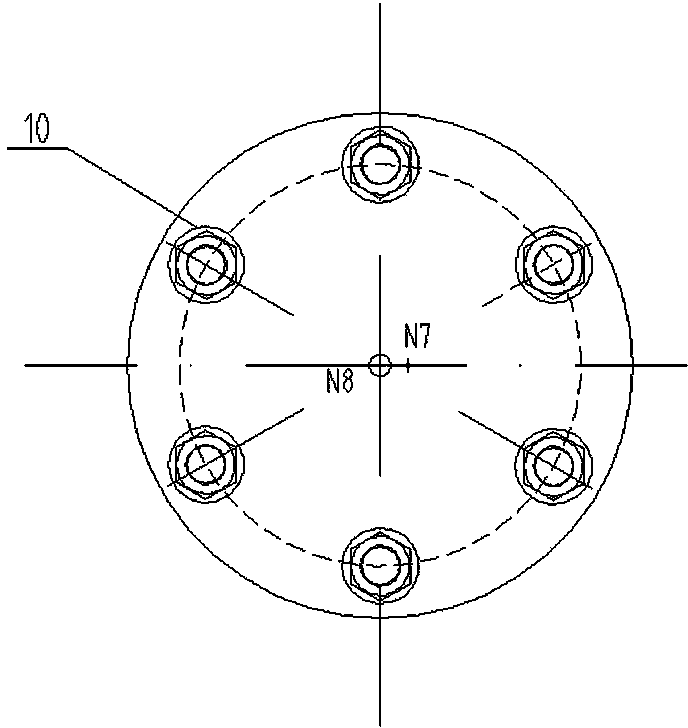

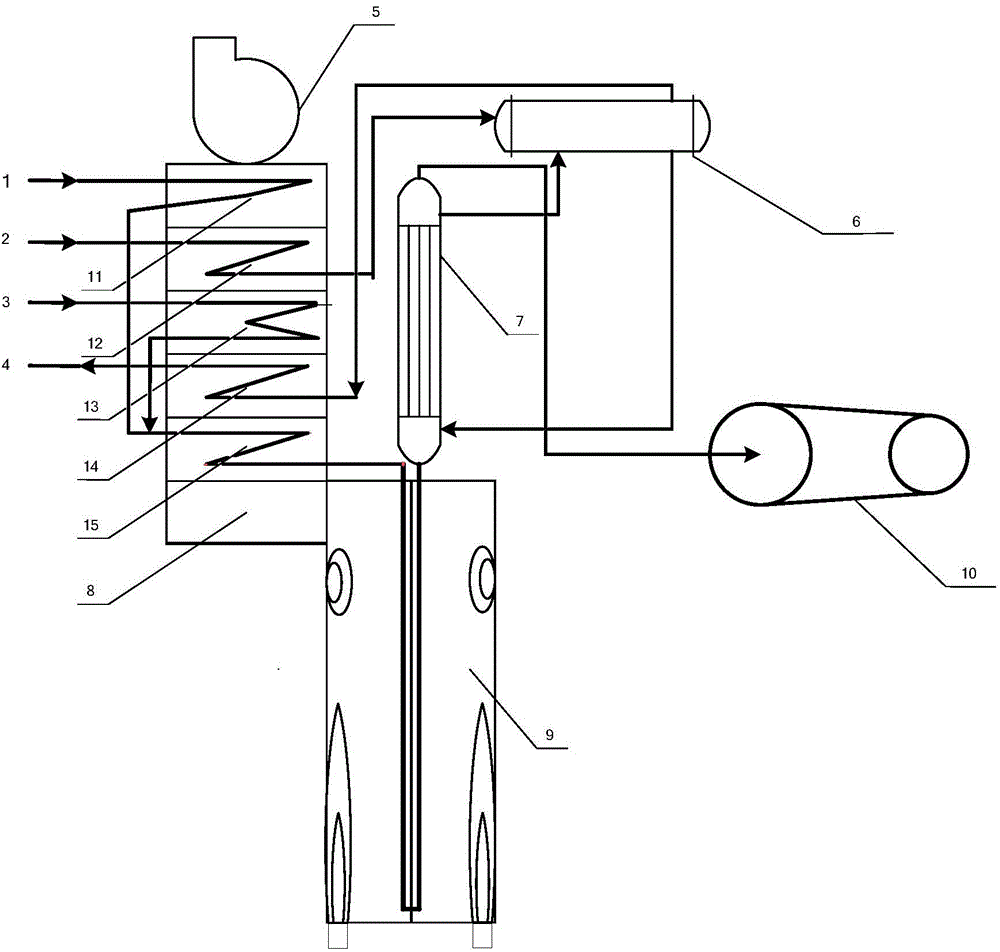

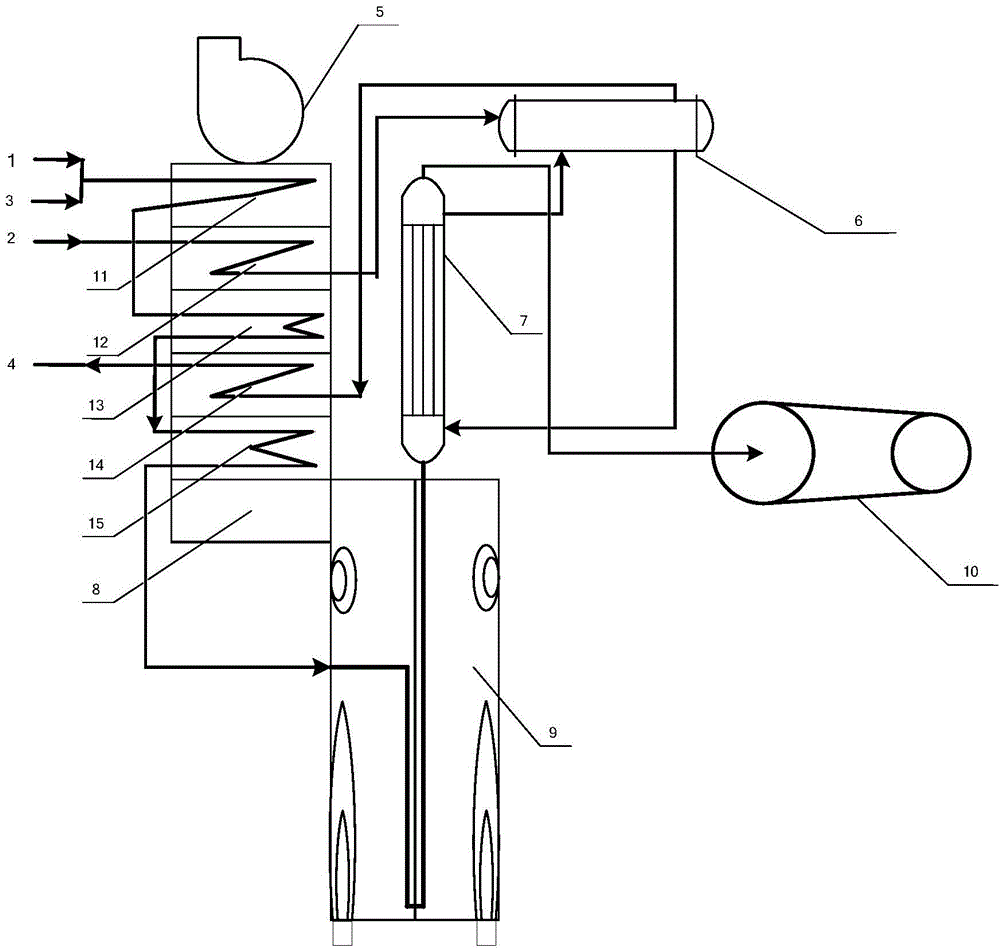

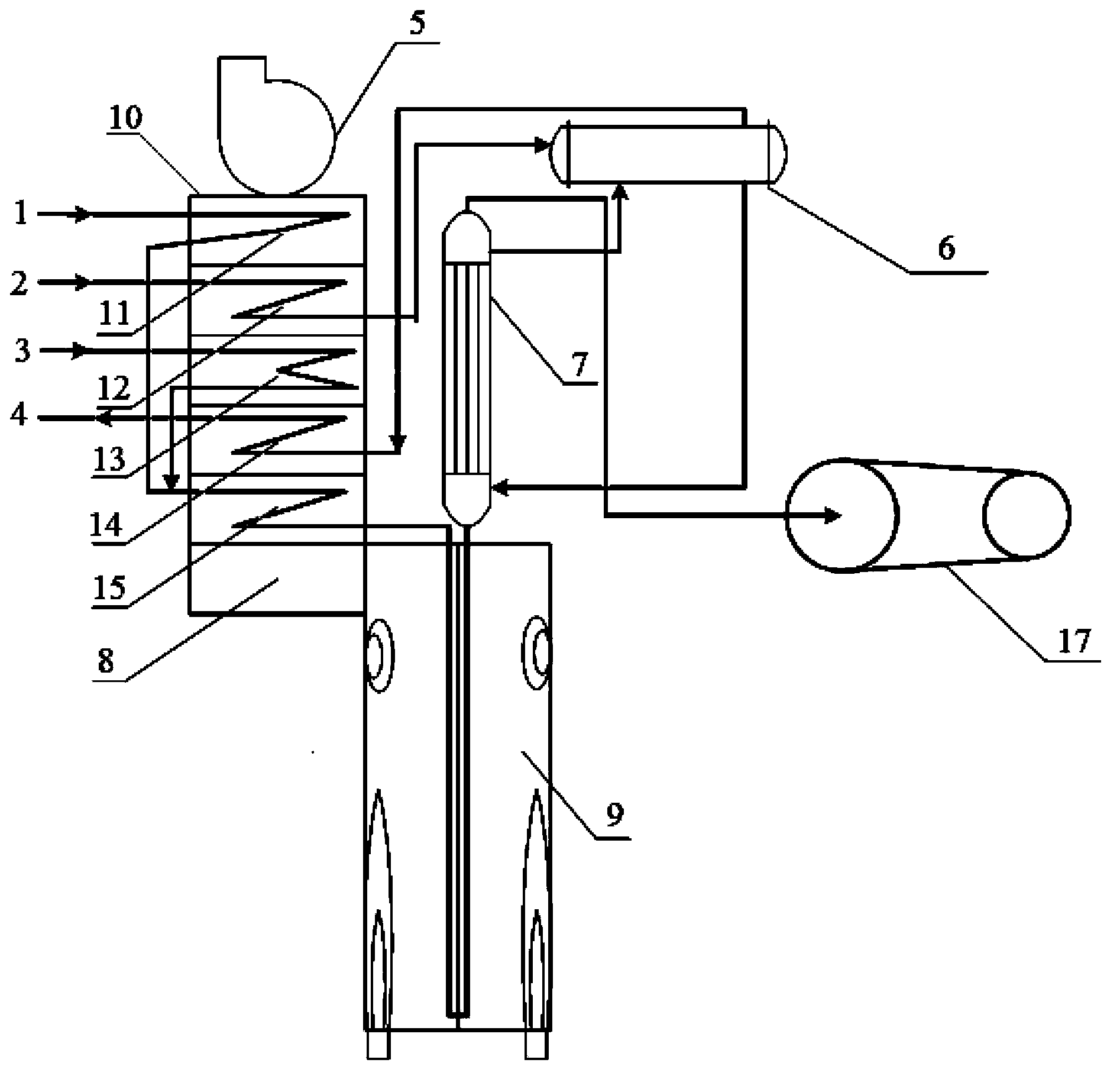

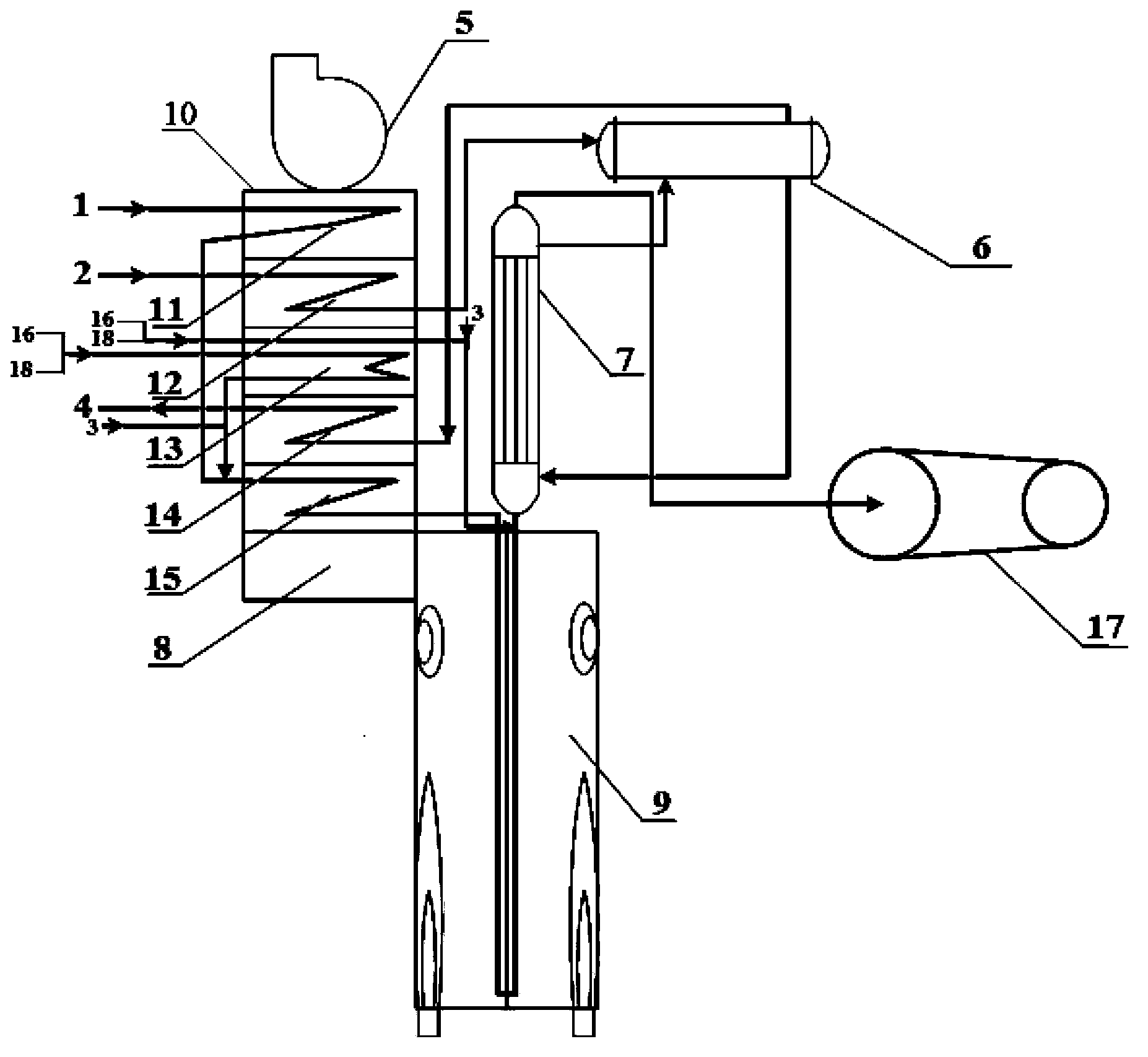

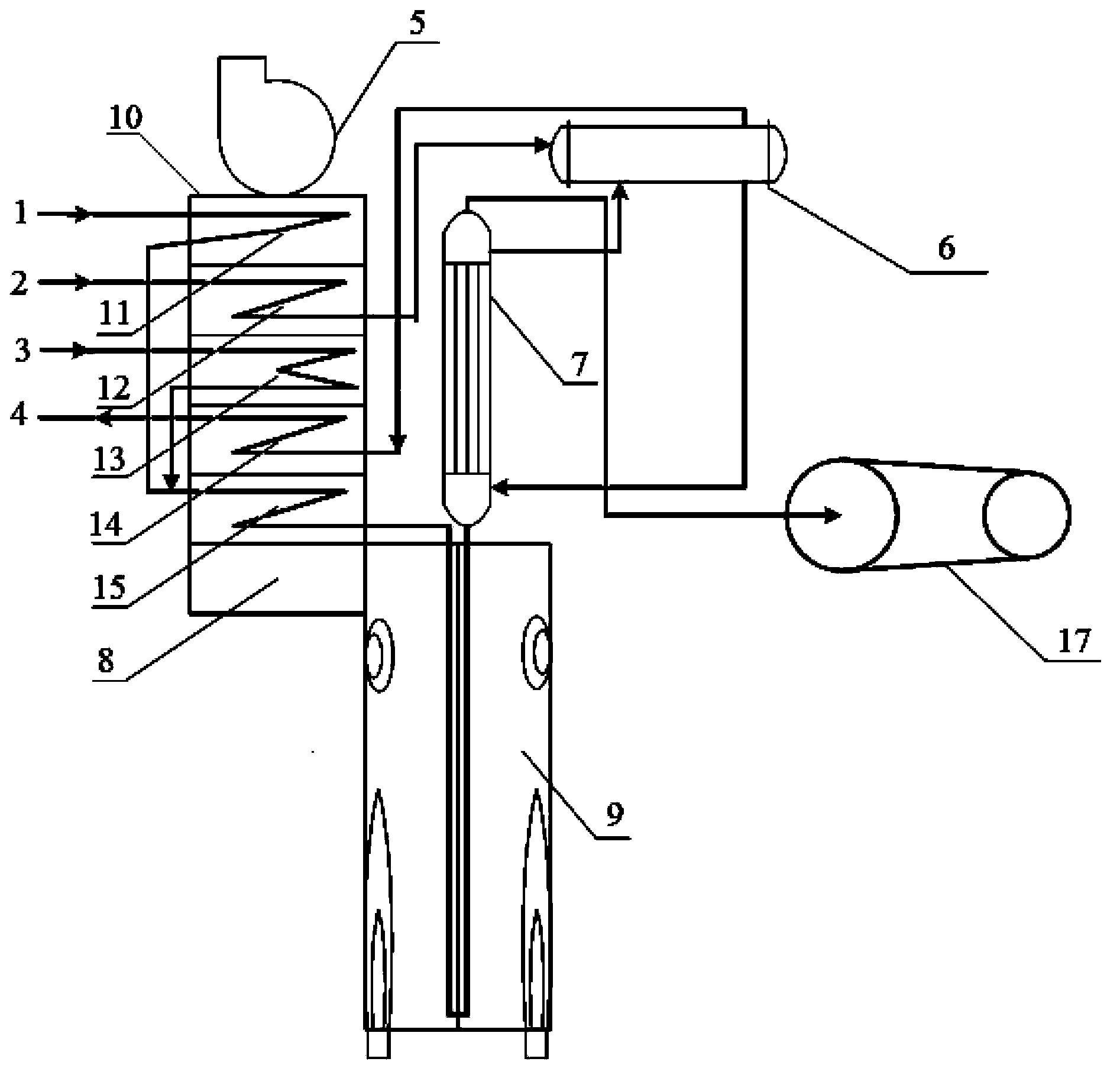

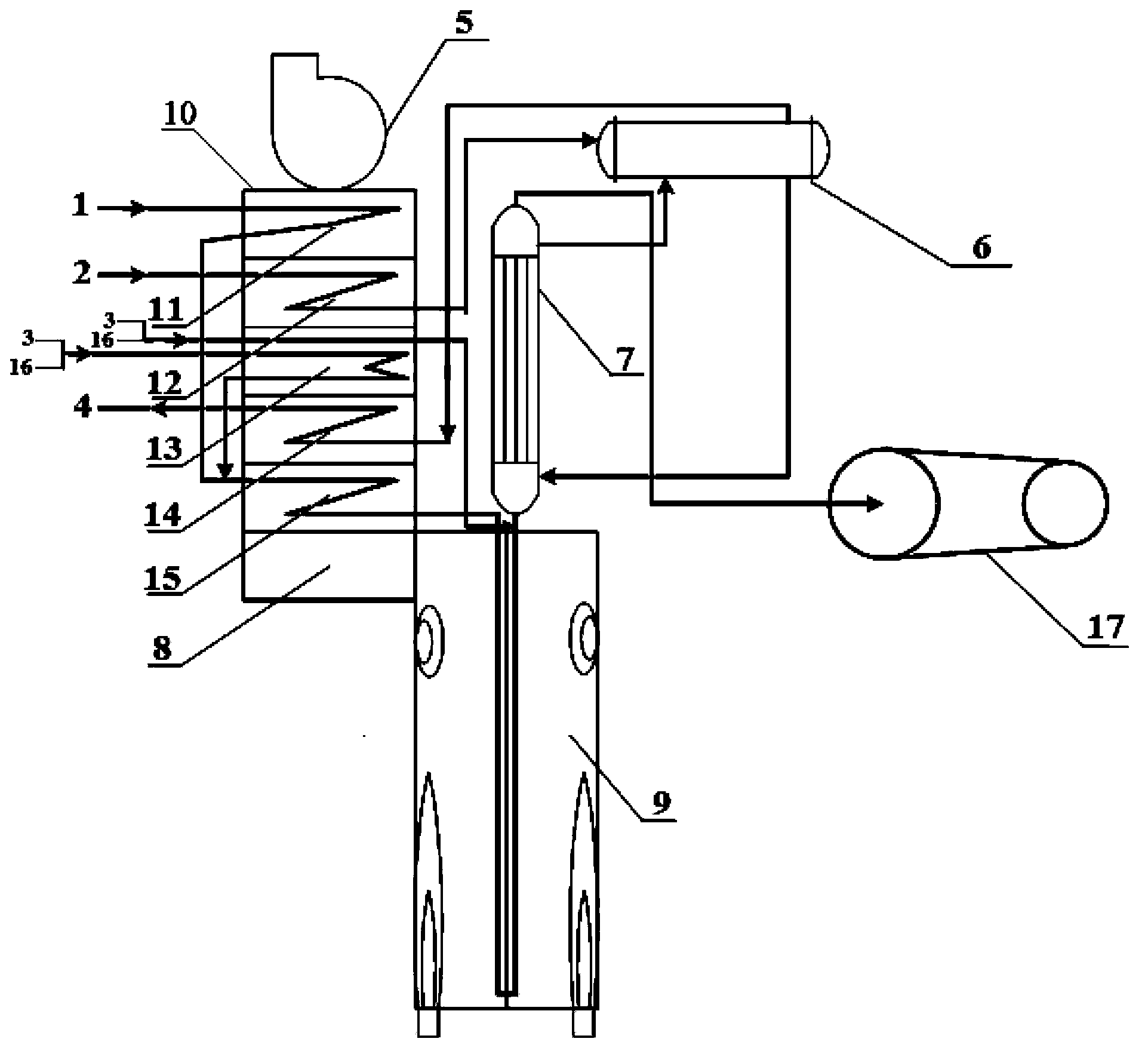

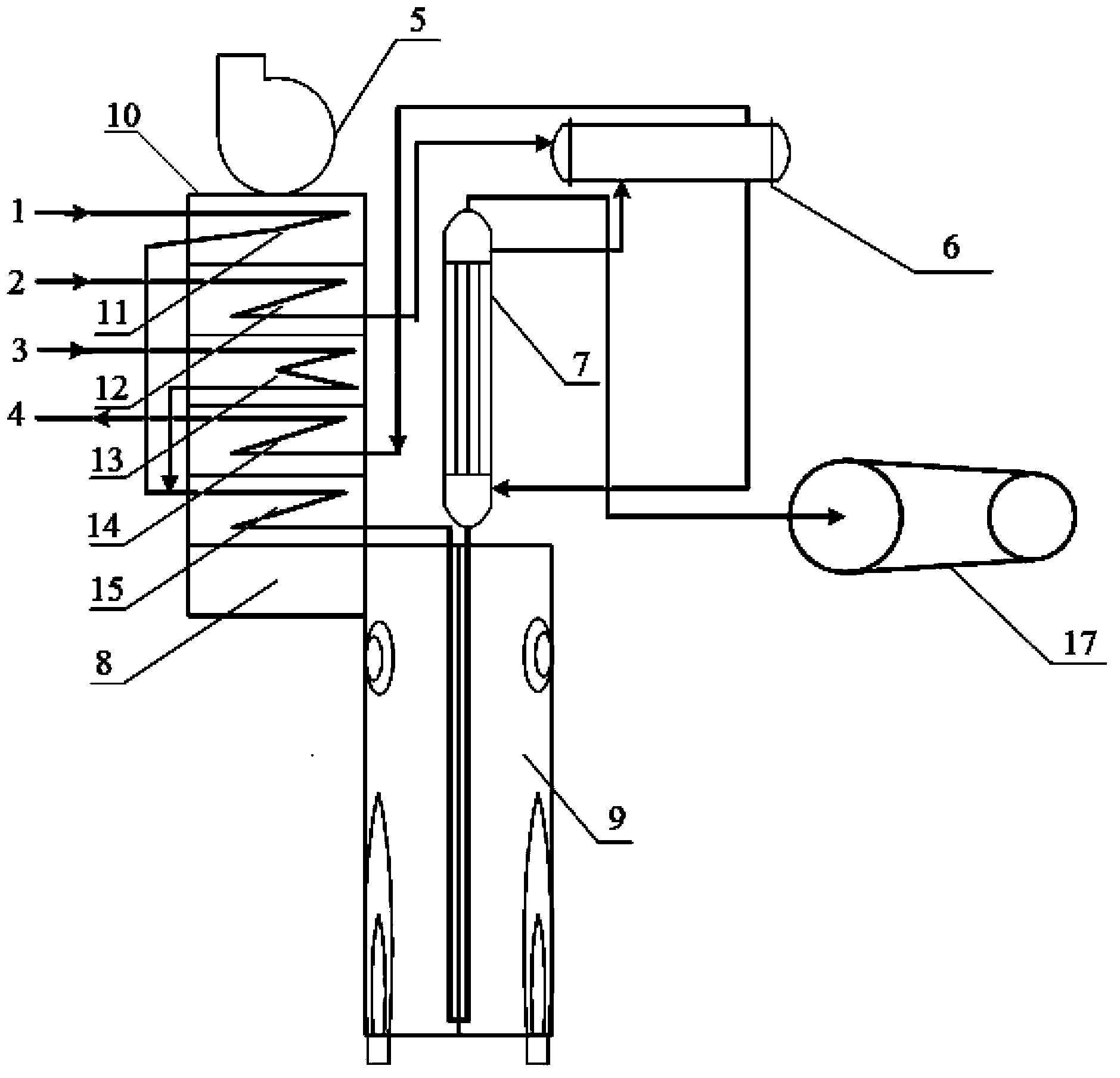

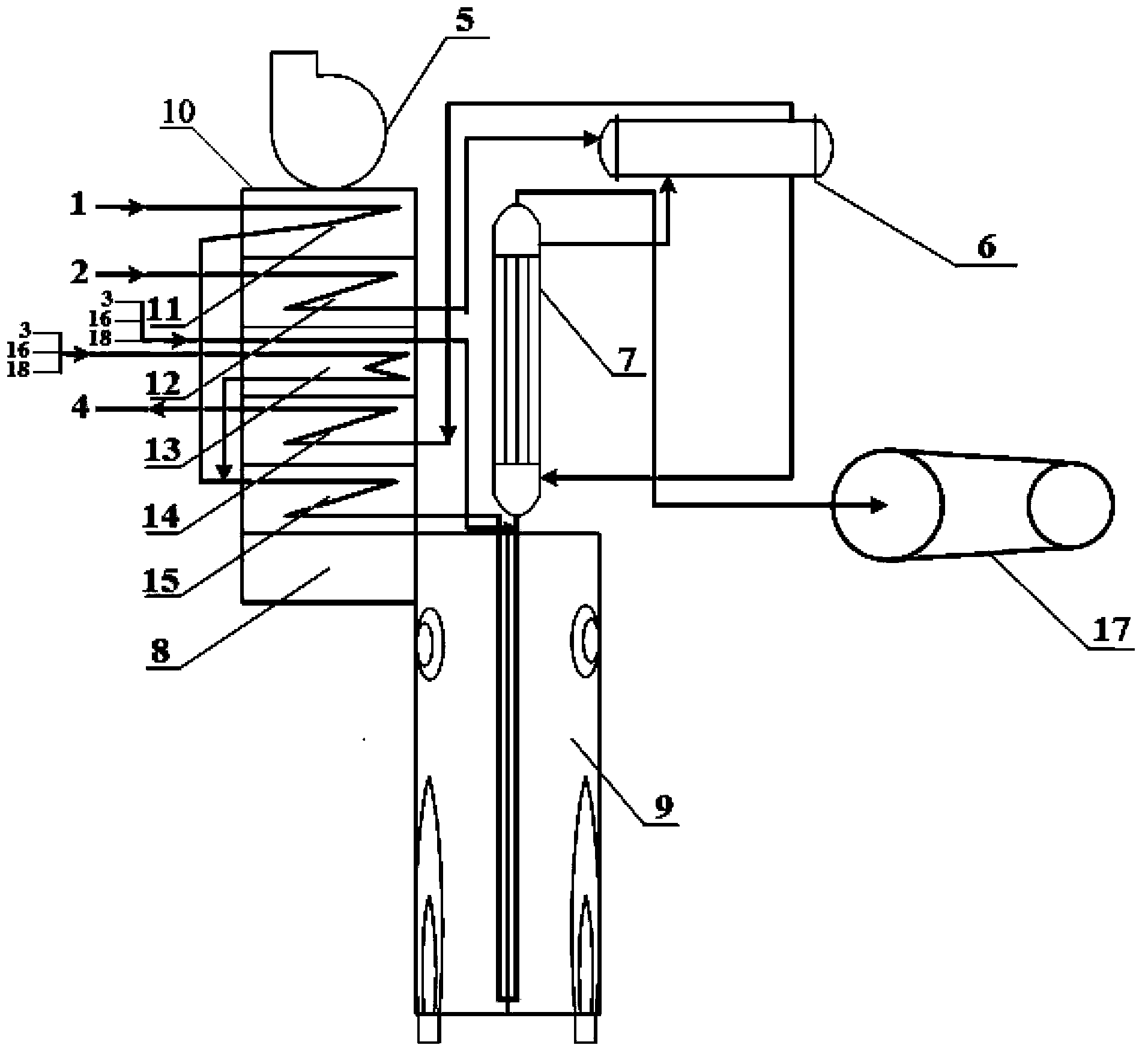

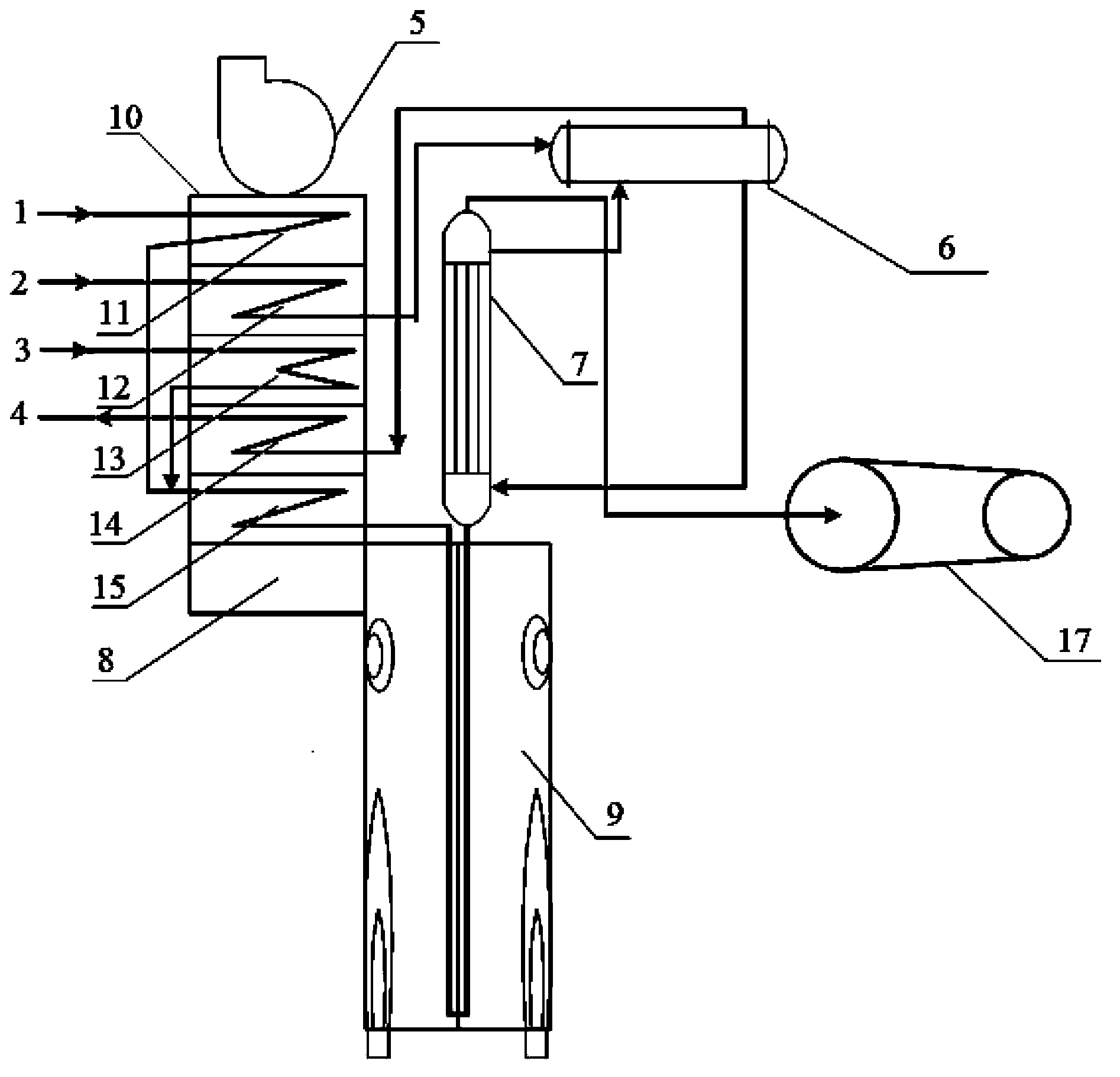

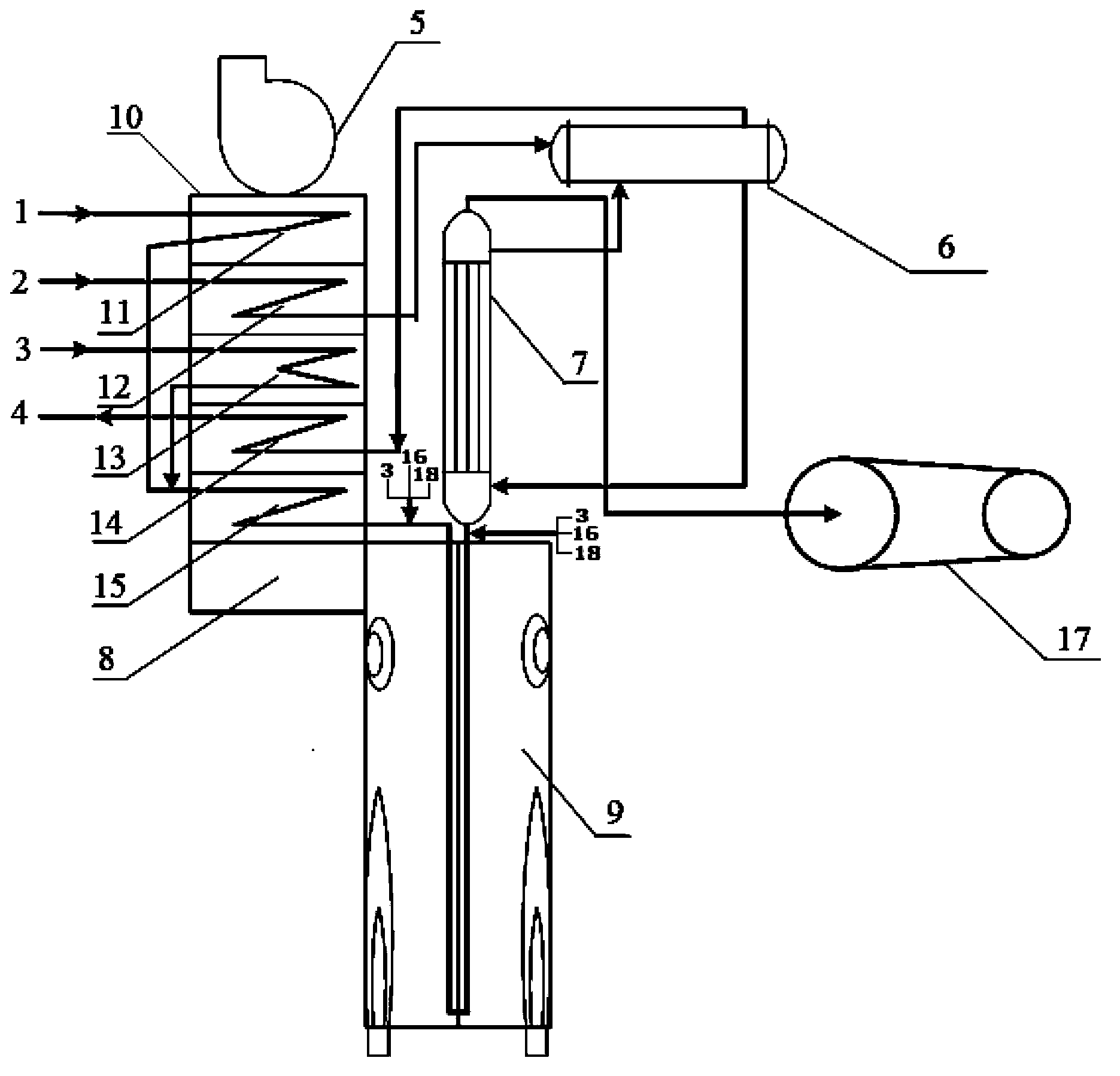

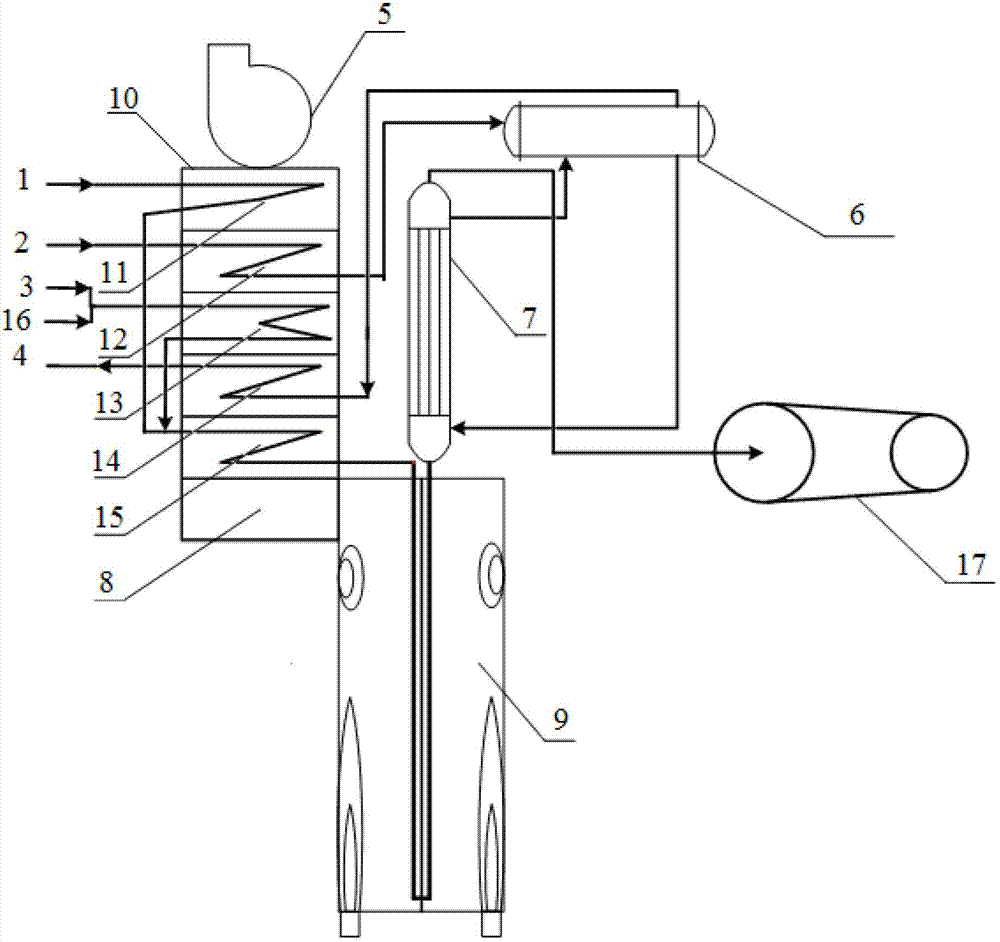

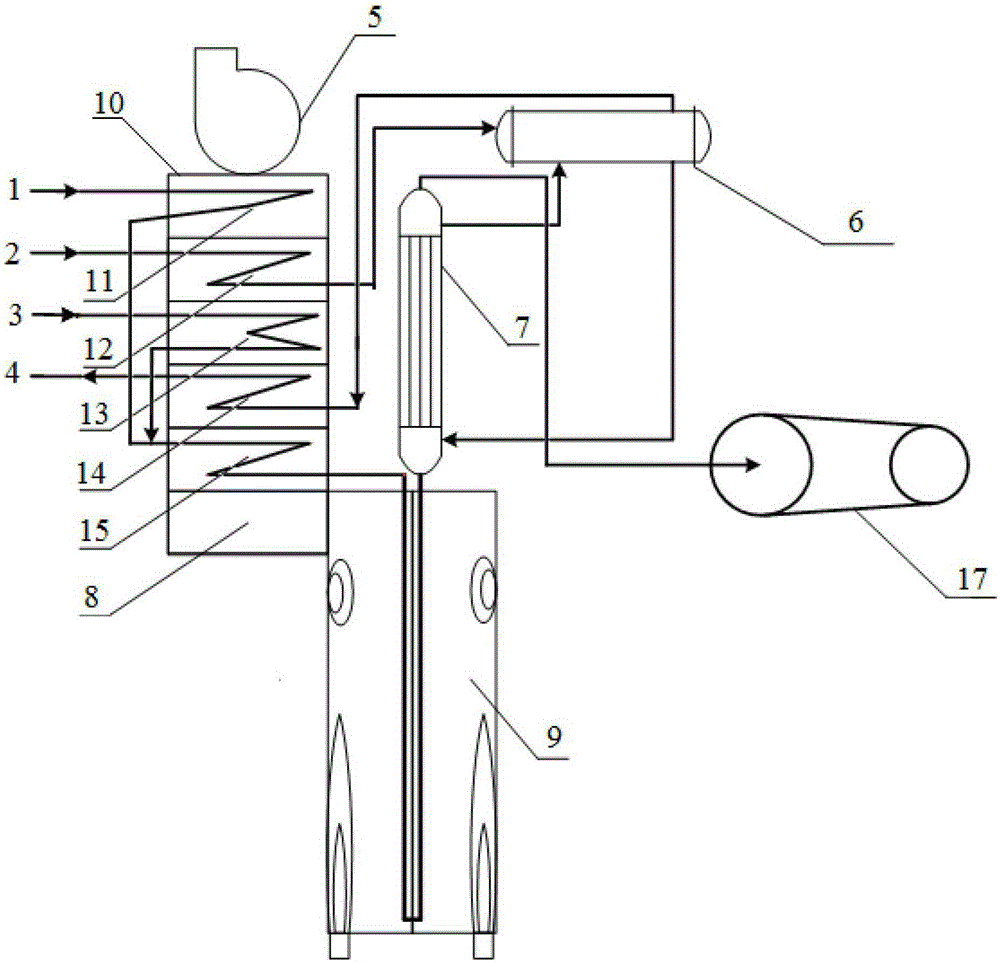

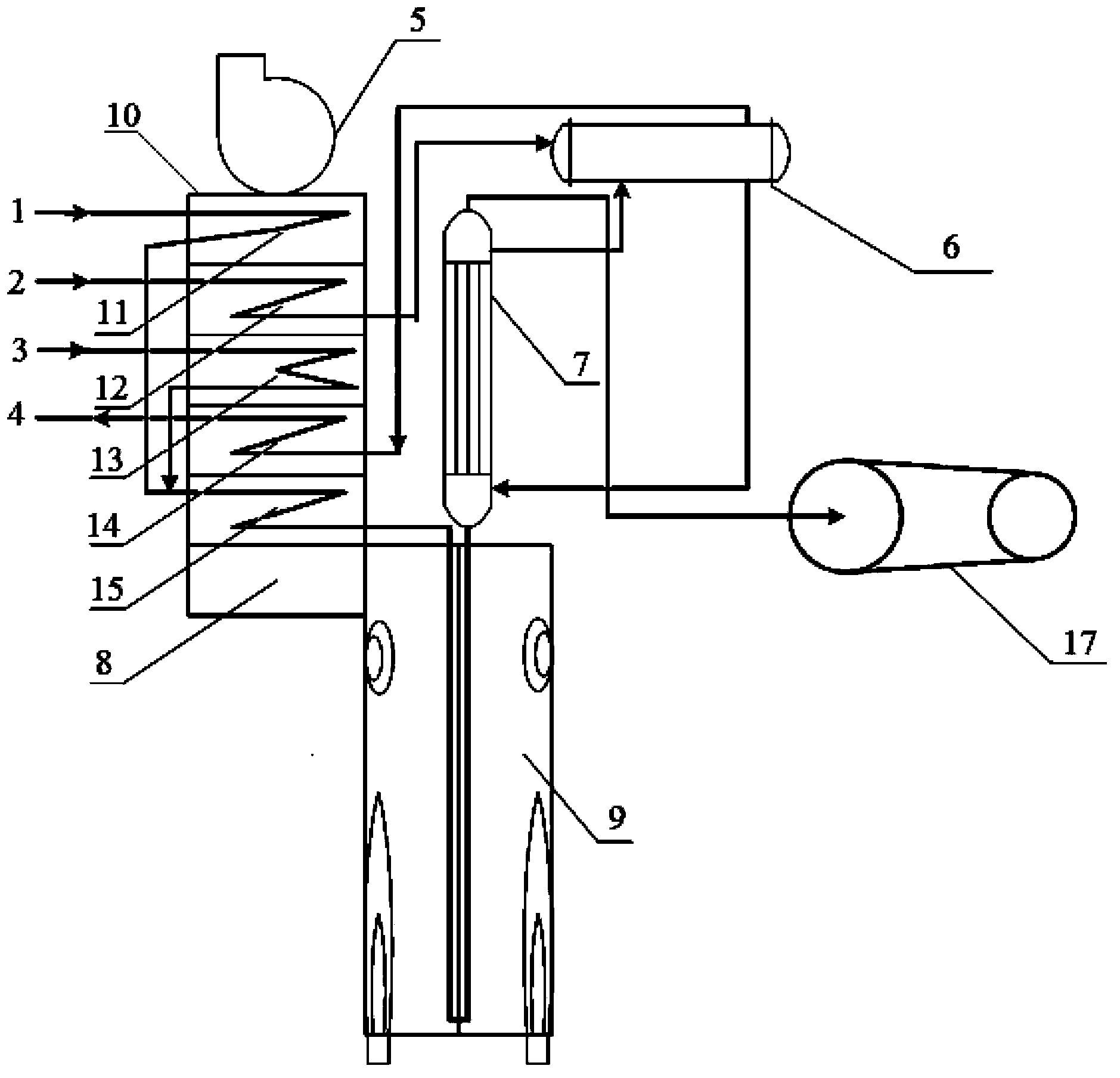

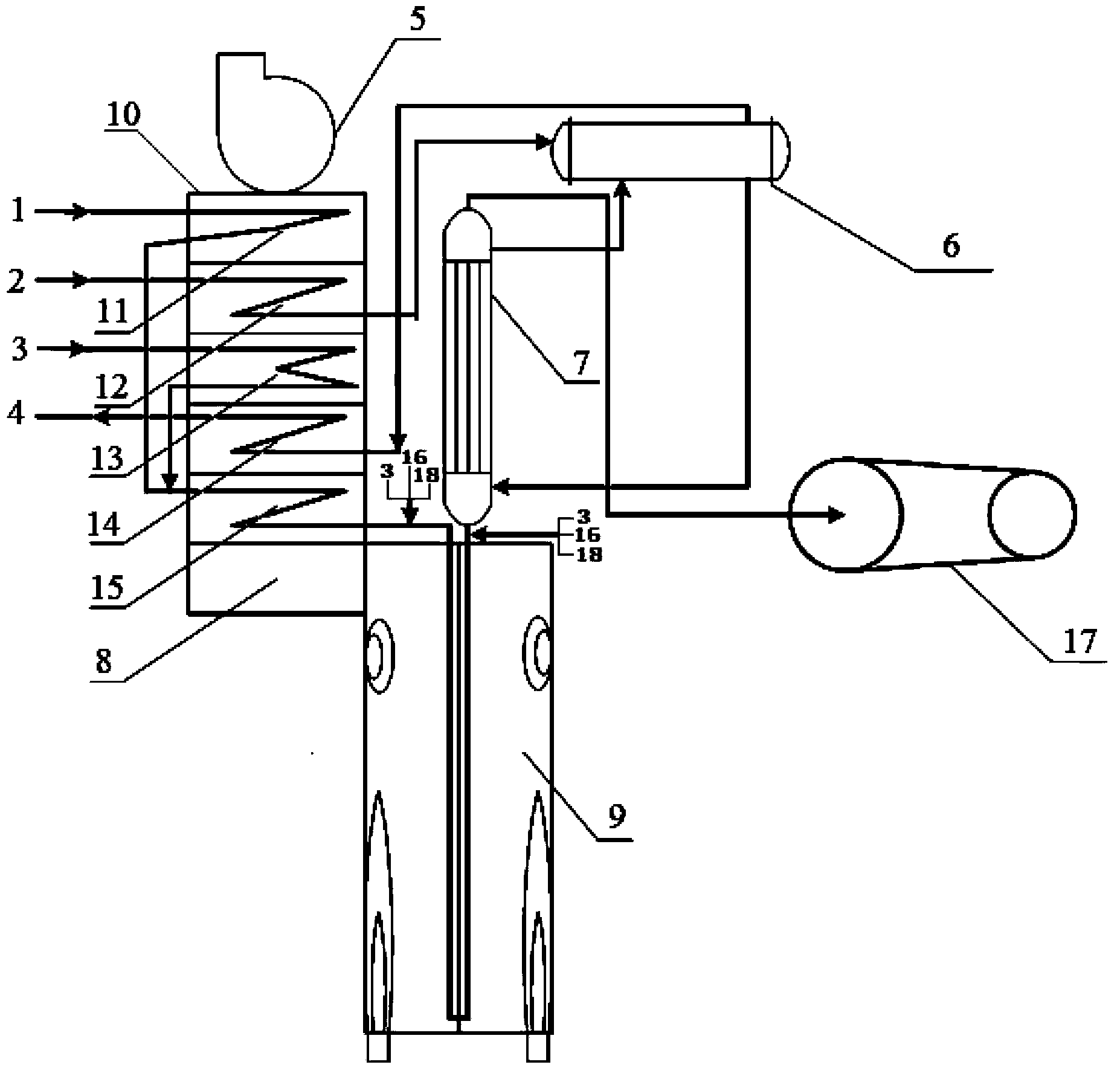

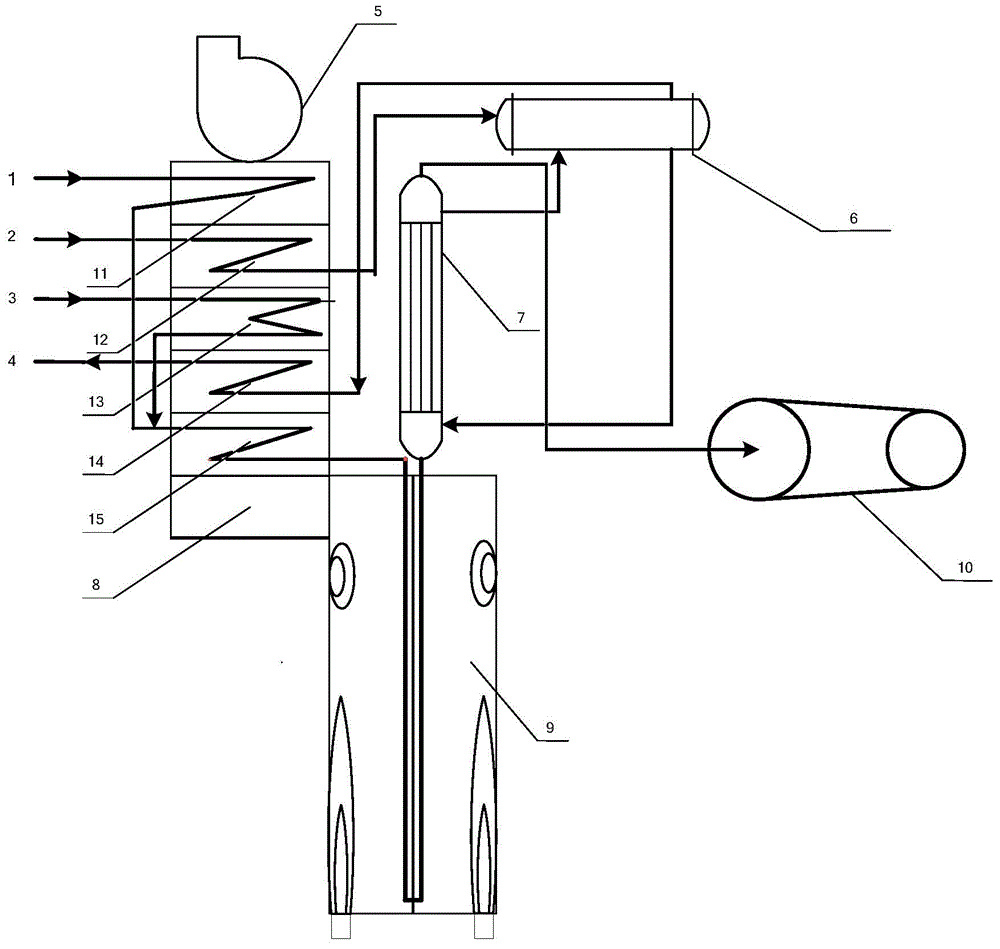

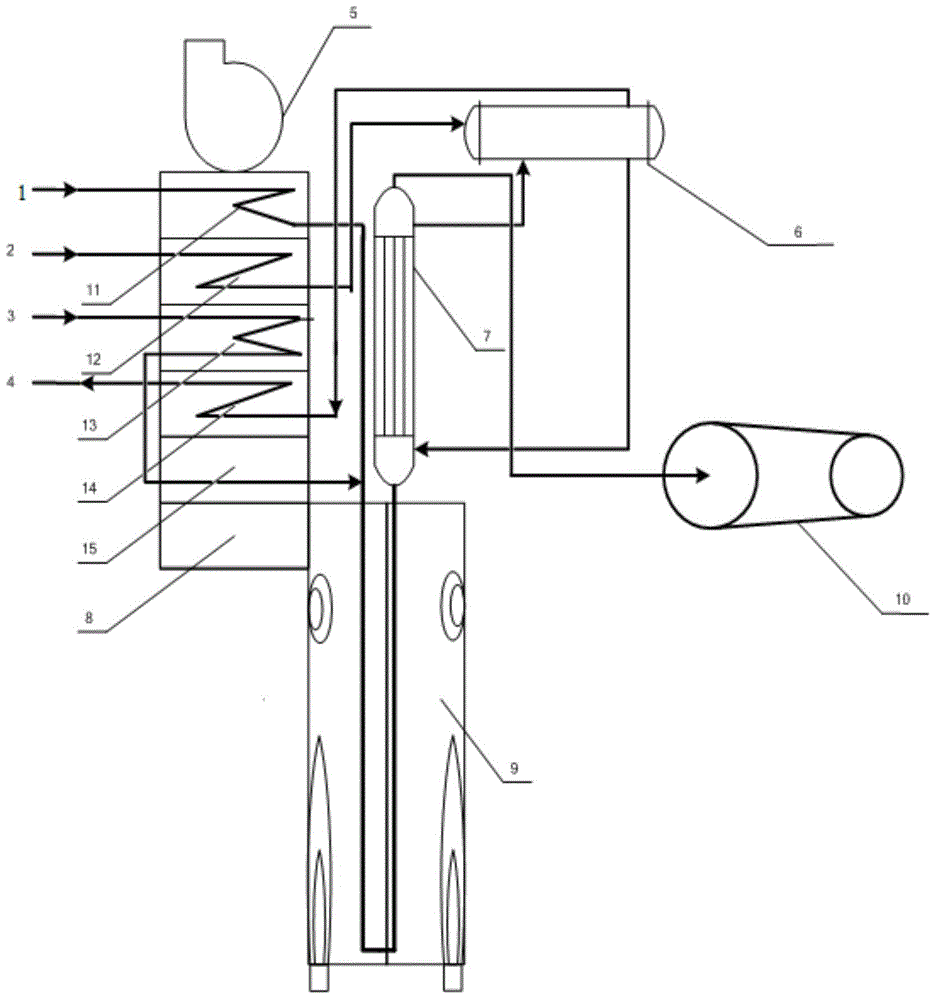

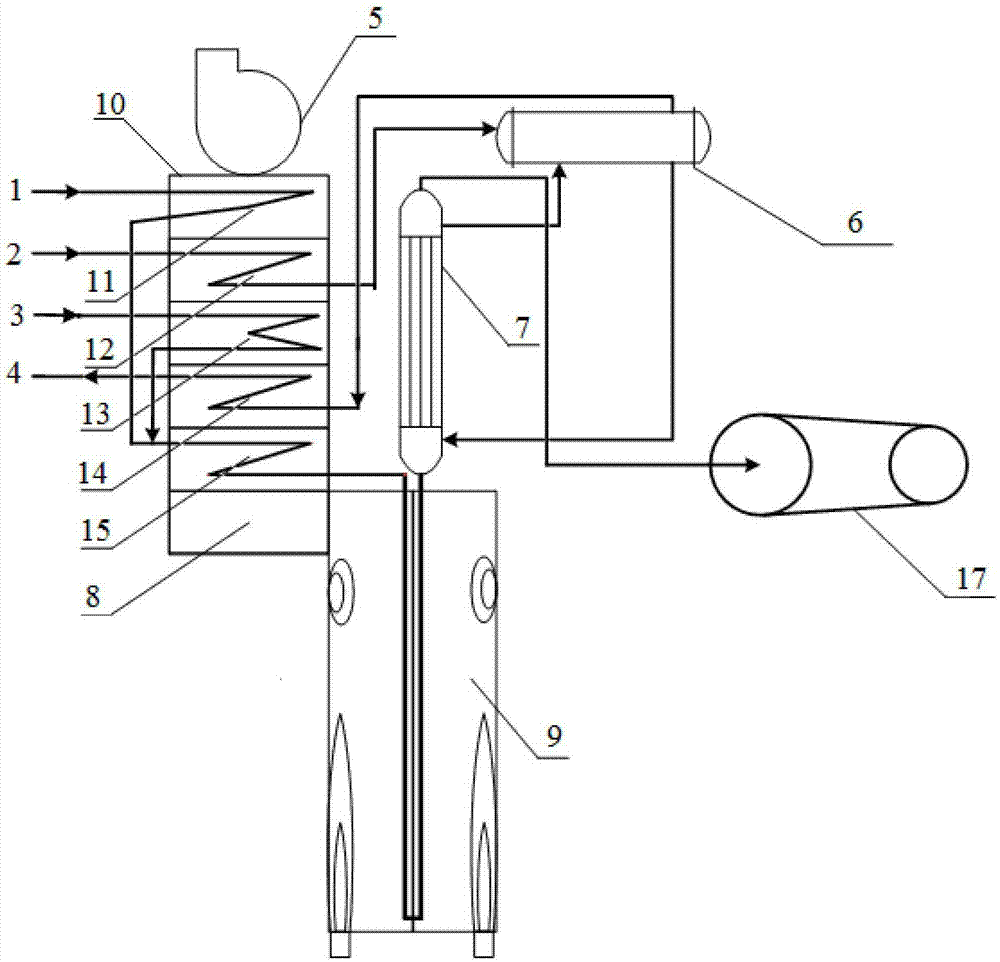

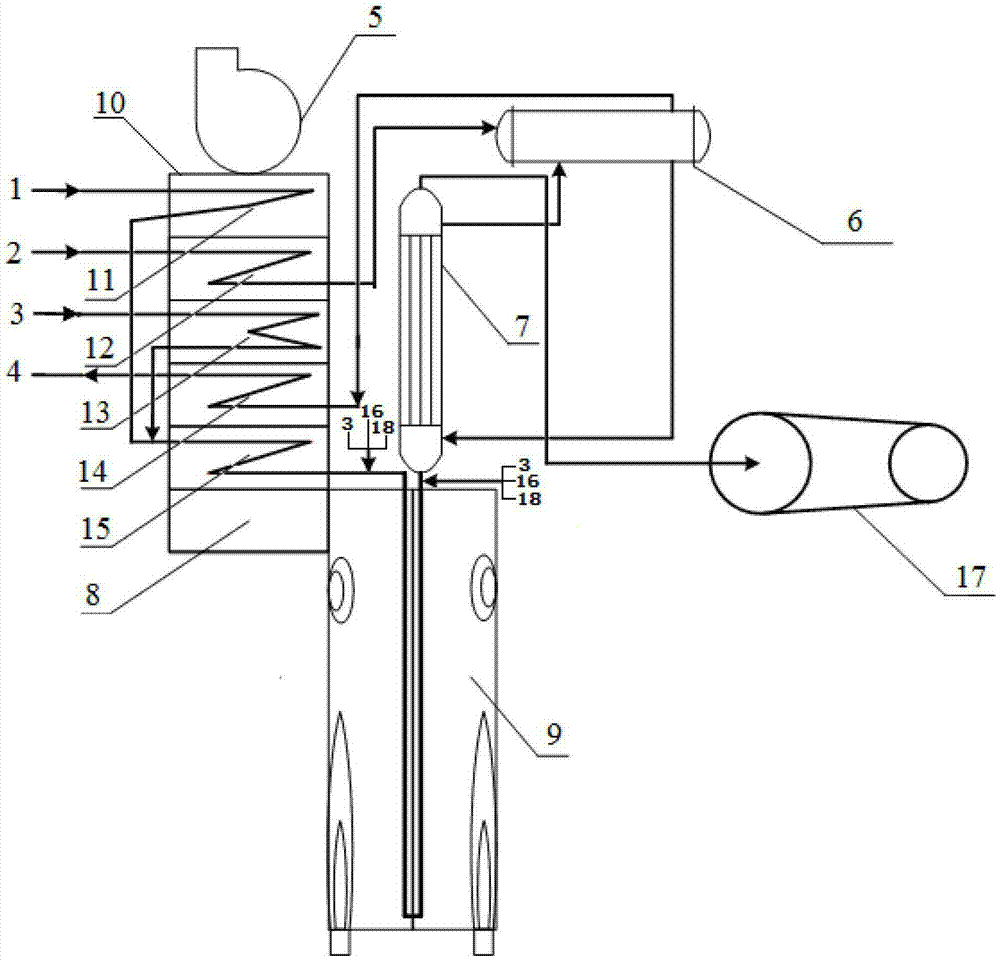

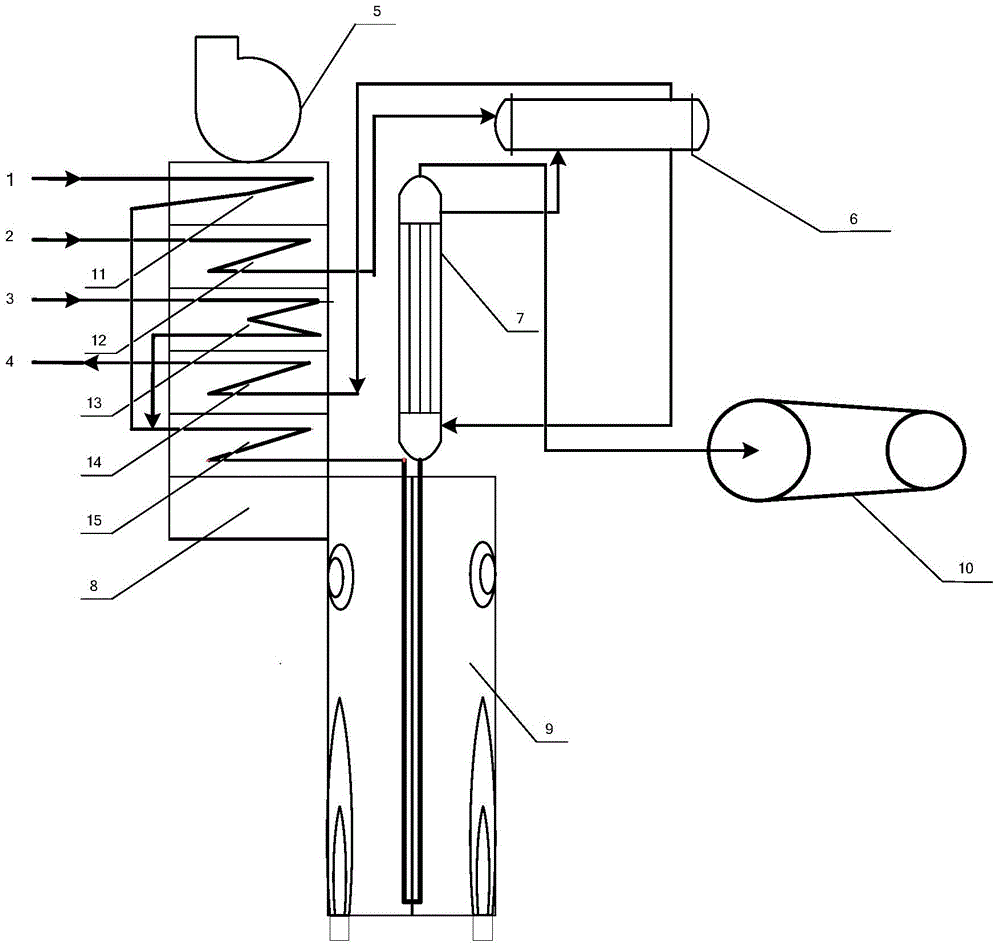

