Active control mechanism for broadening lean burn flameout boundary of combustion chamber of heavy duty gas turbine

A gas turbine, active control technology, applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve problems such as carbon deposition, fuel coking, affecting the function and life of the control mechanism, etc., to overcome coking and carbon deposition, and prolong the service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

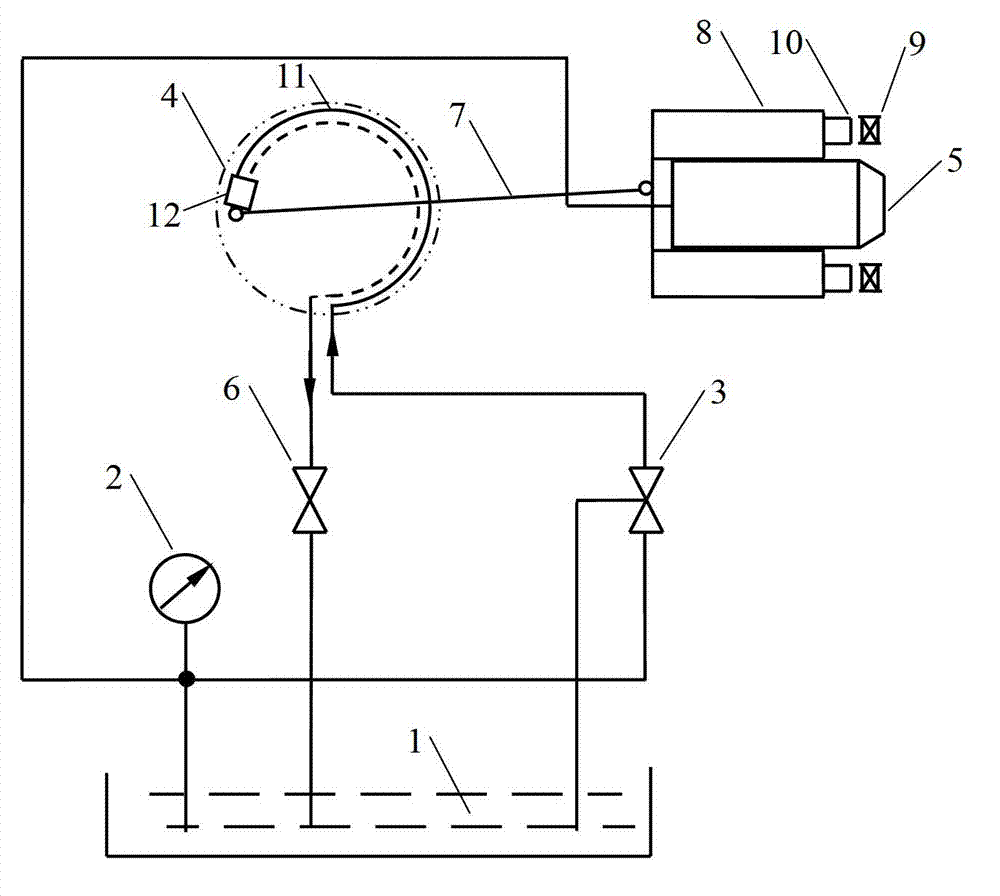

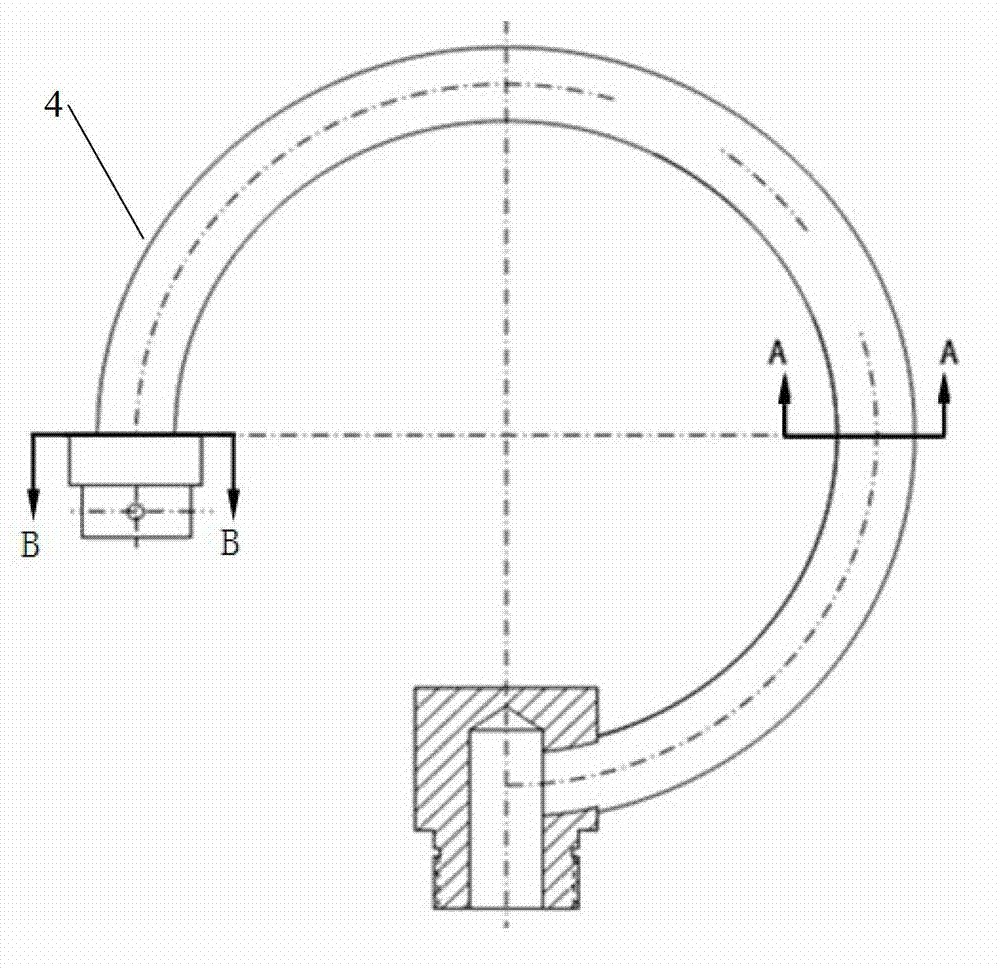

[0022] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

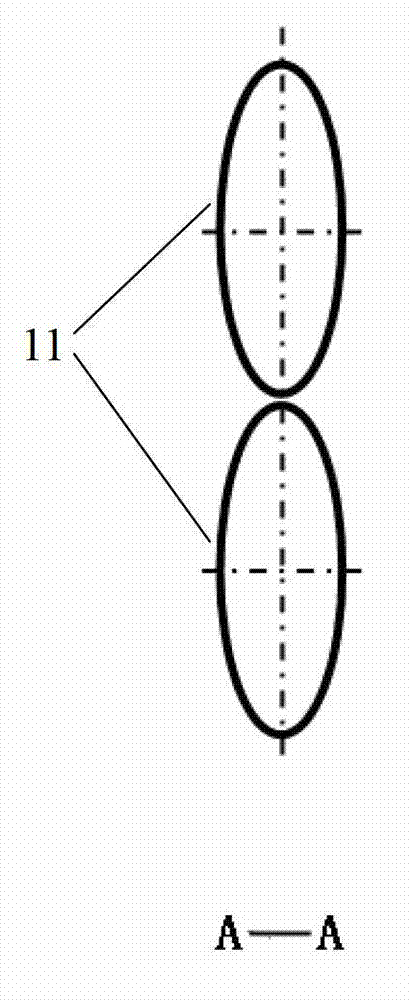

[0023] figure 1 It is a schematic diagram of the structure principle of the active control mechanism for the lean-burn and flameout boundary of the gas turbine combustor. The active control mechanism structure includes oil supply system 1, oil pump 2, relief valve 3, elastic element 4, nozzle 5, back pressure valve 6, connecting rod 7, sleeve 8, blade 10 installed on the sleeve and axial Cyclone 9. The oil pump 2 communicates with the oil supply system 1 and connects with the nozzle 5 and the inlet port of the overflow valve 3 respectively; the overflow port of the overflow valve 3 and the outlet port of the back pressure valve 6 communicate with the oil supply system 1 . The elastic element 4 is made up of two spring tubes 11 arranged side by side and a closed cavity 12, and the ends of the two spring tubes 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com