Forward and backward wall opposite rushing combustion boiler hearth as well as method for arranging air nozzle on side wall

A technology of opposed combustion and boiler furnace, applied in the direction of combustion method, combustion equipment, combustion type, etc., can solve the problems of coking on both sides of the wall, high temperature corrosion, low combustion efficiency, heavy maintenance workload, etc., to prevent serious coking and high temperature Corrosion, overcoming low combustion efficiency, and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

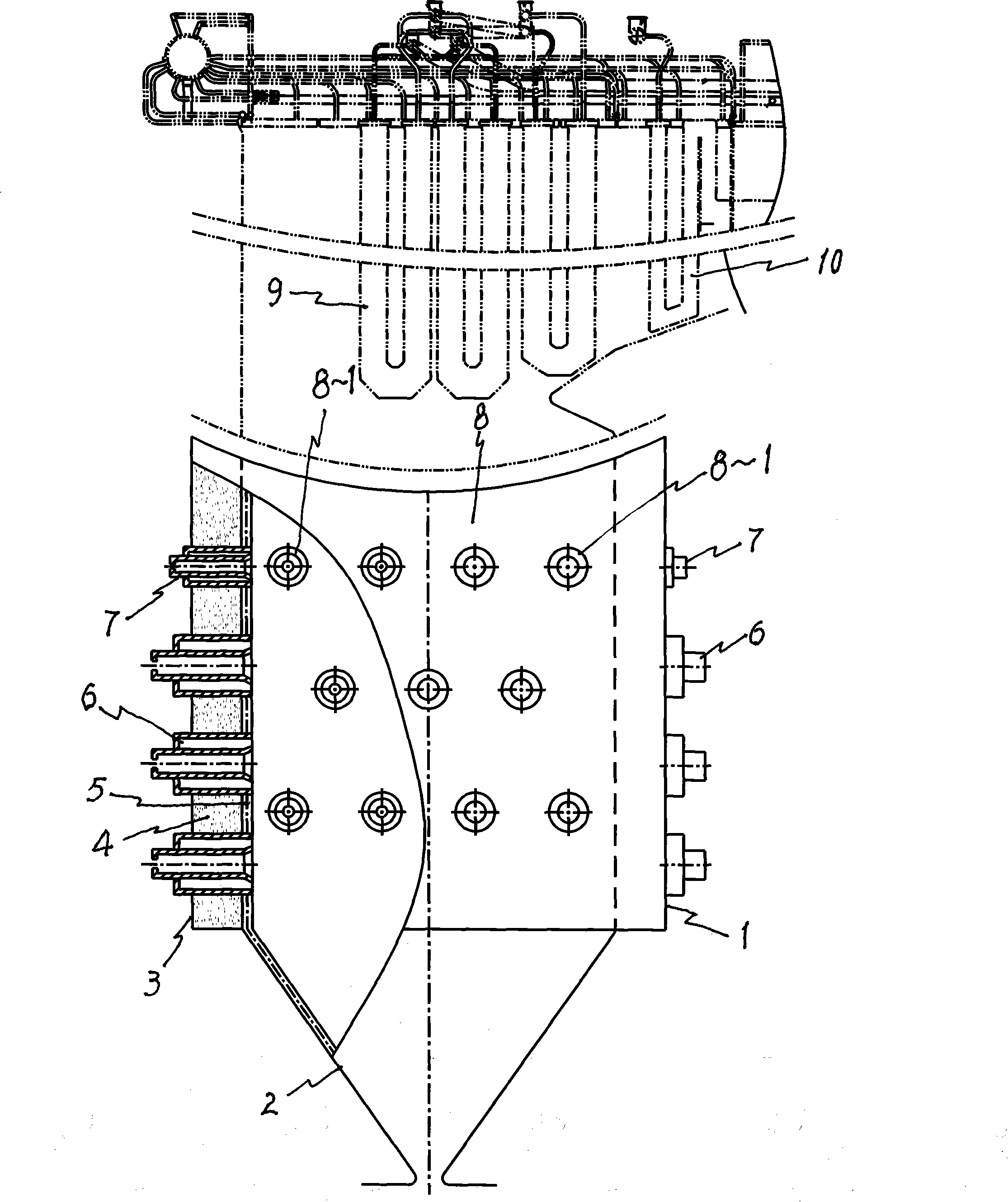

[0010] Example 1: Take the 600MW subcritical front and rear wall opposed combustion boiler furnace as an example: the structure of the furnace inner cavity, the front and rear walls 3, 1 and the cold ash hopper 2 are the same as the original boiler furnace, that is, the inner cavity width of the furnace is 20.7m , Depth (width of side wall water wall) 16.7m, the pipe diameter of furnace water wall 5 is φ66.7mm; 3 rows are symmetrically arranged on the front and rear walls 3 and 1, with 5 in each row (30 in total) pulverized coal Burner 6, each row is separated by 3.8m, each burner is horizontally separated by 3.68m; and each row is provided with 5 over-fired air burners at a distance of 3.8m from the upper pulverized coal burner axis section ( Group) 7, the distance between each is also 3.68m. In this embodiment, three rows of air nozzles 8 to 1 are arranged on the walls 8 on both sides. The uppermost row is arranged at the intersection of the axial section of the overfire air ...

Embodiment 2

[0011] Embodiment 2: In this embodiment, a row of 5 air nozzles 8 to 1 is set at the position 5.0m above the intersection of the pulverized coal burner shaft section and the side walls at the lower part of the furnace, the middle one is set on the central axis of the side wall, left , Two symmetrical on the right, the distance between each nozzle is 3.0m; the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com