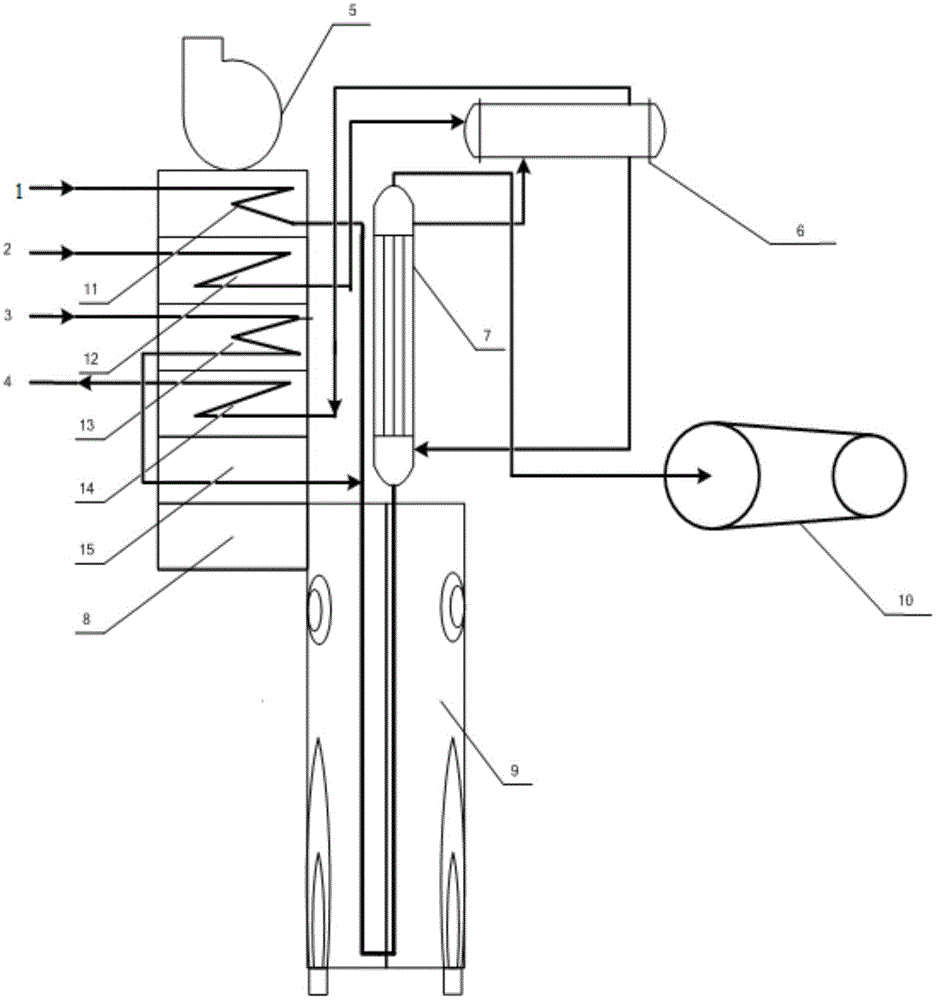

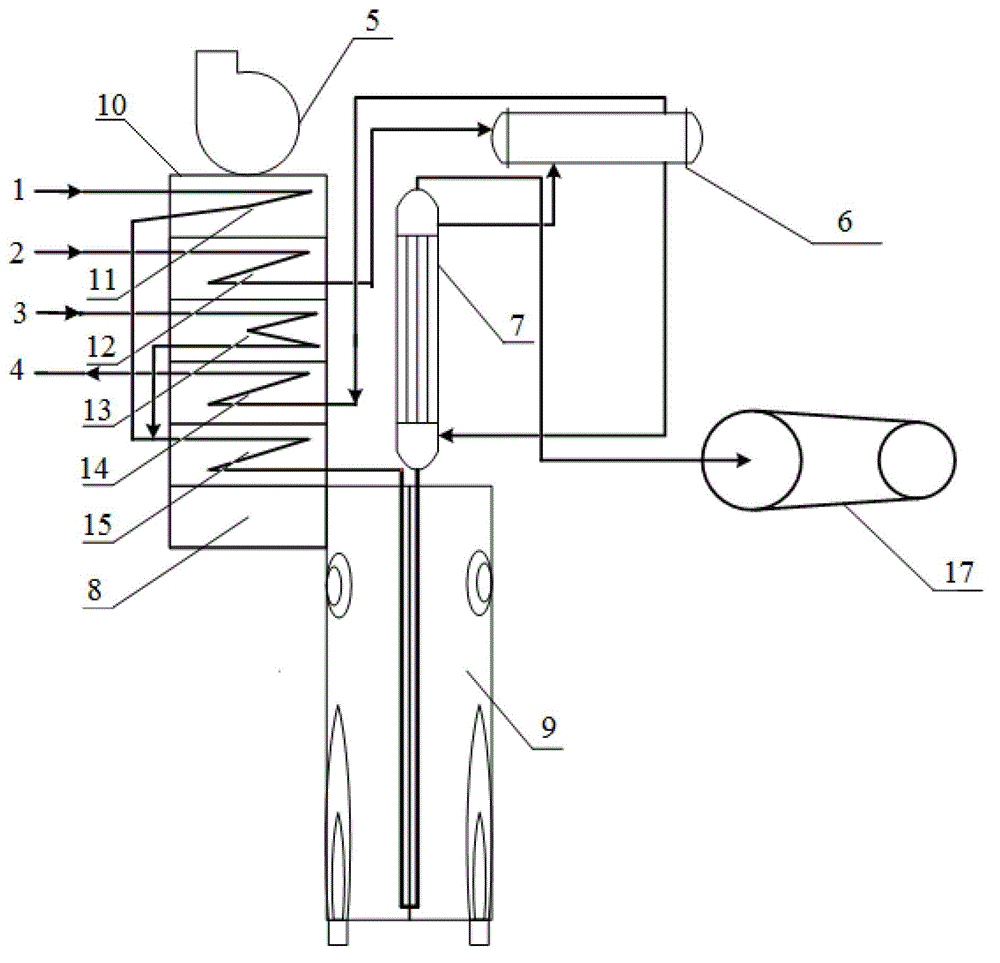

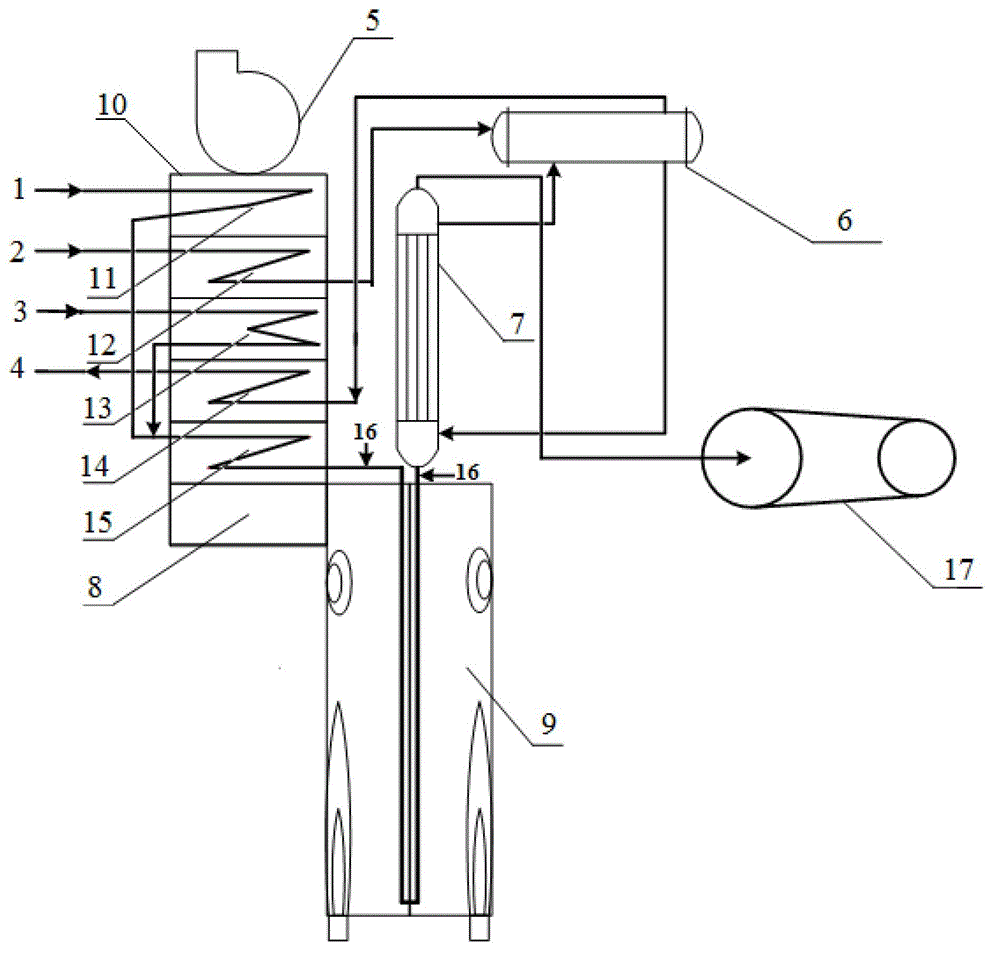

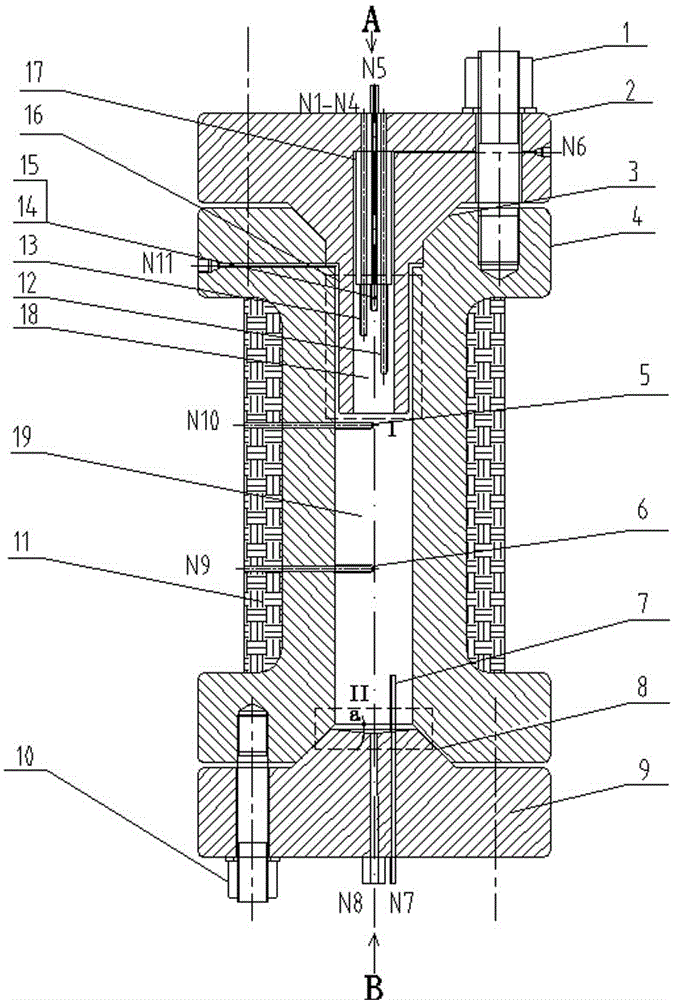

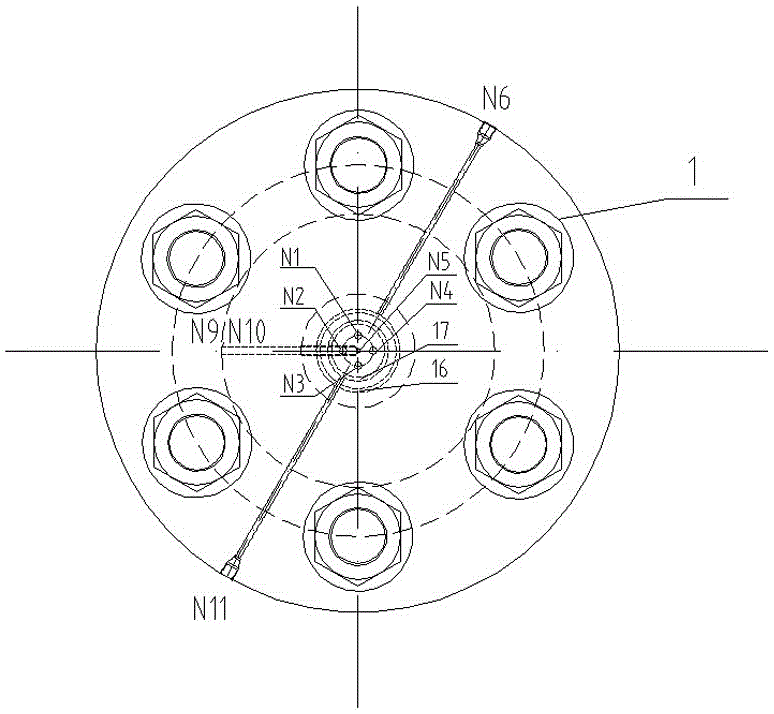

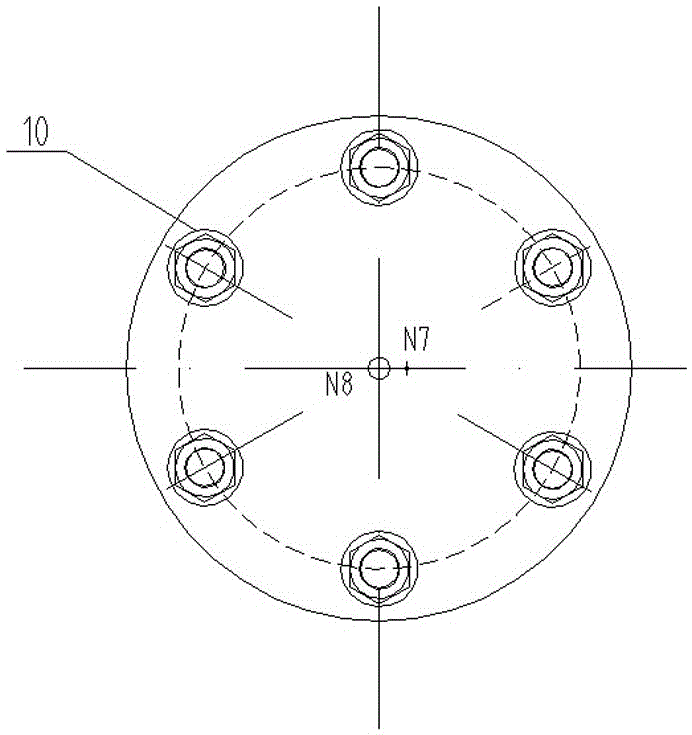

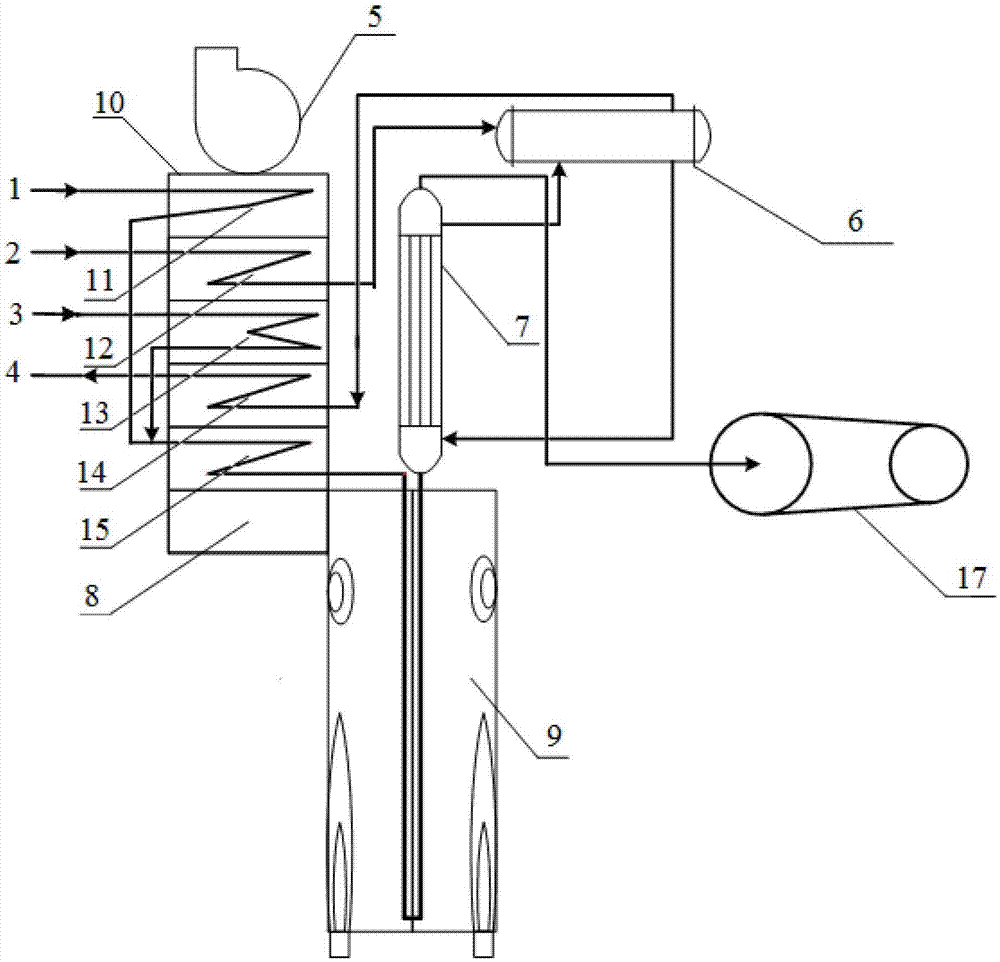

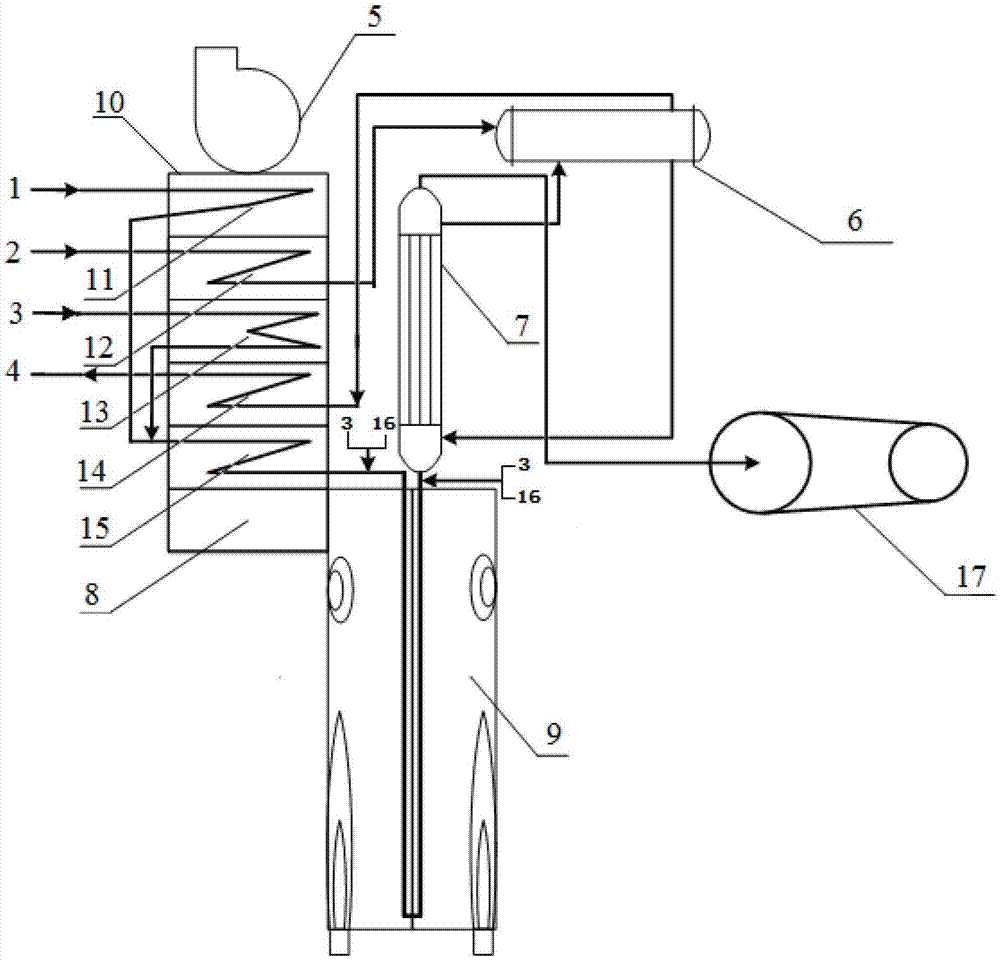

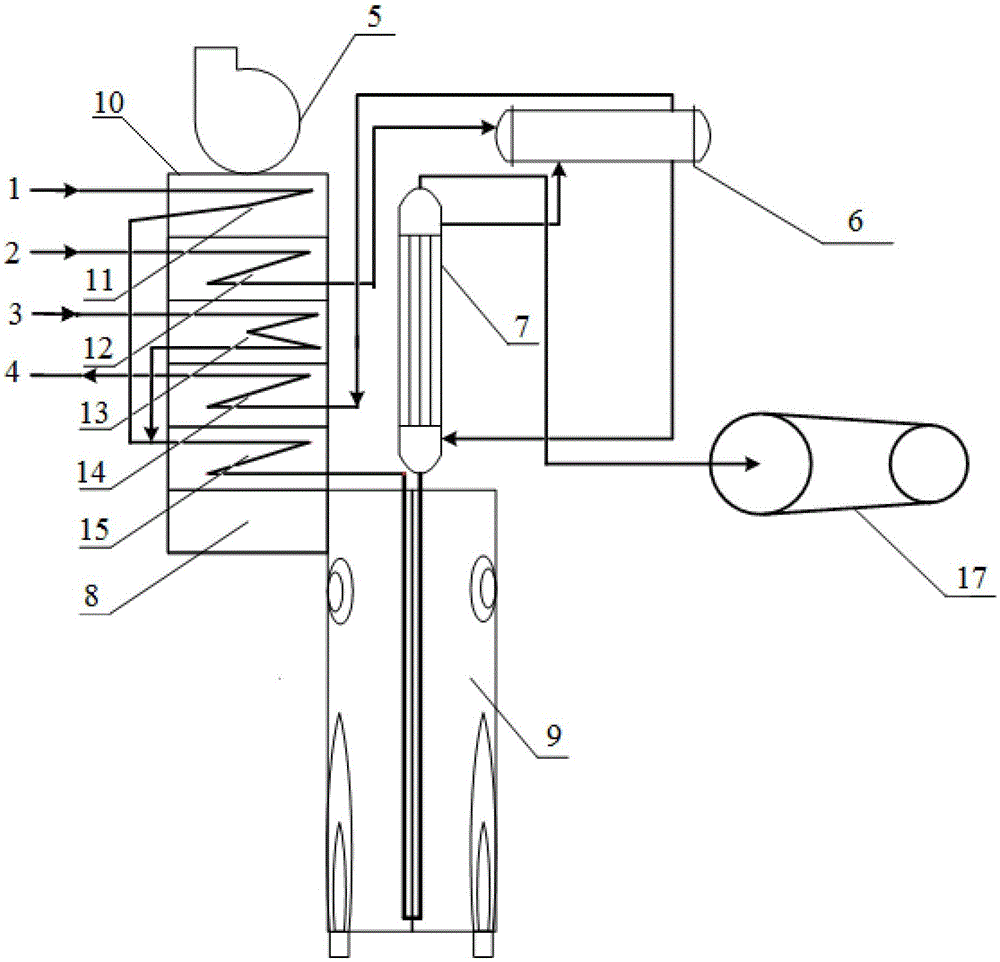

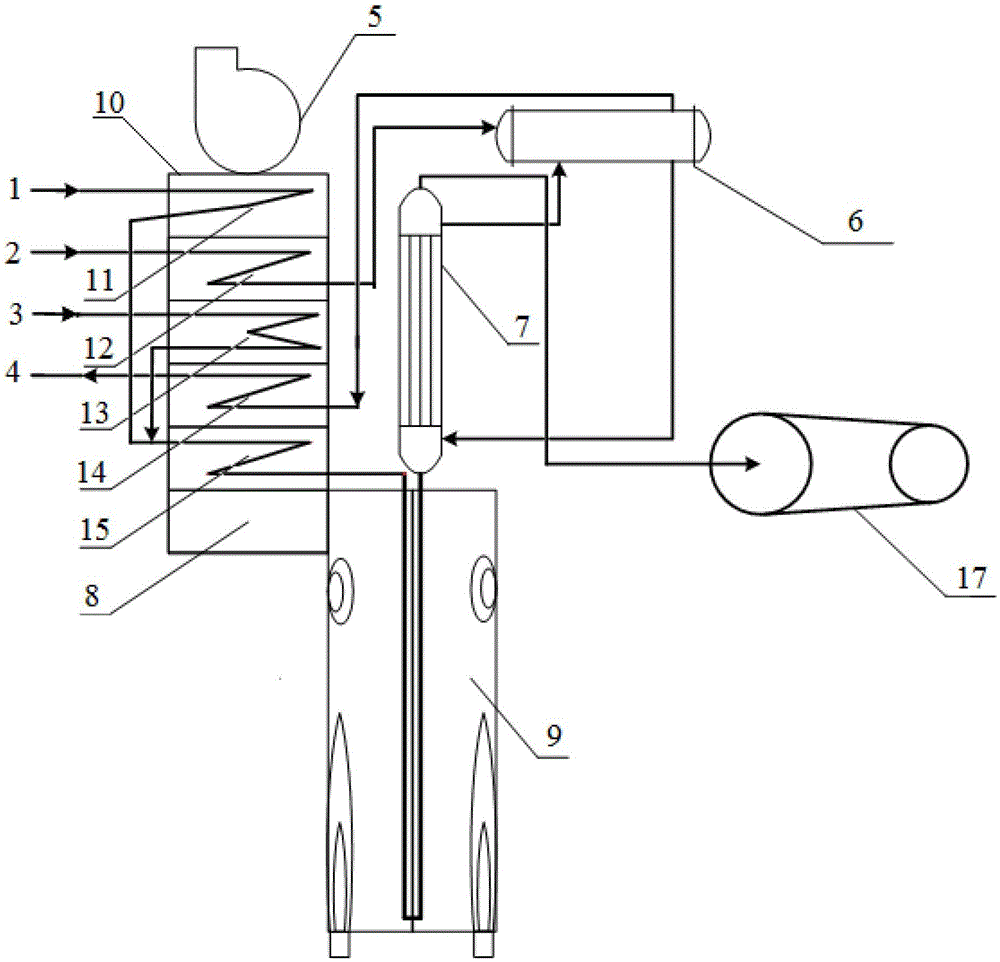

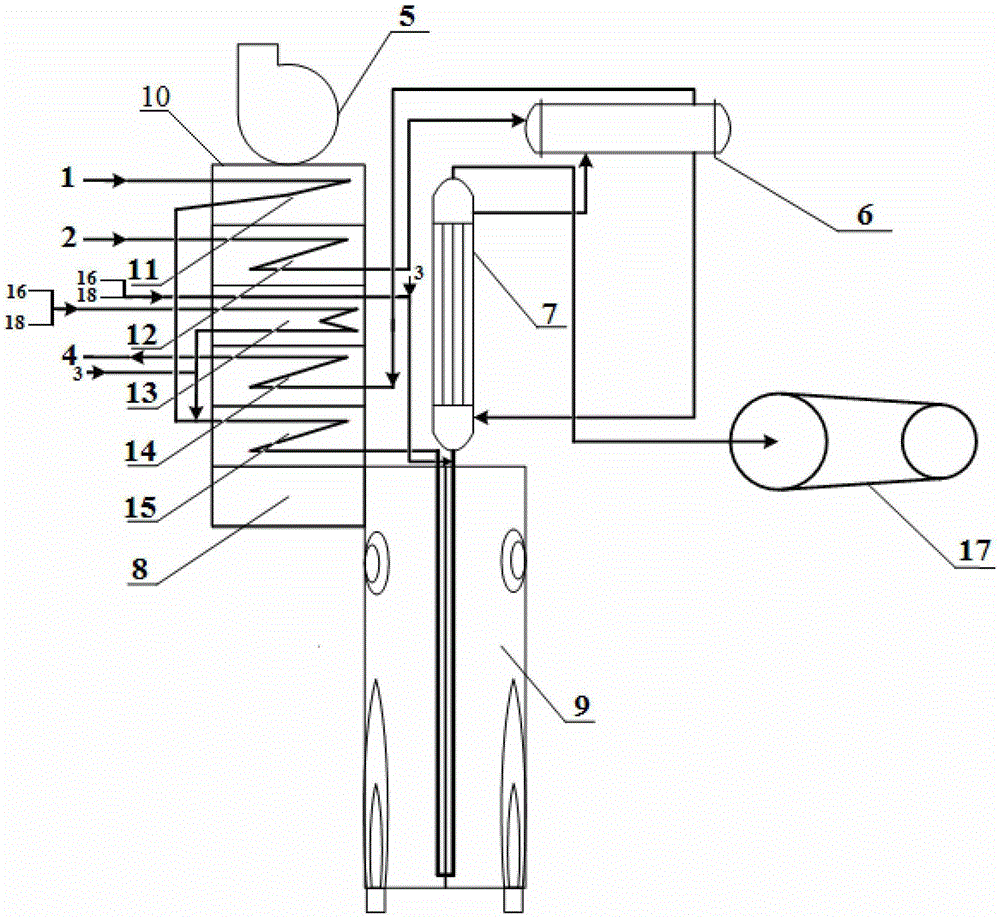

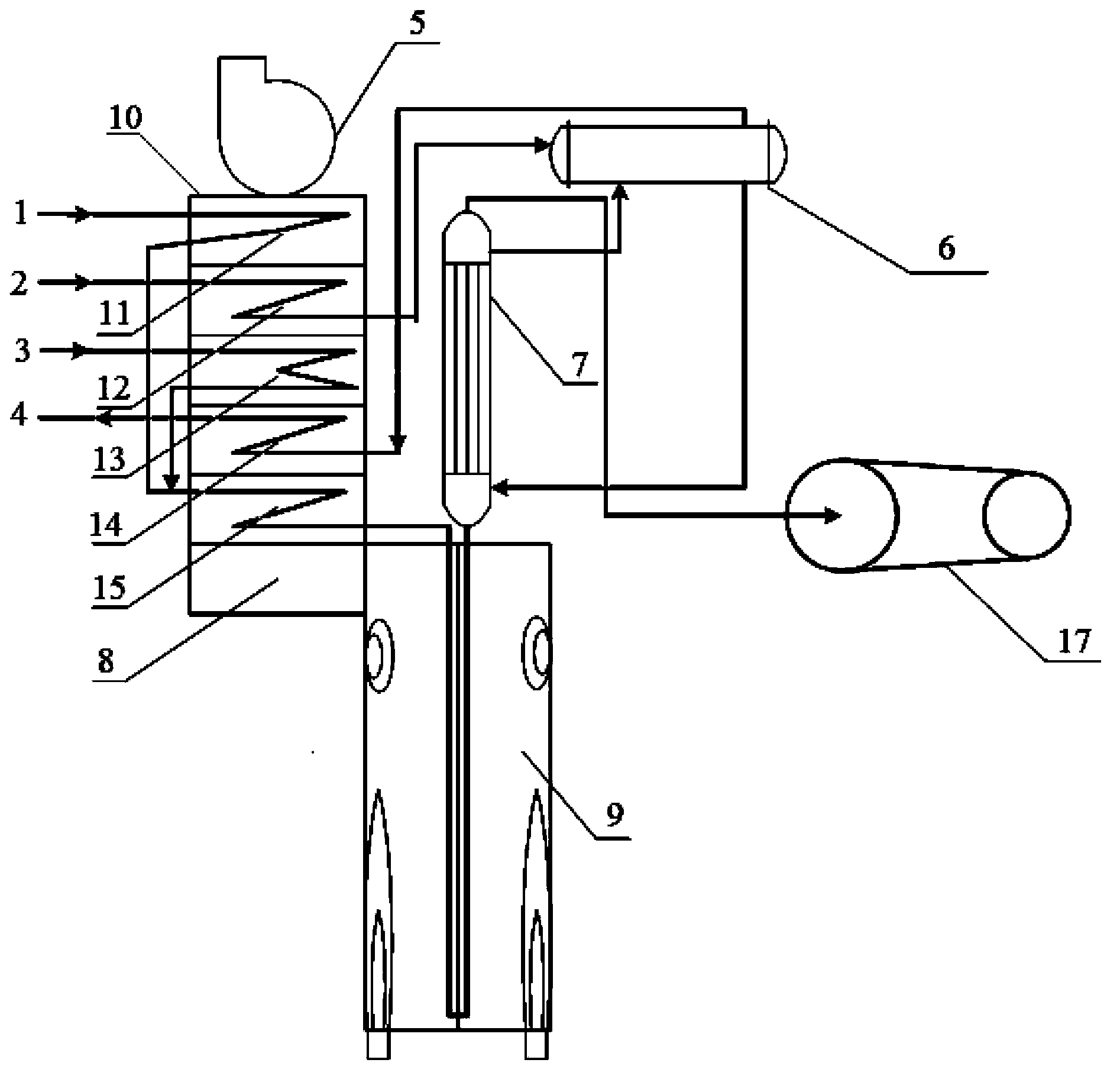

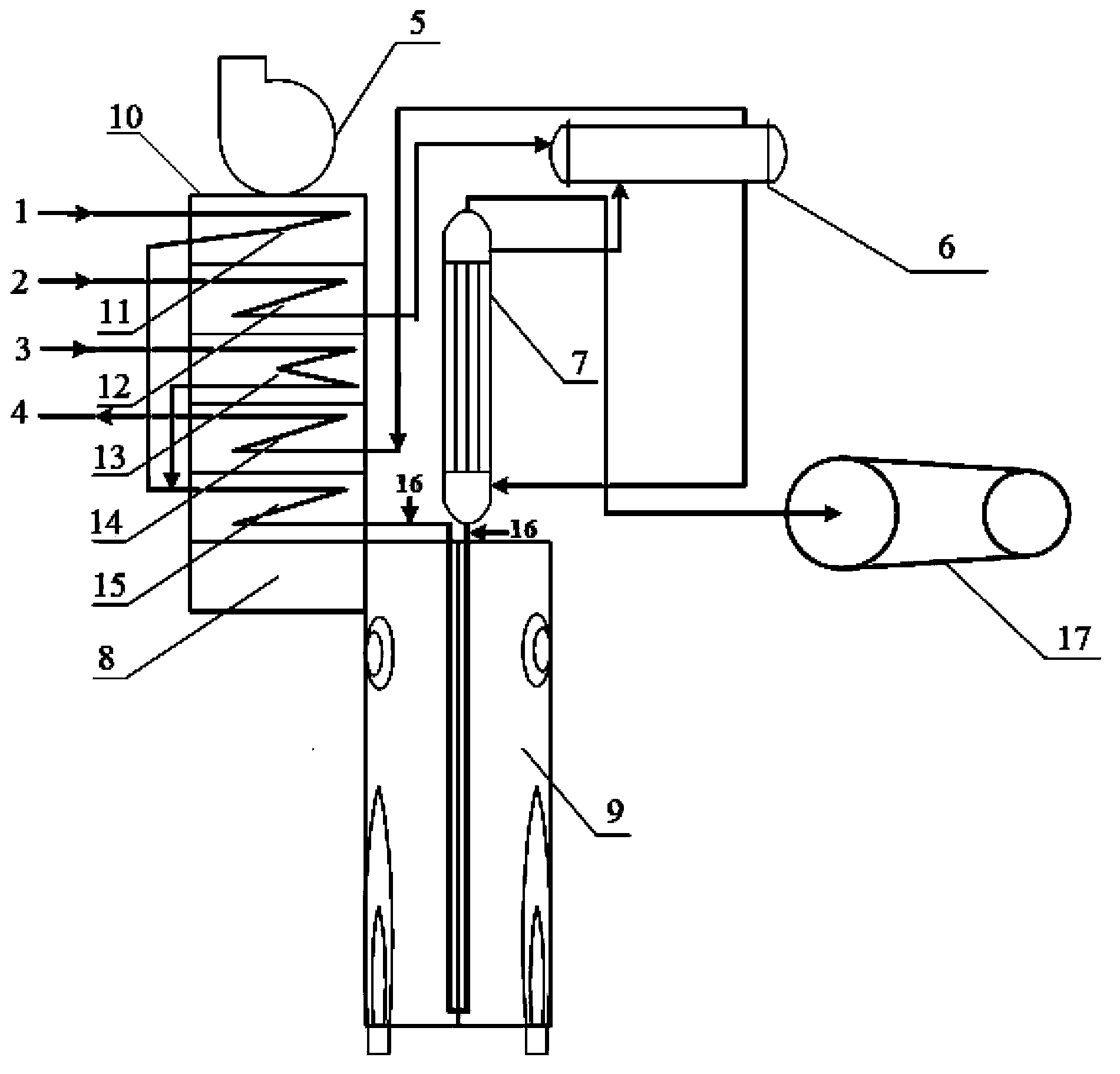

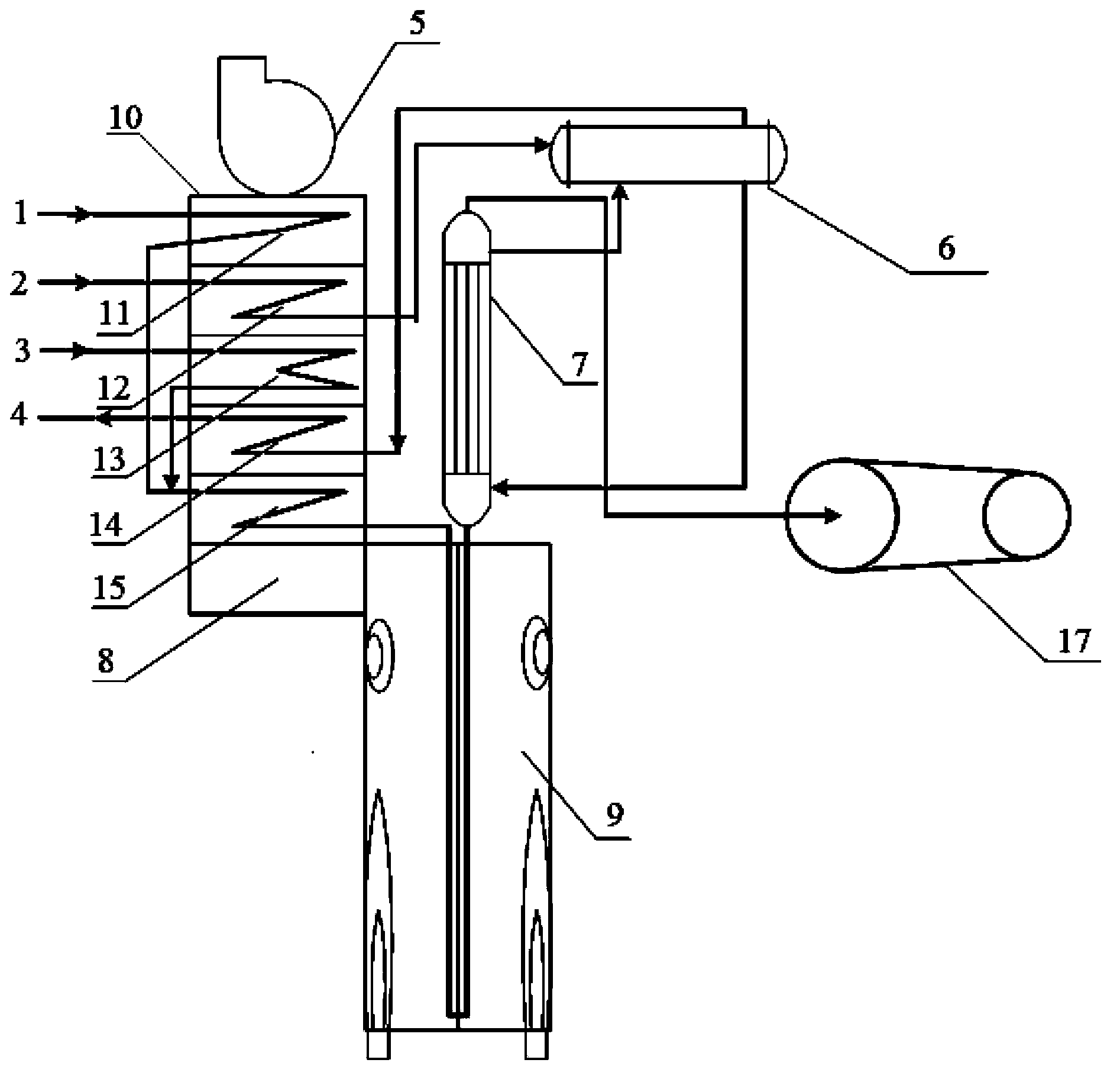

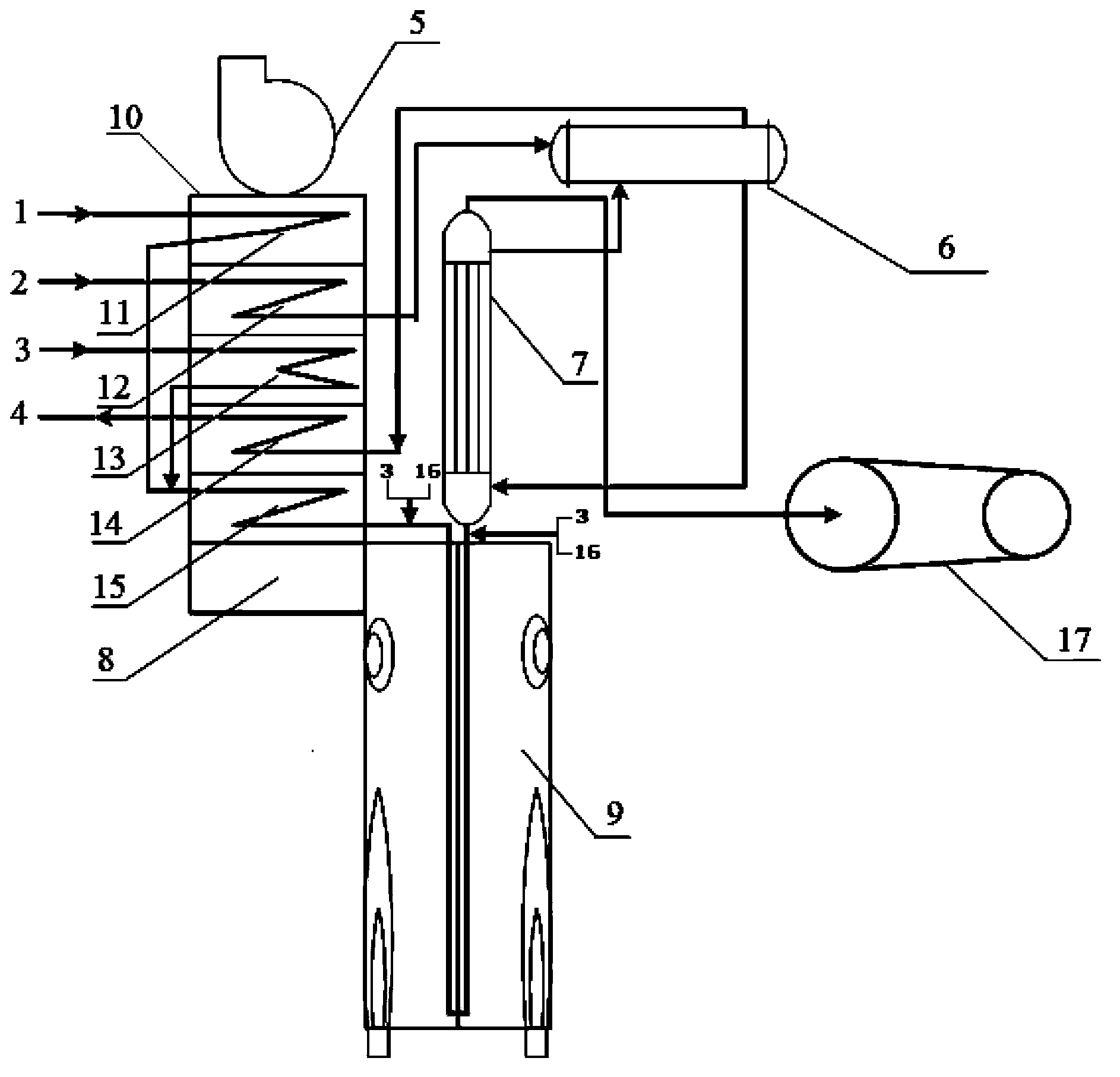

Supercritical water heat combustion reactor for thick oil injection production

InactiveCN103900094AStable combustionGood for burnoutFluid removalIncinerator apparatusCombustion chamberThermodynamics

The invention belongs to the field of energy and environments, and particularly relates to a supercritical water heat combustion reactor for thick oil injection production. The supercritical water heat combustion reactor for thick oil injection production comprises a reaction chamber, an upper top cover and a lower bottom cover, wherein the reaction chamber is hollow, openings are formed in the upper end and the lower end of the reaction chamber respectively, the upper top cover is connected with the opening formed in the upper end of the reaction chamber in a sealed mode, the lower bottom cover is connected with the opening formed in the lower end of the reaction chamber, and a closed space is formed by the reaction chamber, the upper top cover and the lower bottom cover; a cylindrical stepped hollow portion is formed in the center of the upper top cover, a stepped hollow portion on the lower portion of the cylindrical stepped hollow portion serves as a combustor, a stepped hollow portion on the upper portion of the cylindrical stepped hollow portion serves as a communicated fuel inlet, an annular groove is formed in the outer side of the lower end of the stepped hollow portion on the upper portion of the cylindrical stepped hollow portion, the lower portion of the annular groove is communicated with the combustor, and the annular groove is communicated with an oxidizing agent inlet formed in the side face of the upper top cover; a mixing chamber is arranged at the bottom of the combustor, an annular gap formed between the upper top cover and the reaction chamber is formed in the side of the combustor, and the annular gap is communicated with a supplementary water inlet formed in the side face of the reaction chamber.

Owner:TAIYUAN UNIV OF TECH

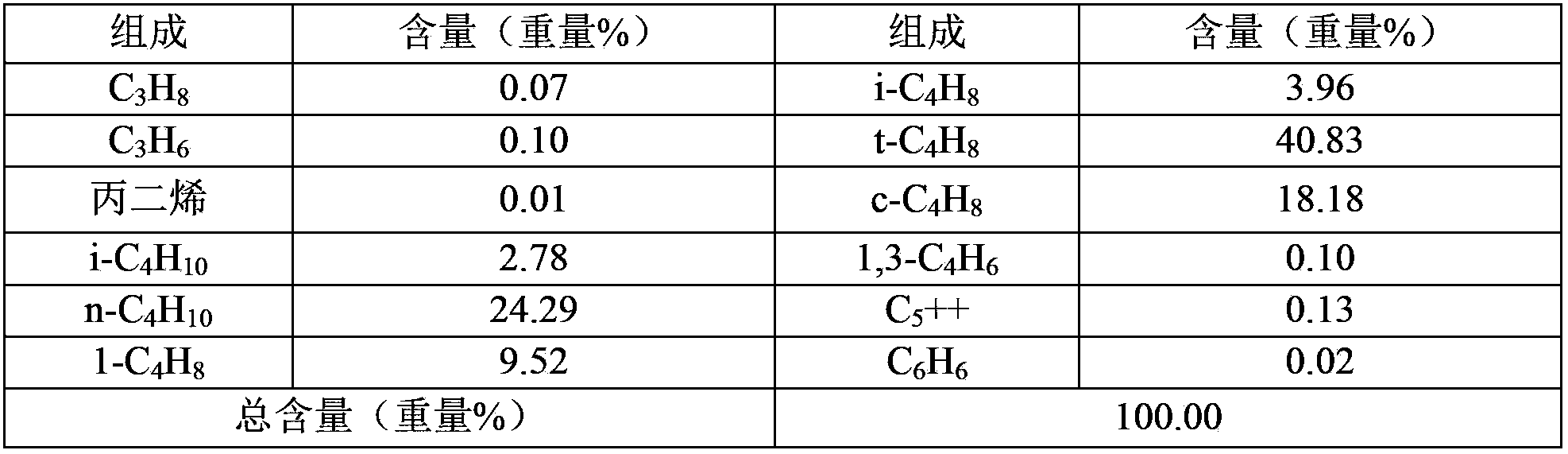

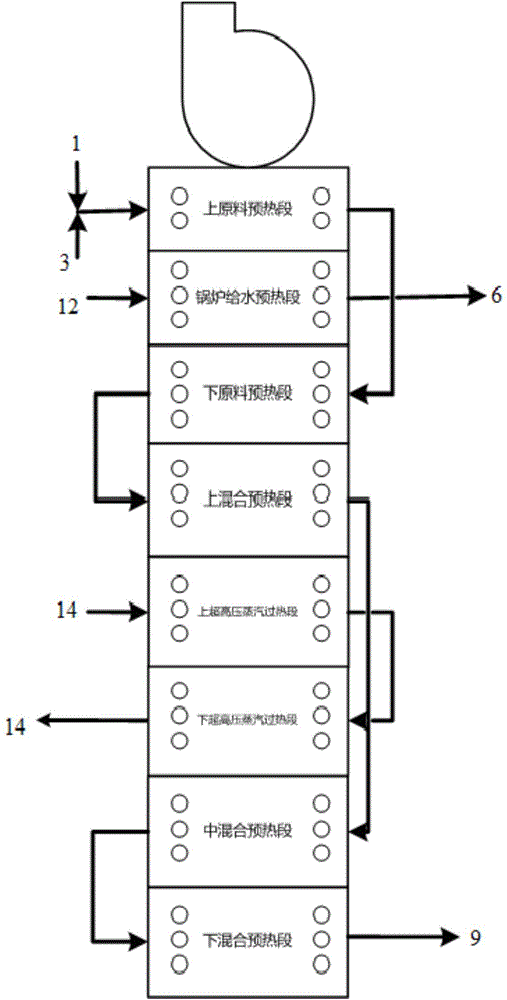

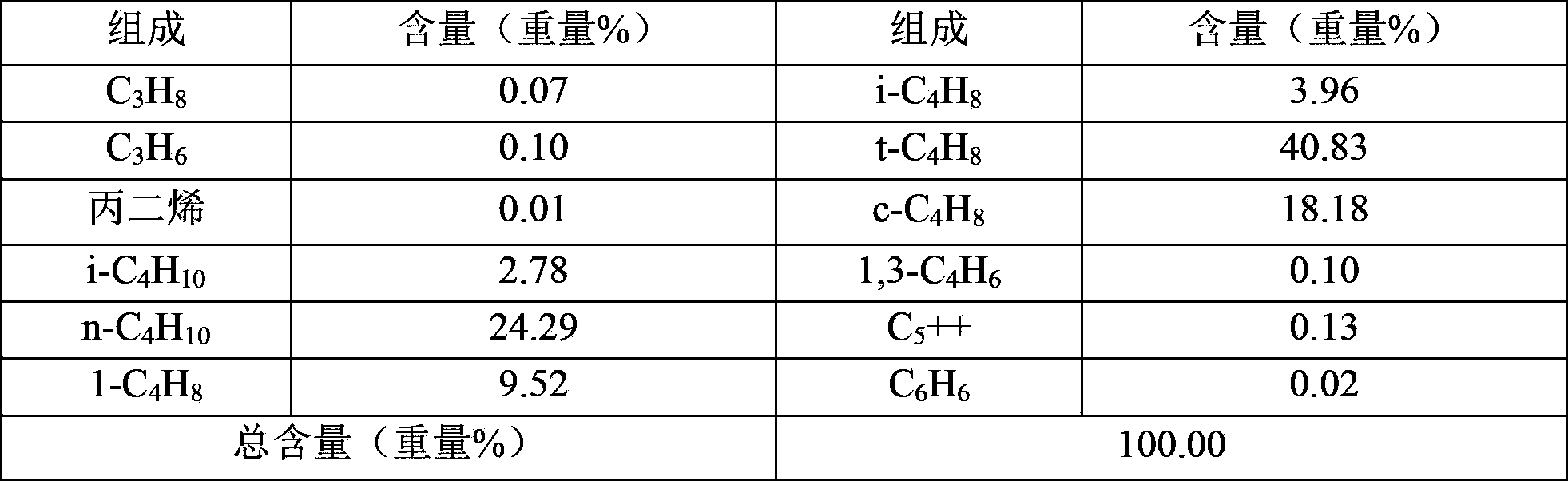

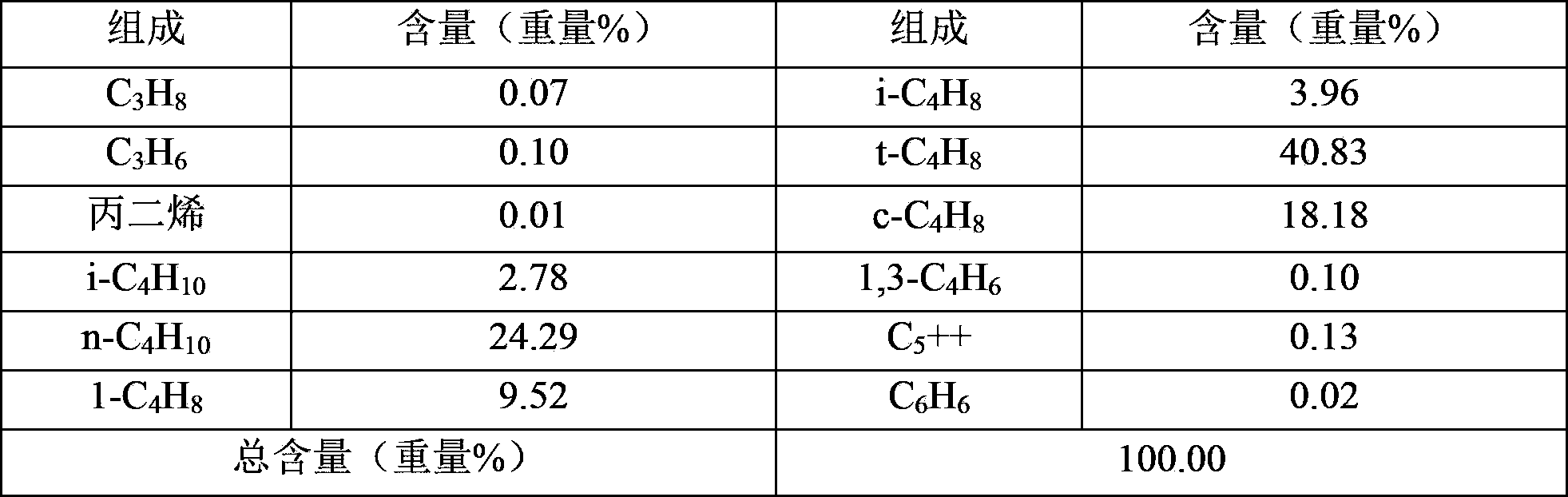

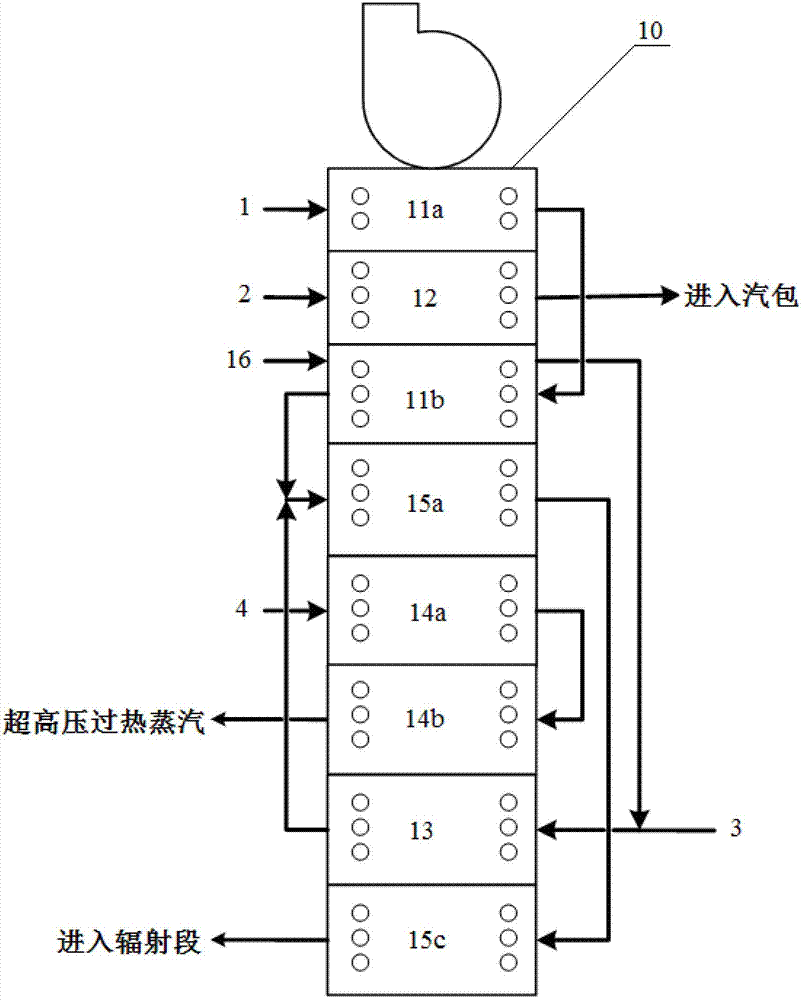

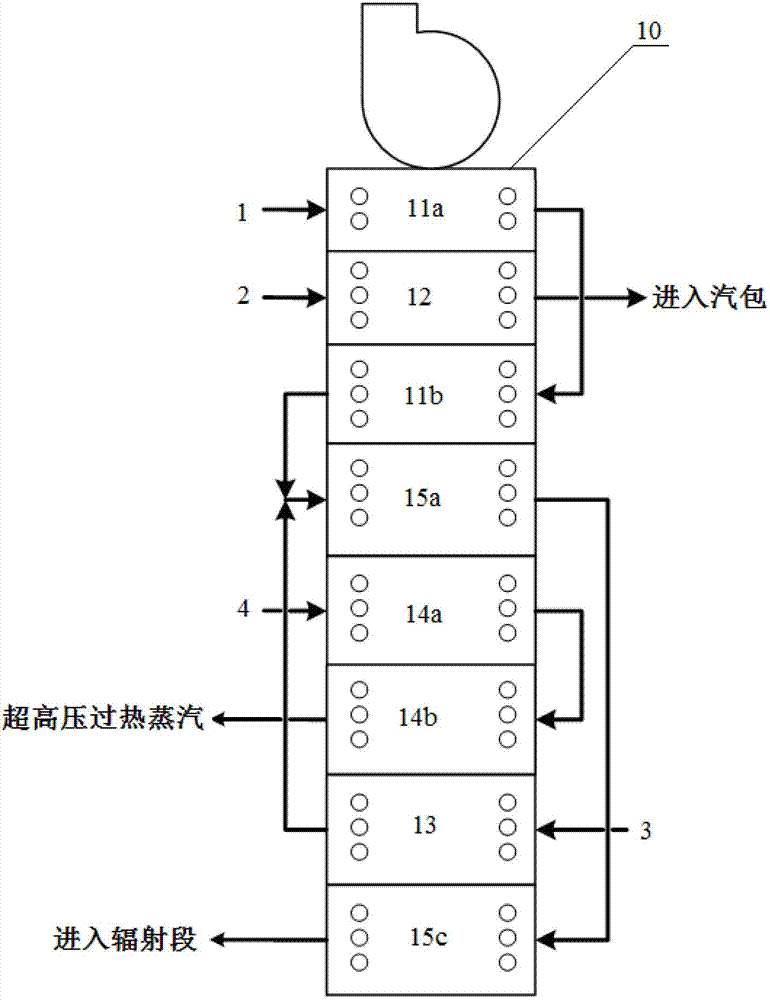

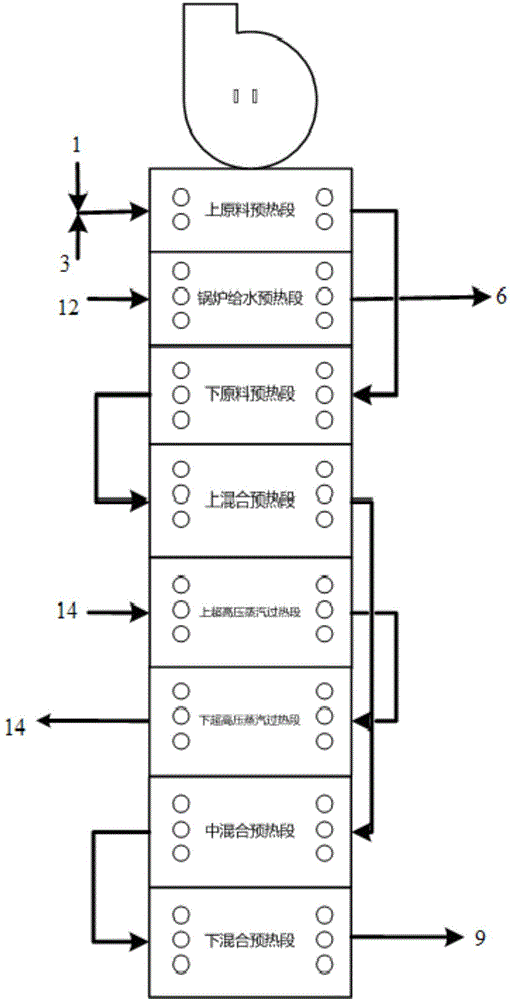

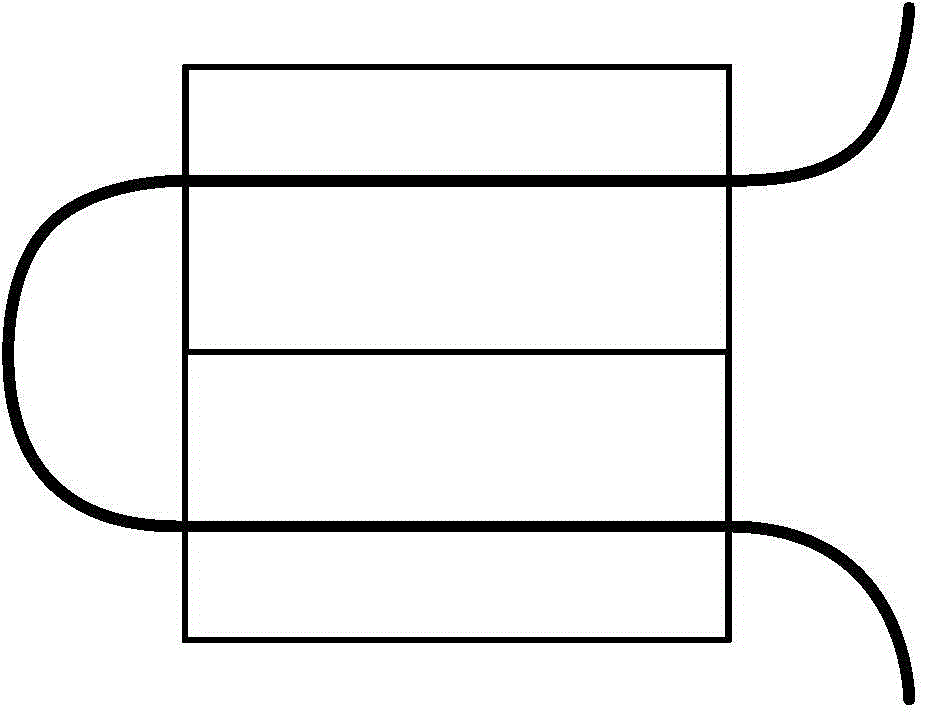

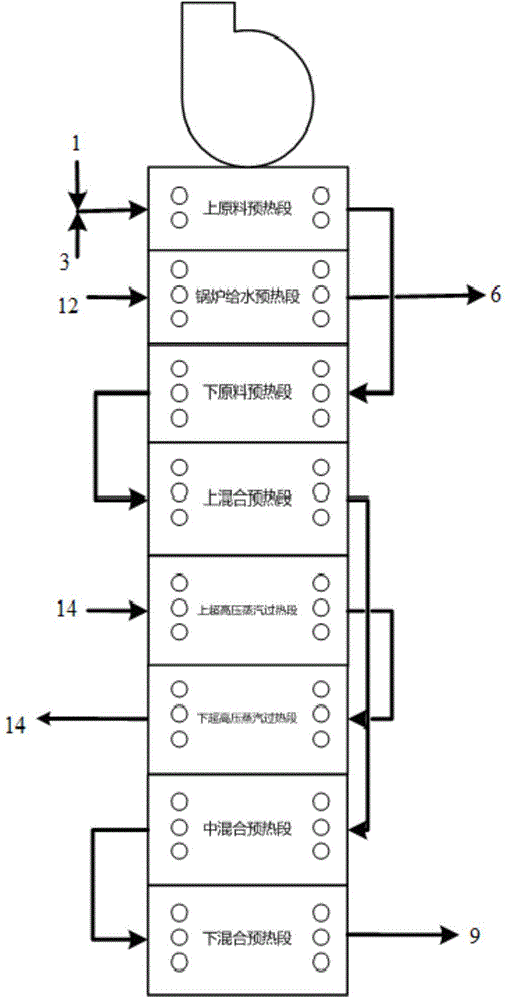

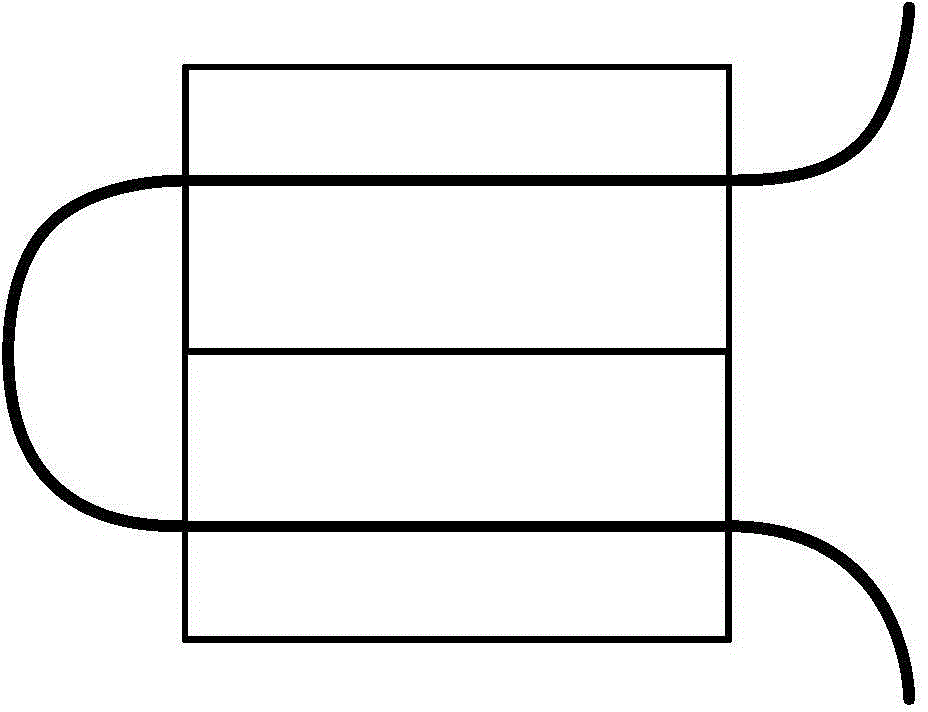

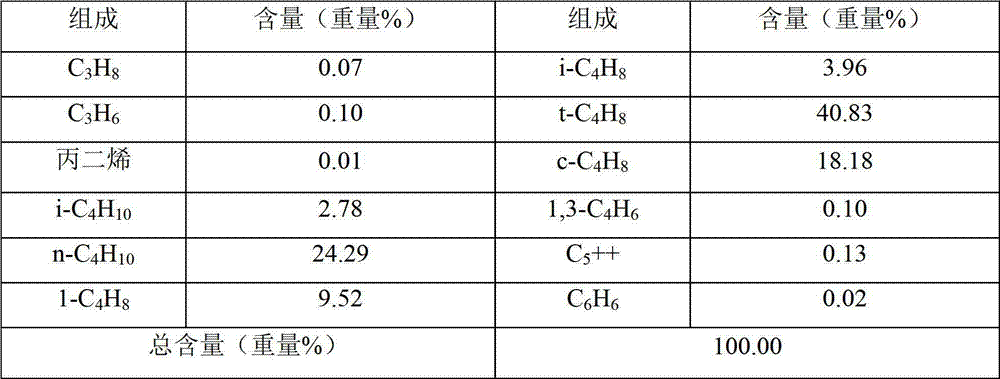

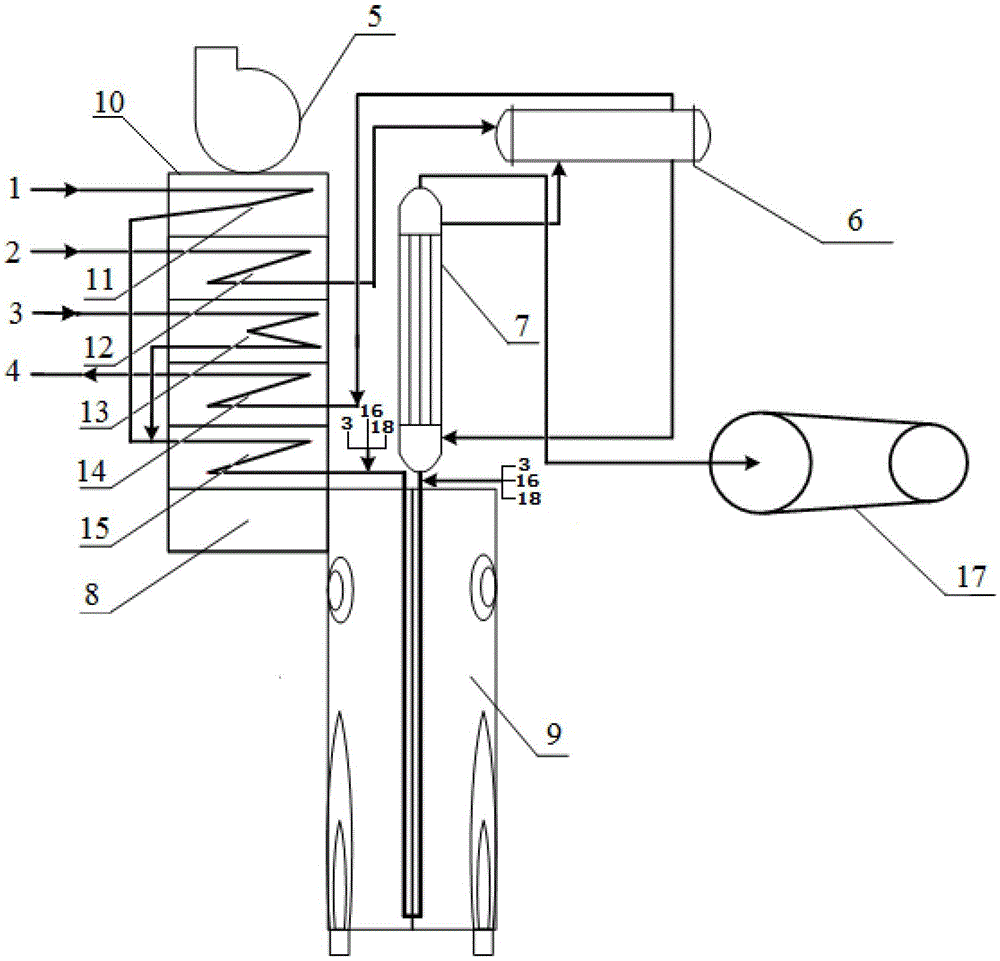

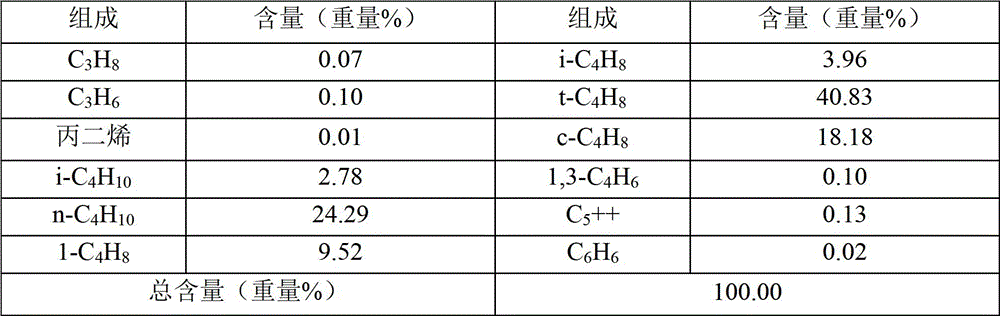

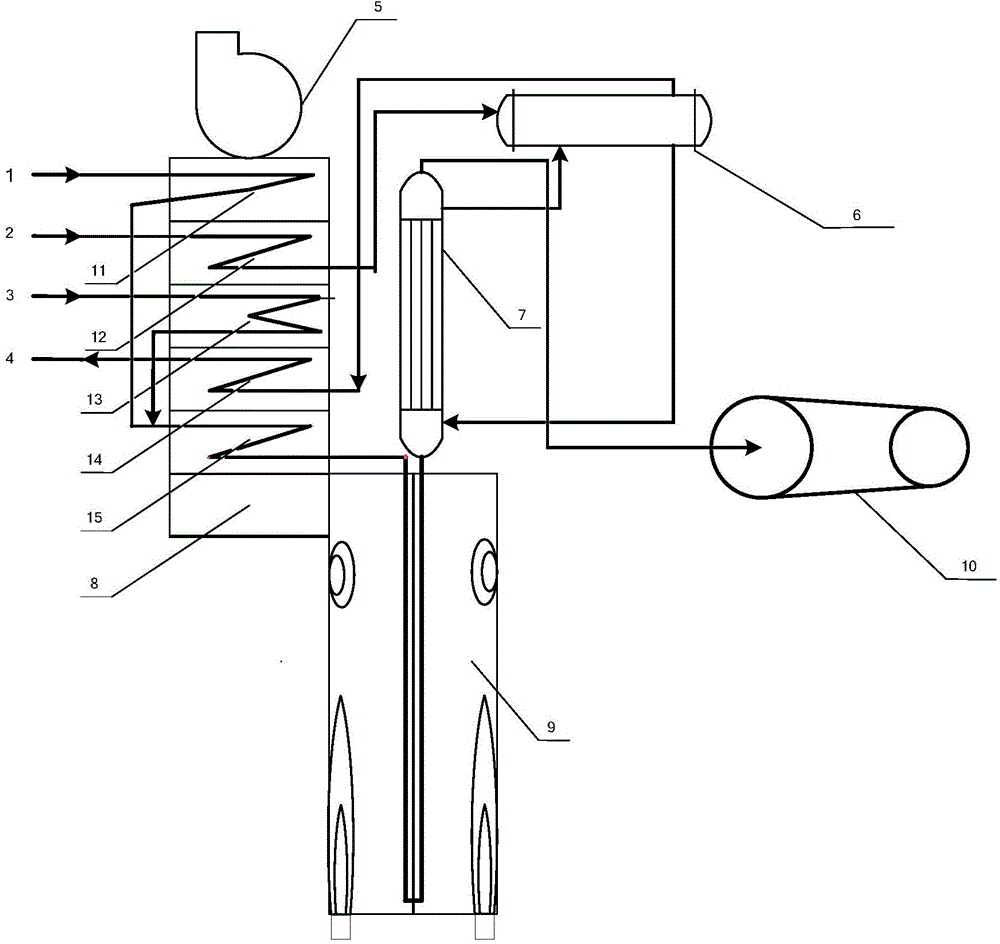

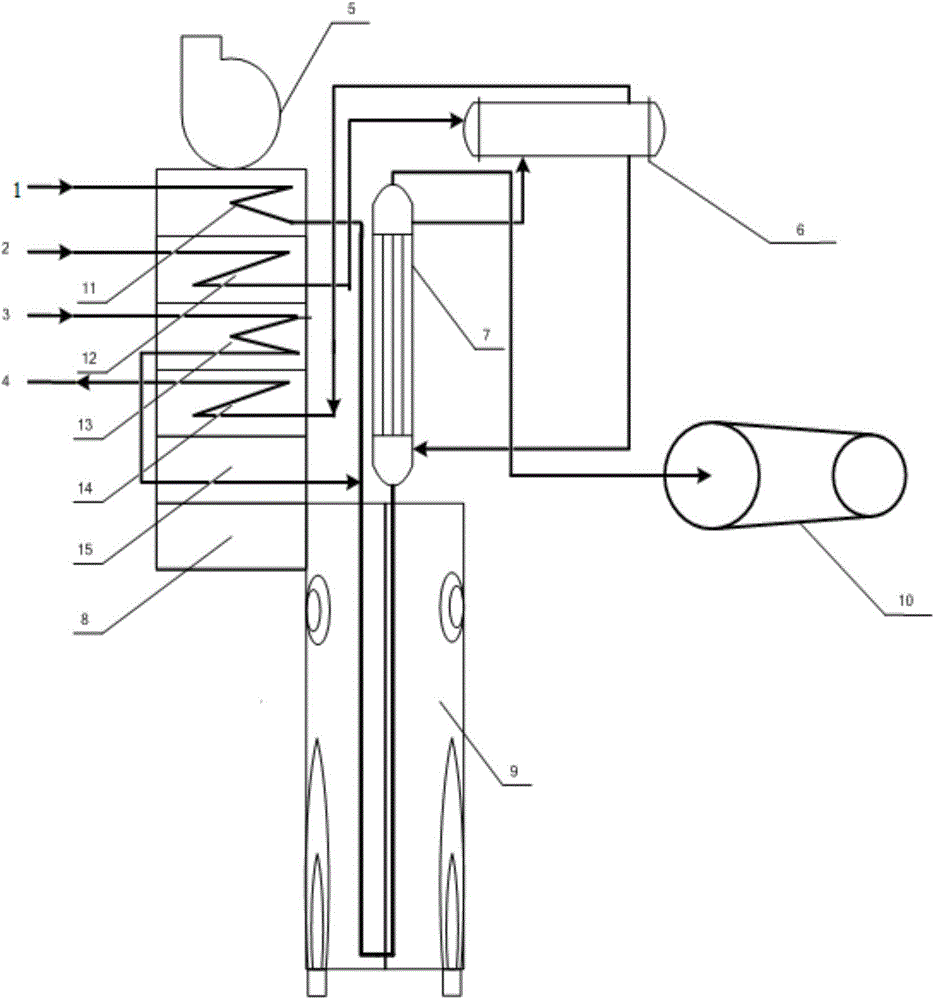

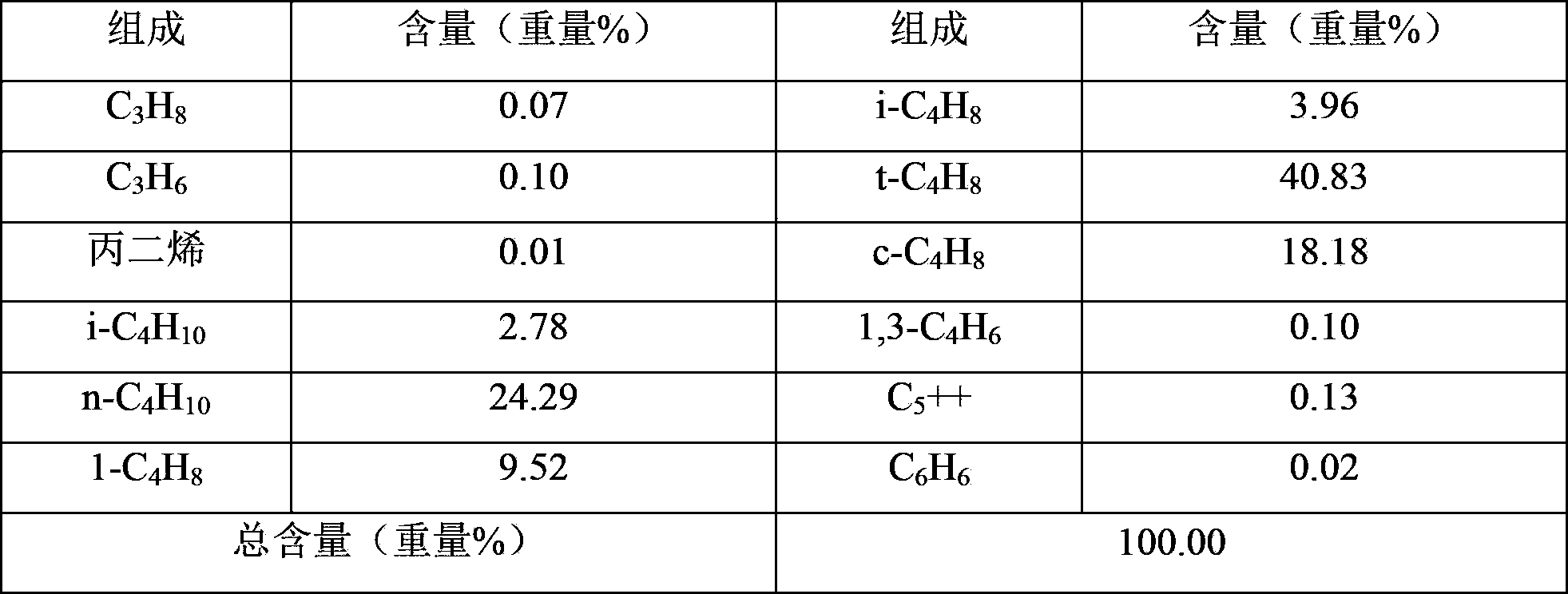

Steam cracking method

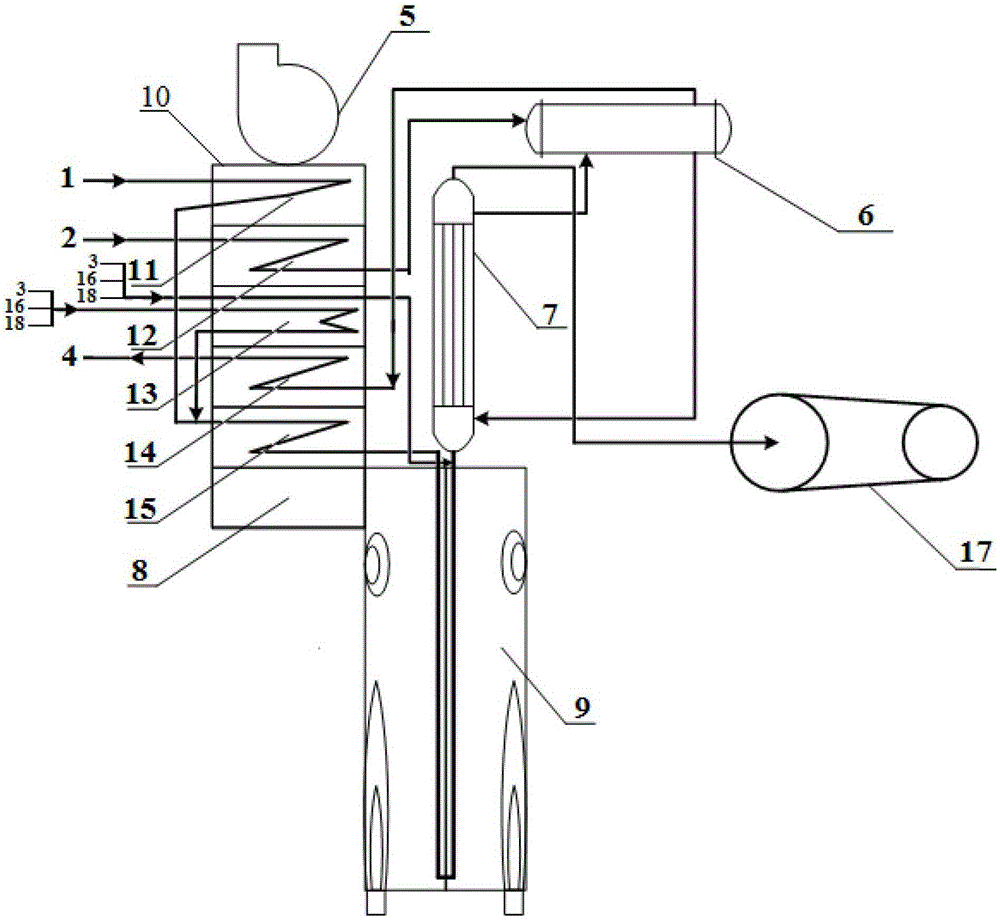

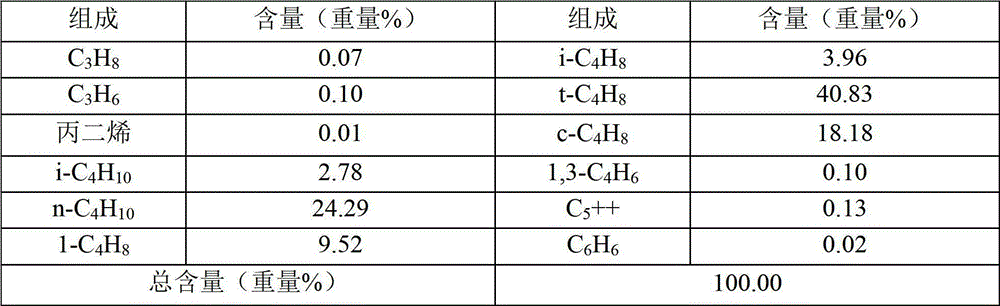

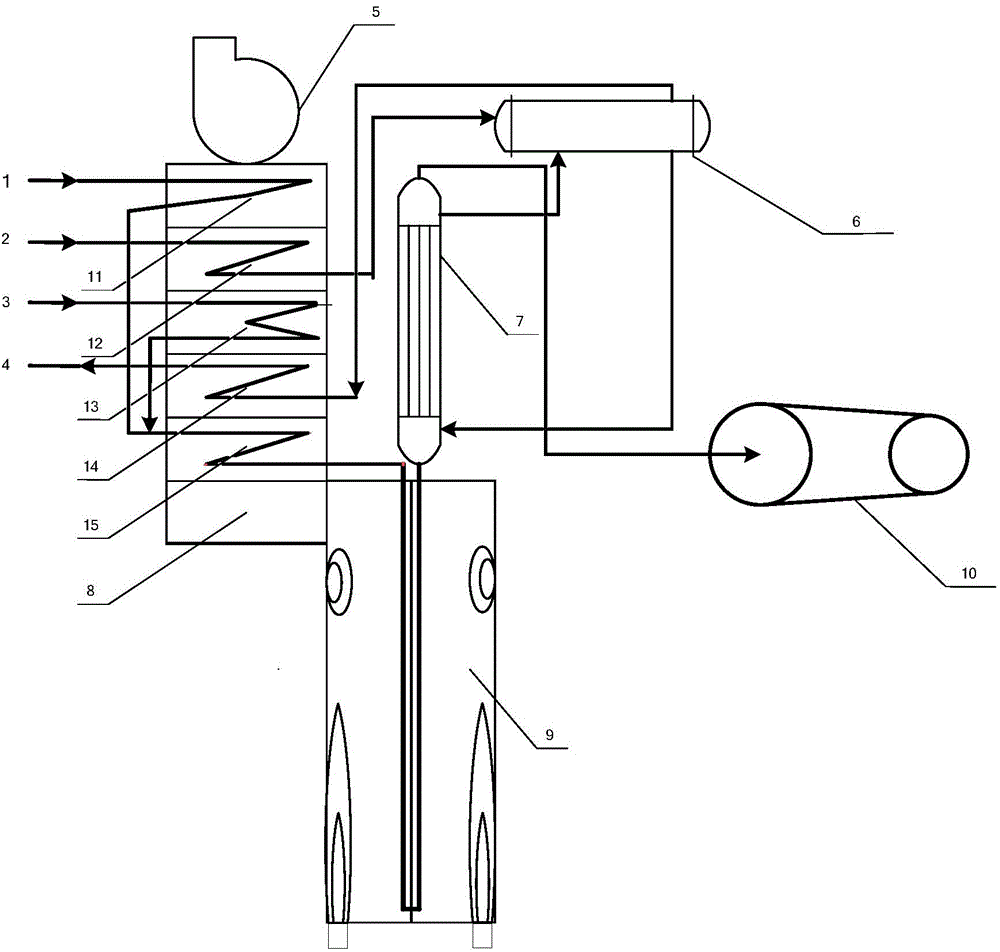

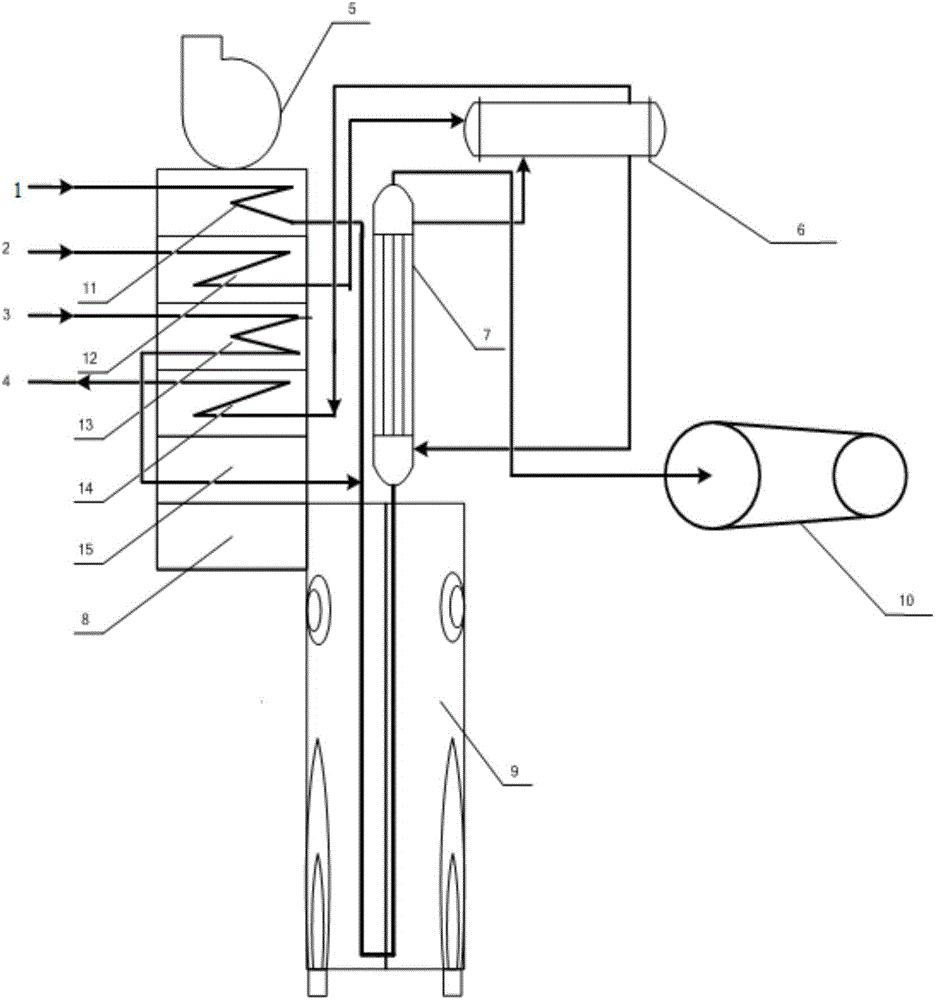

InactiveCN105622313AFast heatingHigh selectivityHydrocarbon by hydrocarbon crackingUnsaturated hydrocarbonVaporization

The invention discloses a steam cracking method. The method is enforced in a vaporization device and a cracking furnace, the cracking furnace comprises a convection section and a radiation section, and the method comprises the following steps: vaporizing unsaturated hydrocarbons in the vaporization device, mixing the vaporized gaseous unsaturated hydrocarbons with dilution steam, preheating the above obtained cracking raw material mixture to the convection section of the cracking furnace, introducing the preheated cracking raw material mixture from the middle position of the radiation section of the cracking furnace, and carrying out a cracking reaction, wherein the middle position of the radiation section of the cracking furnace is the 1 / 4-4 / 5 position of the height of the cracking furnace. The cracking raw material is preheated in the convection section to a certain temperature, and the preheated cracking raw material directly enters the cracking furnace from the middle position of the radiation section of the cracking and undergoes the cracking reaction, so the heating speed of the cracking raw material in a cracking furnace tube is improved in order to improve the selectivity of the cracking reaction, thereby the yield of ethylene, propylene and butadiene is substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

The invention discloses a steam cracking method, and the method comprises the following steps: mixing water vapor with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in a convection section to the stretch-across temperature, and then adding the heated cracking feedstock mixture into a radiation section for cracking reaction, and then injecting an obtained cracking reaction product into a rapid-cooling device for cooling and separating. The method also comprises introduction of an olefin, hydrogen and water vapor mixture at an inlet port of the convection section and / or the radiation section. According to the steam cracking method, in a steam cracking process, an olefin is introduced as a partial cracking feedstock, coking in the convection section of a cracking furnace and the rapid-cooling device may not be produced, the heat from high temperature cracking products of the radiation section can be effectively used, and the yield of butadiene may be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

ActiveCN103788988ALong runGuaranteed uptimeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingWater vaporVaporization

The invention discloses a steam cracking method implemented in cracking equipment including a cracking furnace and a rapid-cooling device, the cracking furnace comprises a convection section and a radiation section, and the method comprises the following steps: mixing an olefin and water vapor mixture with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in the convection section for vaporization of the cracking feedstock mixture, heating up to the stretch-across temperature, adding the vaporized cracking feedstock mixture into the radiation section for first cracking reaction to obtain a first cracking reaction product; mixing an olefin-containing material flow with the first cracking reaction product at an outlet port of the radiation section for second cracking reaction to obtain a second cracking reaction product, and then injecting the obtained second cracking reaction product into the rapid-cooling device for cooling and separating. According to the steam cracking method, coking of the olefin as a cracking feedstock in the convection section of the cracking furnace can be reduced, then cracking furnace operation can be long-term and stable, and the heat from high temperature cracking products of the radiation section can be effectively recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

InactiveCN105622323AAvoid cokingReduce the possibilityThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingChemistryDiameter ratio

The invention discloses a steam cracking method. The method comprises the following steps: vaporizing unsaturated hydrocarbons in a vaporization device, mixing the vaporized gaseous unsaturated hydrocarbons with dilution steam, introducing the above obtained cracking raw material mixture to the convection section of a cracking furnace, preheating the cracking raw material mixture, introducing the preheated cracking raw material mixture from the middle position of the radiation section of the cracking furnace, and carrying out a cracking reaction, wherein a diameter ratio of a preheating row to a connecting box is 1:5-12, and preferably 1:8-10, and the middle position of the radiation section of the cracking furnace is the 1 / 4-1 / 5 position of the height of the cracking furnace. The steam cracking method improves the heating speed of the cracking raw material in a cracking furnace tube in order to improve the selectivity of the cracking reaction, so the yield of ethylene, propylene and butadiene is substantially improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

ActiveCN103788990ALong runGuaranteed uptimeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingHydrogenWater vapor

The invention discloses a steam cracking method implemented in cracking equipment including a cracking furnace and a rapid-cooling device, the cracking furnace comprises a convection section and a radiation section, the method comprises the following steps: mixing an olefin, hydrogen and water vapor mixture with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in the convection section for vaporization of the cracking feedstock mixture, heating up to the stretch-across temperature, adding the vaporized cracking feedstock mixture into the radiation section for first cracking reaction to obtain a first cracking reaction product; mixing an olefin-containing material flow with the first cracking reaction product at an outlet port of the radiation section for second cracking reaction to obtain a second cracking reaction product, and then injecting the second cracking reaction product into the rapid-cooling device for cooling and separating. According to the steam cracking method, coking of the olefin as a cracking feedstock in the convection section of the cracking furnace can be reduced, the cracking furnace operation can be long-term and stable, and the heat from high temperature cracking products of the radiation section can be effectively recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

A steam cracking method comprises the following steps: mixing a liquid cracking raw material with water steam, heating the above obtained cracking raw material mixture in a convection section to an across temperature, carrying out a cracking reaction, injecting the above obtained cracking reaction product into a quenching apparatus, and cooling and separating, wherein the method also comprises at least one of the following two processes: 1, the heated cracking raw material mixture is mixed with a material flow containing olefin before the heated cracking raw material mixture is added to a radiant section; and 2, the cracking reaction product contacts and reacts with the material flow containing olefin before the cracking reaction product is injected to the quenching apparatus. The method allows the material flow containing olefin to be introduced at the outlet and / or inlet of the radiant section, so coking generated in the convection section of a cracking furnace and in the quenching apparatus does not appear, the effective utilization of heat of high temperature cracking products from the radiant section can be realized, and the butadiene yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A steam cracking method

InactiveCN103588602AVaporization fastLong runHydrocarbon by hydrocarbon crackingMetallurgyWater vapor

The invention relates to a steam cracking method. The method is implemented in a cracking furnace. The cracking furnace comprises a convection section and a radiation section. The method includes mixing a mixture of alkenes and water vapour with a liquid cracking raw material; heating the obtained cracking raw material mixture by the convection section so that the cracking raw material mixture is vaporized and heated to a cross-over temperature; and adding the vaporized cracking raw material mixture to the radiation section to perform a cracking reaction. By the method provided by the invention, coking of the alkenes as the cracking raw materials in the convection section of the cracking furnace can be reduced, and the cracking furnace can be operated stably for long time.

Owner:CHINA PETROLEUM & CHEM CORP +1

A steam cracking method

ActiveCN103788990BOvercome cokingThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingHydrogenWater vapor

The invention discloses a steam cracking method implemented in cracking equipment including a cracking furnace and a rapid-cooling device, the cracking furnace comprises a convection section and a radiation section, the method comprises the following steps: mixing an olefin, hydrogen and water vapor mixture with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in the convection section for vaporization of the cracking feedstock mixture, heating up to the stretch-across temperature, adding the vaporized cracking feedstock mixture into the radiation section for first cracking reaction to obtain a first cracking reaction product; mixing an olefin-containing material flow with the first cracking reaction product at an outlet port of the radiation section for second cracking reaction to obtain a second cracking reaction product, and then injecting the second cracking reaction product into the rapid-cooling device for cooling and separating. According to the steam cracking method, coking of the olefin as a cracking feedstock in the convection section of the cracking furnace can be reduced, the cracking furnace operation can be long-term and stable, and the heat from high temperature cracking products of the radiation section can be effectively recovered.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

The present invention discloses a steam cracking method, which is performed in a vaporization apparatus and a cracking furnace, wherein the cracking furnace comprises a convection section and a radiation section. The method comprises that unsaturated hydrocarbon is vaporized in the vaporization apparatus, diluted steam is pre-heated in the convection section of the cracking furnace, the vaporized gas-phase unsaturated hydrocarbon and the pre-heated diluted steam are mixed, and the obtained mixture is introduced from the top portion of the radiation section of the cracking furnace so as to be subjected to a cracking reaction. According to the present invention, the unsaturated hydrocarbon is adopted as the cracking raw material, the pre-heated temperature of the cracking raw material in the convection section is low, and the temperature of the unsaturated hydrocarbon in the convection section pre-heating alignment tube is reduced so as to reduce the coking rate of the unsaturated hydrocarbon in the pre-heating alignment tube and slow or avoid the coking of the cracking raw material during the pre-heating process in the convection section, such that the possibility of the cracking furnace work stopping caused by the coking at the convection section is reduced, and the smooth operating of the cracking furnace is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

ActiveCN105623709AReduce cokingIncreased coking rateThermal non-catalytic crackingDiameter ratioConvection

The invention discloses a steam cracking method. The method is enforced in a vaporization device and a cracking furnace, the cracking furnace comprises a convection section and a radiation section, the convection section comprises preheating tube rows and a connecting box positioned outside the convection section of the cracking furnace and between the preheating tube rows, and the method comprises the following steps: vaporizing unsaturated hydrocarbons in a vaporization device, mixing the vaporized gaseous unsaturated hydrocarbons with dilution steam, introducing the above obtained cracking raw material mixture to the convection section of the cracking furnace, preheating the cracking raw material mixture, introducing the preheated cracking raw material mixture from the top of the radiation section of the cracking furnace, and carrying out a cracking reaction, wherein a diameter ratio of the preheating rows to the connecting box is 1:5-12, and preferably 1:8-10. The method can reduce the possibility of cracking furnace shutdown induced by convection section coking in order to ensure stable running of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

ActiveCN103788991AHigh yieldOvercome cokingThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingHydrogenWater vapor

A steam cracking method comprises the following steps: mixing a liquid cracking raw material with water steam, heating the above obtained cracking raw material mixture in a convection section to an across temperature, adding the heated cracking raw material mixture into a radiant section, carrying out a cracking reaction, injecting the above obtained cracking reaction product into a quenching apparatus, and cooling and separating, wherein the method also comprises a step that a material flow containing olefin is added at the inlet and / or outlet of the radiant section, and the material flow containing olefin is a mixture containing heated olefin and hydrogen, or a mixture containing the heated olefin, hydrogen and the water steam. The method allows olefin to be introduced at the outlet and / or inlet of the radiant section, so coking generated in the convection section of a cracking furnace and in the quenching apparatus does not appear, the effective utilization of heat of high temperature cracking products from the radiant section can be realized, and the butadiene yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

The invention discloses a steam cracking method. The method is enforced in a vaporization device and a cracking furnace, the cracking furnace comprises a convection section and a radiation section, and the method comprises the following steps: vaporizing unsaturated hydrocarbons in the vaporization device, preheating dilution steam in the convection section of the cracking furnace, mixing the vaporized gaseous unsaturated hydrocarbons with preheated dilution steam, introducing the above obtained cracking raw material mixture from the middle position of the radiation section of the cracking furnace, and carrying out a cracking reaction, wherein the middle position of the radiation section of the cracking furnace is the 1 / 4-4 / 5 position of the height of the cracking furnace. The method reduces the temperature of the unsaturated hydrocarbons in a convection section preheating tube row in order to reduce the coking rate of the unsaturated hydrocarbons in the convection section preheating tube row, so coking of a cracking raw material in the convection section preheating process is alleviated or avoided, thereby the possibility of cracking furnace shutdown induced by convection section coking is reduced in order to ensure stable running of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

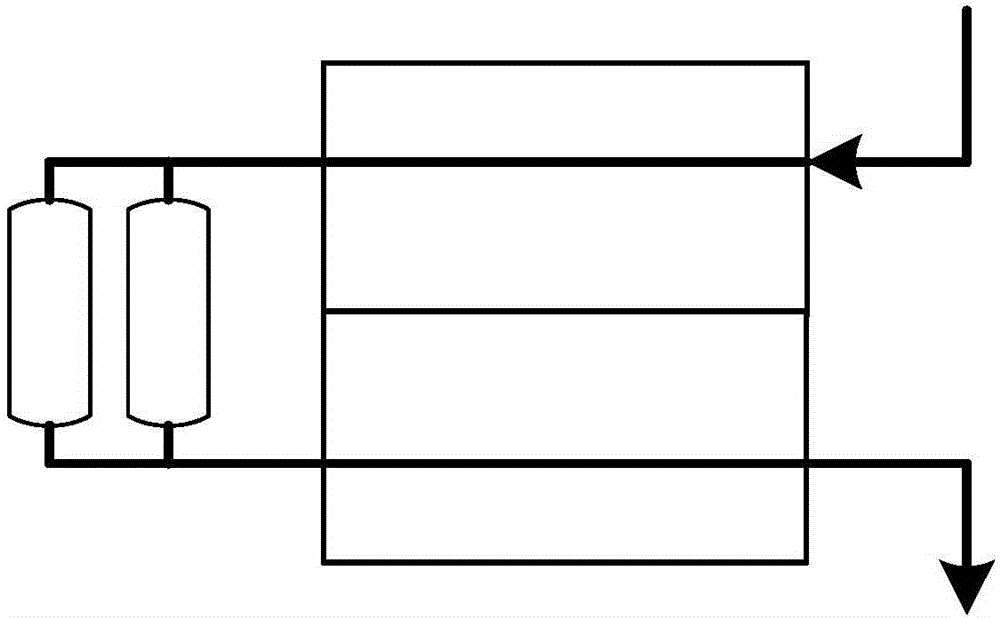

Steam cracking method

InactiveCN105541531AReduce cokingIncreased coking rateHydrocarbon by hydrocarbon crackingUnsaturated hydrocarbonGas phase

The present invention discloses a steam cracking method, which is performed in a vaporization apparatus and a cracking furnace, wherein the cracking furnace comprises a convection section and a radiation section, and the convection section comprises pre-heating alignment tubes and a connection box positioned between the pre-heating alignment tubes outside the cracking furnace convection section. The method comprises that unsaturated hydrocarbon is vaporized in the vaporization apparatus to obtain gas-phase unsaturated hydrocarbon, the gas-phase unsaturated hydrocarbon and diluted steam are mixed, pre-heating is performed, one part of the pre-heated mixture is introduced into the outlet position of the cracking furnace radiation section, and the other part is introduced from the middle position of the cracking furnace radiation section and is cracked, wherein a diameter ratio of the pre-heating alignment tubes to the connection box is 1:5-12, and the middle position of the cracking furnace radiation section is positioned at the place having the height of 1 / 4-4 / 5 of the height of the cracking furnace. With the method of the present invention, the temperature increasing rate of the cracking raw material in the cracking furnace tube is improved so as to improve the selectivity of the cracking reaction, such that the yields of ethylene, propylene and butadiene are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

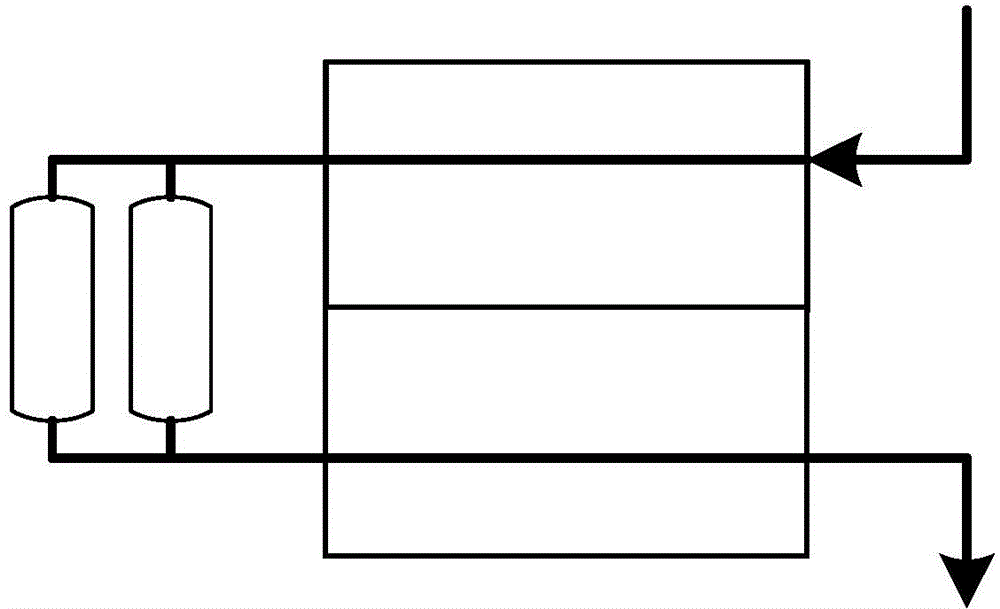

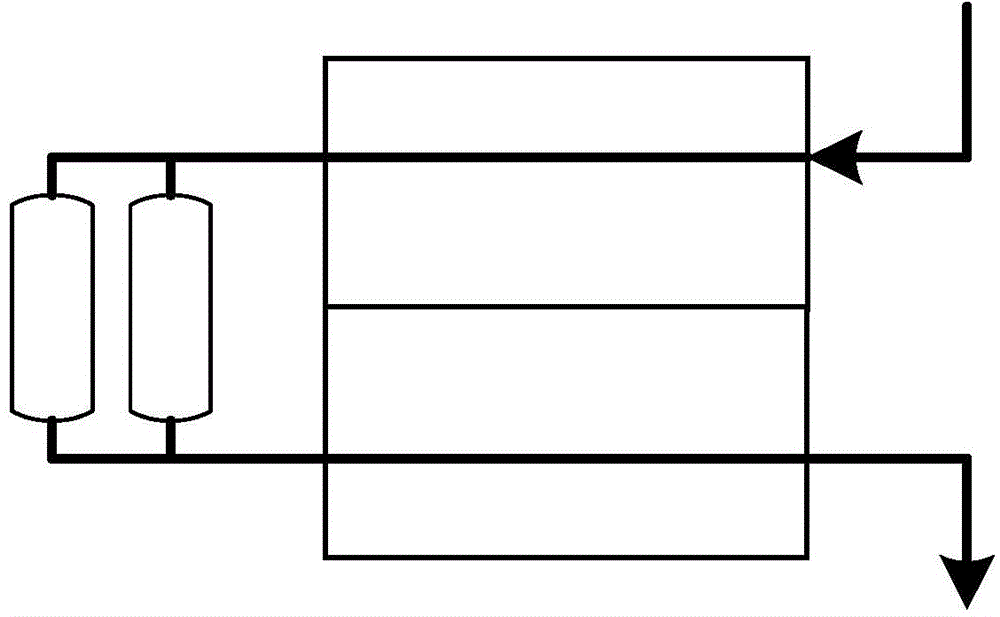

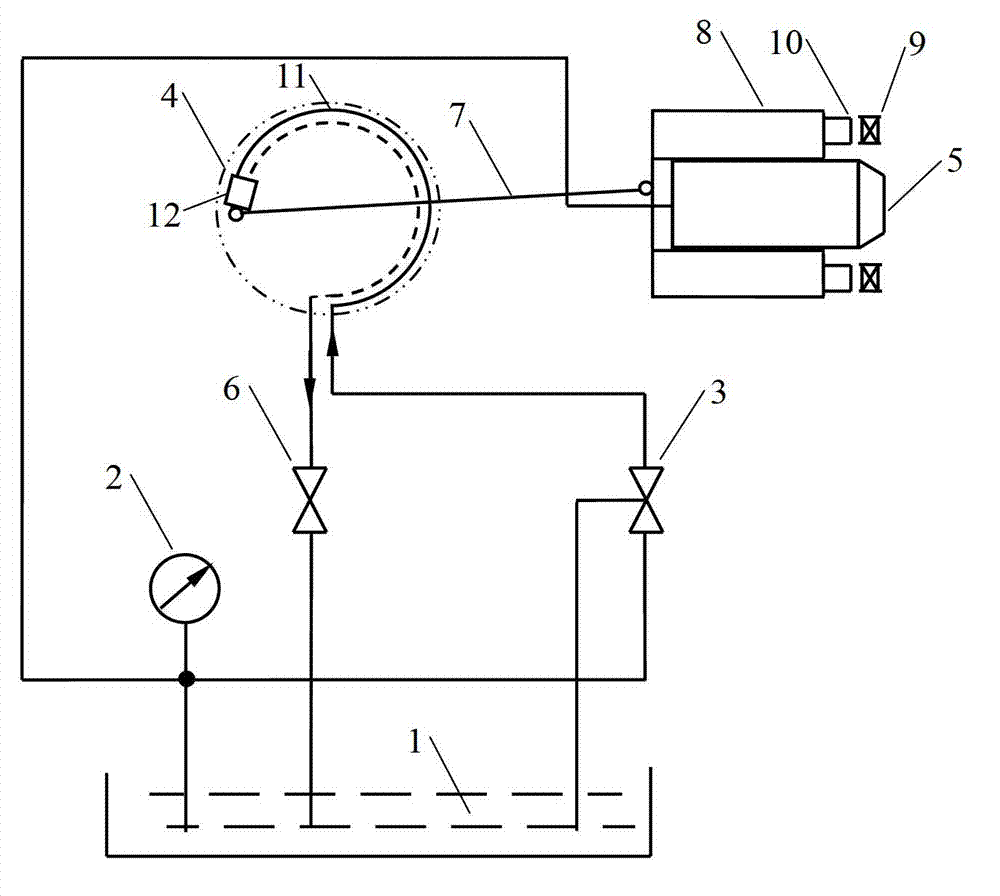

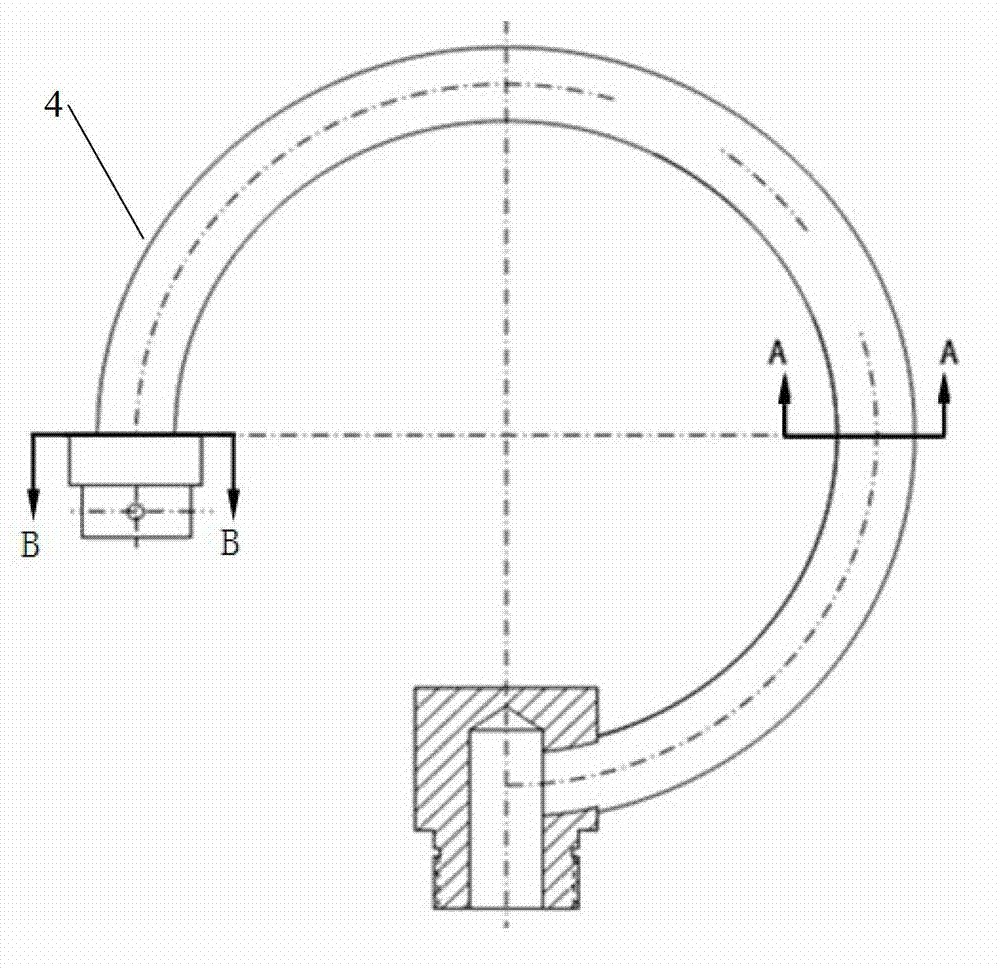

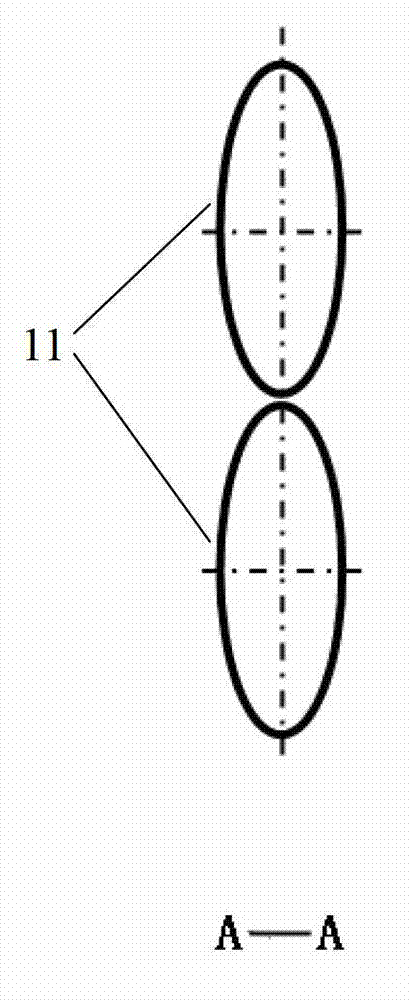

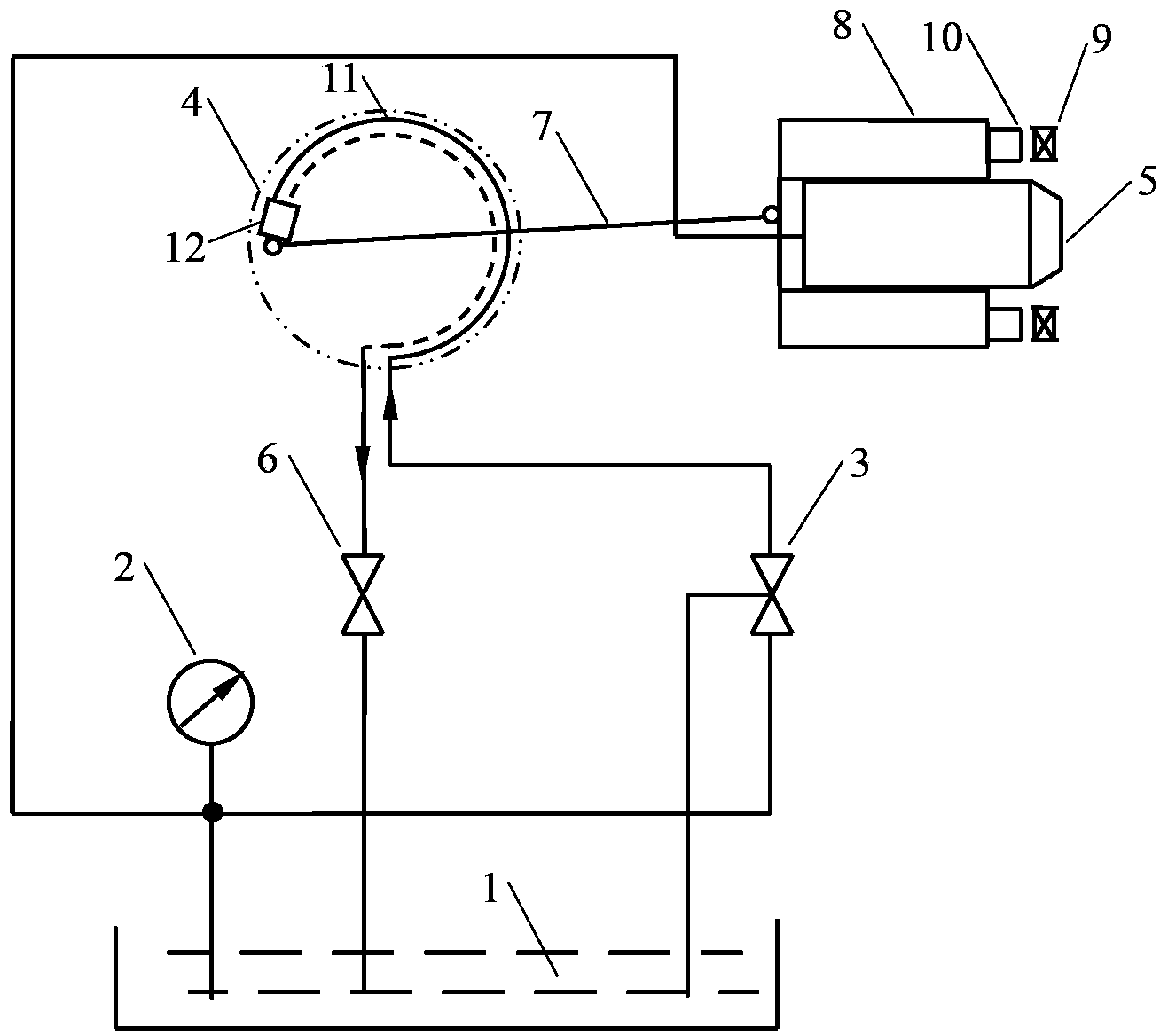

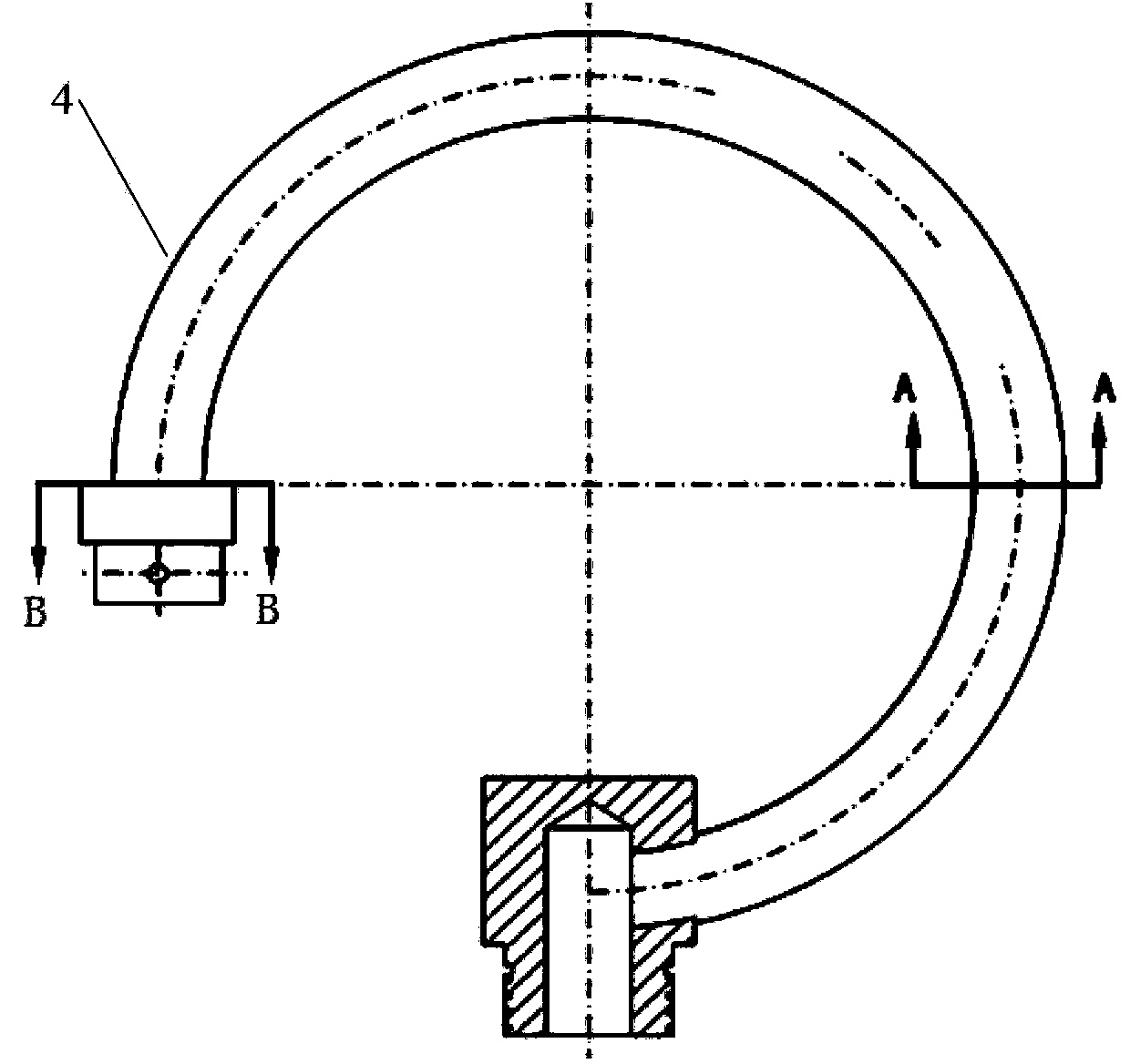

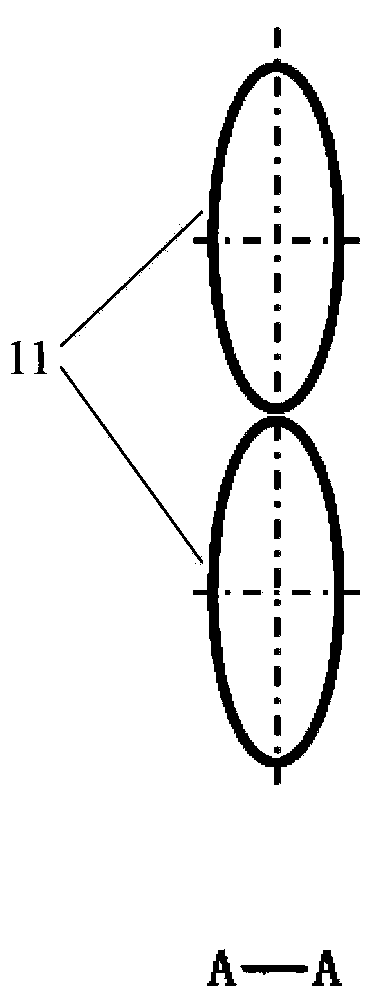

Active control mechanism for broadening lean burn flameout boundary of combustion chamber of heavy duty gas turbine

ActiveCN102877949AOvercome carbon deposition and cokingExtended service lifeGas turbine plantsJet propulsion plantsSpray nozzleGas turbines

The invention discloses an active control mechanism for broadening a lean burn flameout boundary of a combustion chamber of a heavy duty gas turbine. The active control mechanism comprises an oil supply system, an oil pump, an overflow valve, an elastic element, a nozzle, a backpressure valve, a connecting rod, a sleeve and an axial cyclone. The elastic element comprises two spring tubes which are arranged in parallel and a closed cavity, and the tail ends of the spring tubes are communicated with the closed cavity to form a free end of the elastic element. The oil pump is communicated with the oil supply system and is respectively connected with the inlet ends of the nozzle and the overflow valve; an overflow port of the overflow valve and the outlet end of the backpressure valve are communicated with the oil supply system; the inlet end of the elastic element is connected with the outlet end of the overflow valve; the outlet end of the elastic element is connected with the inlet end of the backpressure valve; the free end of the elastic element is hinged with the connecting rod; and the connecting rod is hinged with the sleeve. According to the active control mechanism, the lean burn flameout boundary of the combustion chamber of the heavy duty gas turbine is effectively broadened, the phenomenon of coking and carbon deposition due to immobilization of fuel in the single spring tube can be solved, and the service life of the control mechanism is prolonged.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

A kind of steam cracking method

ActiveCN103788991BOvercome cokingThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingHydrogenWater vapor

A steam cracking method comprises the following steps: mixing a liquid cracking raw material with water steam, heating the above obtained cracking raw material mixture in a convection section to an across temperature, adding the heated cracking raw material mixture into a radiant section, carrying out a cracking reaction, injecting the above obtained cracking reaction product into a quenching apparatus, and cooling and separating, wherein the method also comprises a step that a material flow containing olefin is added at the inlet and / or outlet of the radiant section, and the material flow containing olefin is a mixture containing heated olefin and hydrogen, or a mixture containing the heated olefin, hydrogen and the water steam. The method allows olefin to be introduced at the outlet and / or inlet of the radiant section, so coking generated in the convection section of a cracking furnace and in the quenching apparatus does not appear, the effective utilization of heat of high temperature cracking products from the radiant section can be realized, and the butadiene yield is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

InactiveCN105622311AOvercome cokingHydrocarbon by hydrocarbon crackingUnsaturated hydrocarbonCoke rate

The invention discloses a steam cracking method. The method is enforced in a vaporization device and a cracking furnace, the cracking furnace comprises a convection section and a radiation section, and the method comprises the following steps: vaporizing unsaturated hydrocarbons in the vaporization device, preheating dilution steam in the convection section of the cracking furnace, introducing parts of a mixture obtained after mixing vaporized gaseous unsaturated hydrocarbons with preheated dilution steam to the outlet of the radiation section of the cracking furnace, and introducing the remaining mixture from the middle position of the radiation section of the cracking furnace, wherein the middle position of the radiation section of the cracking furnace is the 1 / 4-1 / 5 position of the height of the cracking furnace. The method reduces the temperature of the unsaturated hydrocarbons in a convection section preheating tube row in order to reduce the coking rate of the unsaturated hydrocarbons in the convection section preheating tube row, so coking of a cracking raw material in the convection section preheating process is alleviated or avoided, thereby the possibility of cracking furnace shutdown induced by convection section coking is reduced in order to ensure stable running of the cracking furnace.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of steam cracking method

The invention discloses a steam cracking method, and the method comprises the following steps: mixing water vapor with a liquid cracking feedstock, then heating in a convection section to the stretch-across temperature, and then entering into a radiation section for cracking reaction, and then injecting an obtained cracking reaction product into a rapid-cooling device for cooling and separating. The method also comprises at least one of the flowing to processes: before a heated cracking feedstock mixture is added into the radiation section, the heated cracking feedstock mixture is mixed with an olefin; and (2) before the cracking reaction product is injected into the rapid-cooling device, the cracking reaction product is contacted with the olefin for reaction. According to the steam cracking method, by addition of the olefin at the outlet port and / or the inlet port of the radiation section, coking in the convection section of a cracking furnace and the rapid-cooling device may not be produced, the heat from high temperature cracking products of the radiation section can be effectively used, and the yield of butadiene may be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

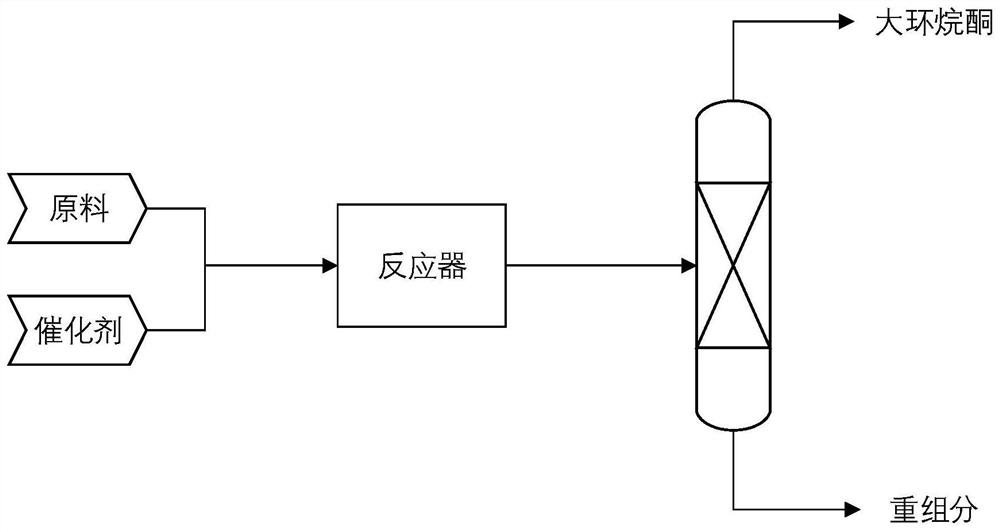

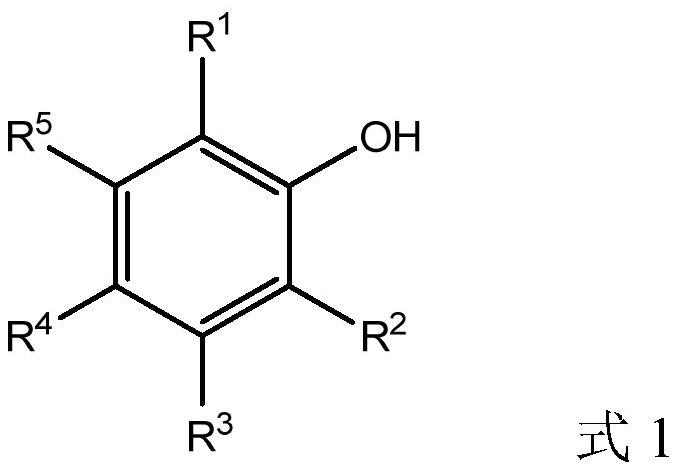

Method for preparing macrocycloalkanone from epoxide

ActiveCN113461504AOvercome carbon depositsOvercome cokingOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from heterocyclic compoundsIsomerizationPtru catalyst

The invention provides a method for preparing a macrocycloalkanone from an epoxide. The method comprises the following steps of: mixing a ligand L, an aluminum compound and a solvent to obtain a catalyst solution; injecting the catalyst solution and an epoxide into a reactor for reaction to obtain a reaction solution; and separating and purifying the reaction liquid to obtain the required product. Compared with the prior art, the method provided by the invention has the advantages that the reaction conditions are milder, the macrocycloalkanone can be prepared at the temperature of 50-100 DEG C, the problems of side reactions such as oxidation, isomerization and decomposition of raw materials and products and carbon deposition and coking of a catalyst caused by high-temperature reaction at 200 DEG C or above in the prior art are solved, high-selectivity and high-yield continuous preparation of the macrocycloalkanone compound is realized, generation of high-boiling-point byproducts with functional groups and similar carbon atom numbers is avoided, and the product separation difficulty and the operation difficulty are greatly reduced.

Owner:CHINA TIANCHEN ENG

Supercritical Hydrothermal Combustion Reactor for Heavy Oil Injection and Production

InactiveCN103900094BStable combustionGood for burnoutFluid removalIncinerator apparatusCombustorCombustion chamber

The invention belongs to the field of energy and environments, and particularly relates to a supercritical water heat combustion reactor for thick oil injection production. The supercritical water heat combustion reactor for thick oil injection production comprises a reaction chamber, an upper top cover and a lower bottom cover, wherein the reaction chamber is hollow, openings are formed in the upper end and the lower end of the reaction chamber respectively, the upper top cover is connected with the opening formed in the upper end of the reaction chamber in a sealed mode, the lower bottom cover is connected with the opening formed in the lower end of the reaction chamber, and a closed space is formed by the reaction chamber, the upper top cover and the lower bottom cover; a cylindrical stepped hollow portion is formed in the center of the upper top cover, a stepped hollow portion on the lower portion of the cylindrical stepped hollow portion serves as a combustor, a stepped hollow portion on the upper portion of the cylindrical stepped hollow portion serves as a communicated fuel inlet, an annular groove is formed in the outer side of the lower end of the stepped hollow portion on the upper portion of the cylindrical stepped hollow portion, the lower portion of the annular groove is communicated with the combustor, and the annular groove is communicated with an oxidizing agent inlet formed in the side face of the upper top cover; a mixing chamber is arranged at the bottom of the combustor, an annular gap formed between the upper top cover and the reaction chamber is formed in the side of the combustor, and the annular gap is communicated with a supplementary water inlet formed in the side face of the reaction chamber.

Owner:TAIYUAN UNIV OF TECH

A kind of steam cracking method

The invention discloses a steam cracking method, and the method comprises the following steps: mixing water vapor with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in a convection section to the stretch-across temperature, and then adding the heated cracking feedstock mixture into a radiation section for cracking reaction, and then injecting an obtained cracking reaction product into a rapid-cooling device for cooling and separating. The method also comprises addition of a heated olefin or a heated olefin and water vapor mixture at an inlet port and / or an outlet port of the radiation section. According to the steam cracking method, by addition of the olefin at the outlet port and / or the inlet port of the radiation section, coking in the convection section of a cracking furnace and the rapid-cooling device may not be produced, the heat from high temperature cracking products of the radiation section can be effectively used, and the yield of butadiene may be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of steam cracking method

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

The present invention discloses a steam cracking method, which is performed in a vaporization apparatus and a cracking furnace, wherein the cracking furnace comprises a convection section and a radiation section. The method comprises that unsaturated hydrocarbon is vaporized in the vaporization apparatus, diluted steam is pre-heated in the convection section of the cracking furnace, the vaporized gas-phase unsaturated hydrocarbon and the pre-heated diluted steam are mixed, one part of the obtained cracking raw material mixture is introduced into the outlet position of the cracking furnace radiation section and is cracked, and the other part is introduced from the top portion of the cracking furnace radiation section and is cracked. With the steam cracking method of the present invention, the temperature of the unsaturated hydrocarbon in the convection section pre-heating alignment tube is reduced so as to reduce the coking rate of the unsaturated hydrocarbon in the pre-heating alignment tube and slow or avoid the coking of the cracking raw material during the pre-heating process in the convection section, such that the possibility of the cracking furnace work stopping caused by the coking at the convection section is reduced, and the smooth operating of the cracking furnace is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of steam cracking method

Owner:CHINA PETROLEUM & CHEM CORP +1

Steam cracking method

The invention discloses a steam cracking method, and the method comprises the following steps: mixing water vapor with a liquid cracking feedstock, then heating in a convection section to the stretch-across temperature, and then entering into a radiation section for cracking reaction, and then injecting an obtained cracking reaction product into a rapid-cooling device for cooling and separating. The method also comprises at least one of the flowing to processes: before a heated cracking feedstock mixture is added into the radiation section, the heated cracking feedstock mixture is mixed with an olefin; and (2) before the cracking reaction product is injected into the rapid-cooling device, the cracking reaction product is contacted with the olefin for reaction. According to the steam cracking method, by addition of the olefin at the outlet port and / or the inlet port of the radiation section, coking in the convection section of a cracking furnace and the rapid-cooling device may not be produced, the heat from high temperature cracking products of the radiation section can be effectively used, and the yield of butadiene may be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

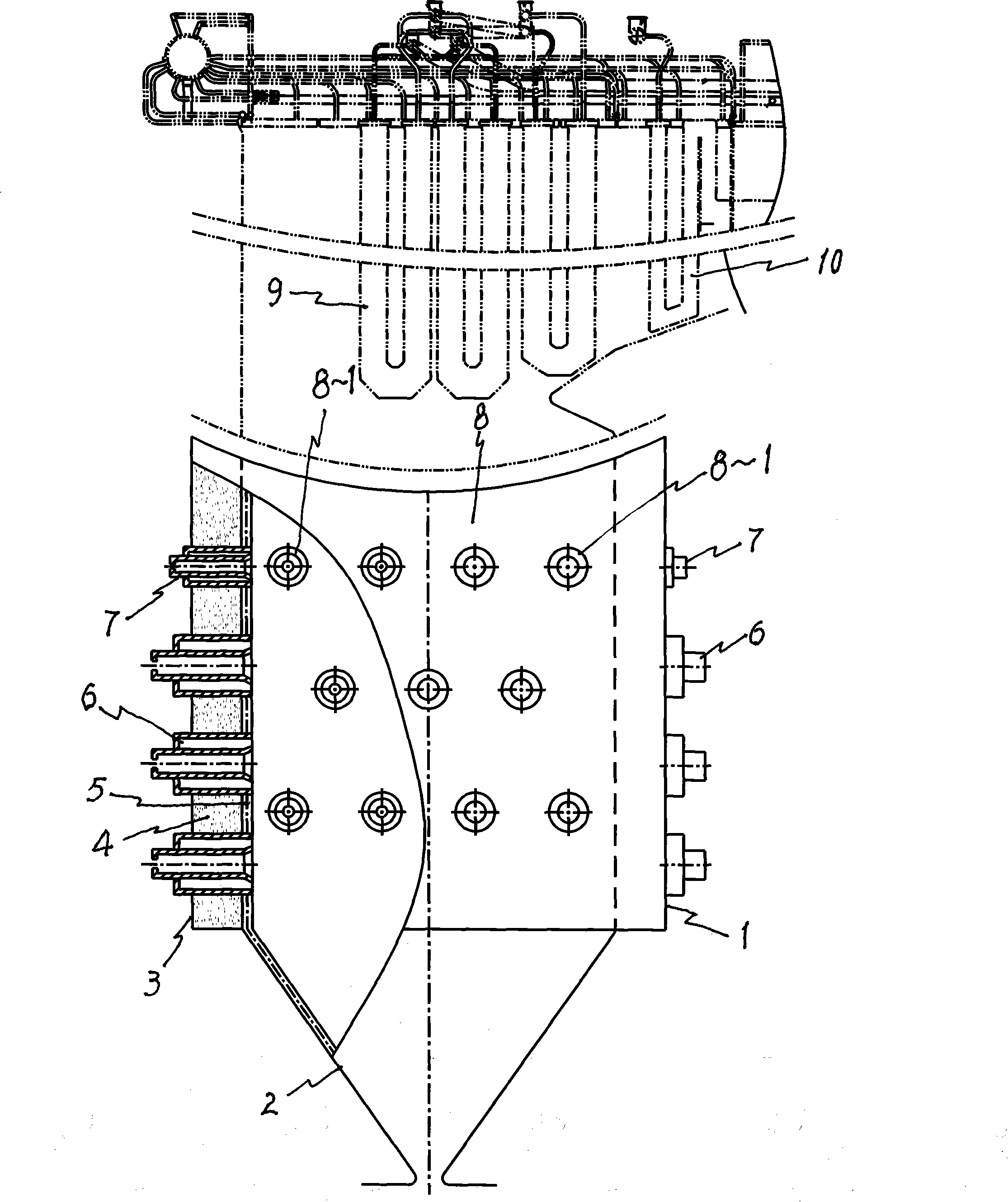

Forward and backward wall opposite rushing combustion boiler hearth as well as method for arranging air nozzle on side wall

ActiveCN101280919BHigh thermal efficiencyReduce maintenance workloadCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorCombustion chamber

The invention pertains to forward and backward wall opposed firing type utility boiler combustion chamber and method for arranging air nozzle on its side. The combustion chamber comprises a pulverized coal burner, forward and backward walls of combustion chamber of combustion wind combustor group, and a combustion chamber body arranged with air nozzle group including two-sided wall, and a combustion chamber hopper at lower part of the combustion chamber body. The method arranging air nozzle on its side is to arrange 1-6 row of air nozzles above the intersecting line of lowest pulverized coal burner shaft cross section and two-sided wall, and symmetrical with side wall centre line. By arranging a nozzle cluster capable of supplying axial flow air and side flow air to the combustion chamberon two-sided walls at same time, the invention can reduce side wall temperature at same time of improving oxygen compensation strength and boiler thermal efficiency, can effectively prevent the two-sided walls from severe coking and high-temperature corrosion, can reduce examination and repair amount of work of combustion chamber and can prolong service-life. The invention overcomes disadvantagesof low combustion efficiency, severe coking and high-temperature corrosion of the two-sided walls in background art.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Active control mechanism for broadening lean burn flameout boundary of combustion chamber of heavy duty gas turbine

ActiveCN102877949BExtended service lifeOvercome cokingGas turbine plantsJet propulsion plantsCycloneCombustion chamber

The invention discloses an active control mechanism for broadening a lean burn flameout boundary of a combustion chamber of a heavy duty gas turbine. The active control mechanism comprises an oil supply system, an oil pump, an overflow valve, an elastic element, a nozzle, a backpressure valve, a connecting rod, a sleeve and an axial cyclone. The elastic element comprises two spring tubes which are arranged in parallel and a closed cavity, and the tail ends of the spring tubes are communicated with the closed cavity to form a free end of the elastic element. The oil pump is communicated with the oil supply system and is respectively connected with the inlet ends of the nozzle and the overflow valve; an overflow port of the overflow valve and the outlet end of the backpressure valve are communicated with the oil supply system; the inlet end of the elastic element is connected with the outlet end of the overflow valve; the outlet end of the elastic element is connected with the inlet end of the backpressure valve; the free end of the elastic element is hinged with the connecting rod; and the connecting rod is hinged with the sleeve. According to the active control mechanism, the lean burn flameout boundary of the combustion chamber of the heavy duty gas turbine is effectively broadened, the phenomenon of coking and carbon deposition due to immobilization of fuel in the single spring tube can be solved, and the service life of the control mechanism is prolonged.

Owner:BEIJING HUAQING GAS TURBINE & INTEGRATED GASIFICATION COMBINED CYCLE ENG TECH

Method for preparing self-assembled all-carbon three-dimensional graphene with papermaking black liquor

The invention discloses a method for preparing self-assembly all-carbon three-dimensional graphene from papermaking black liquid. The method includes the steps of ultrasonically smashing lignin suspension liquid, using liquid nitrogen quick freezing for drying and shape maintenance, conducting medium temperature partial carbonization shaping and solidifying and performing multi-temperature multi-atmosphere procedural deoxidation carbonization treatment. Treated lignin can be kept of a loose and porous three-dimensional structure in the high-temperature carbonization process, coking and caking which are prone to occurring are avoided, the self-assembly all-carbon three-dimensional graphene material with a supporting structure is prepared, all fragments are fused closely, multiple layers are distributed in a three-dimensional mode and support one another, structural stability is enhanced, and the superficial area of graphene is increased.

Owner:GUANGXI ACAD OF SCI

Steam cracking method

ActiveCN103787806AHigh yieldOvercome cokingHydrocarbon by hydrocarbon crackingWater vaporCracking reaction

The invention discloses a steam cracking method, and the method comprises the following steps: mixing water vapor with a liquid cracking feedstock, heating an obtained cracking feedstock mixture in a convection section to the stretch-across temperature, and then adding the heated cracking feedstock mixture into a radiation section for cracking reaction, and then injecting an obtained cracking reaction product into a rapid-cooling device for cooling and separating. The method also comprises addition of a heated olefin or a heated olefin and water vapor mixture at an inlet port and / or an outlet port of the radiation section. According to the steam cracking method, by addition of the olefin at the outlet port and / or the inlet port of the radiation section, coking in the convection section of a cracking furnace and the rapid-cooling device may not be produced, the heat from high temperature cracking products of the radiation section can be effectively used, and the yield of butadiene may be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com