Steam cracking method

A technology of steam and cracking furnace, applied in the field of steam cracking, which can solve problems such as olefin coking, and achieve the effects of increasing cracking products, slowing down coking and avoiding coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This example is used to illustrate the steam cracking method provided by the present invention.

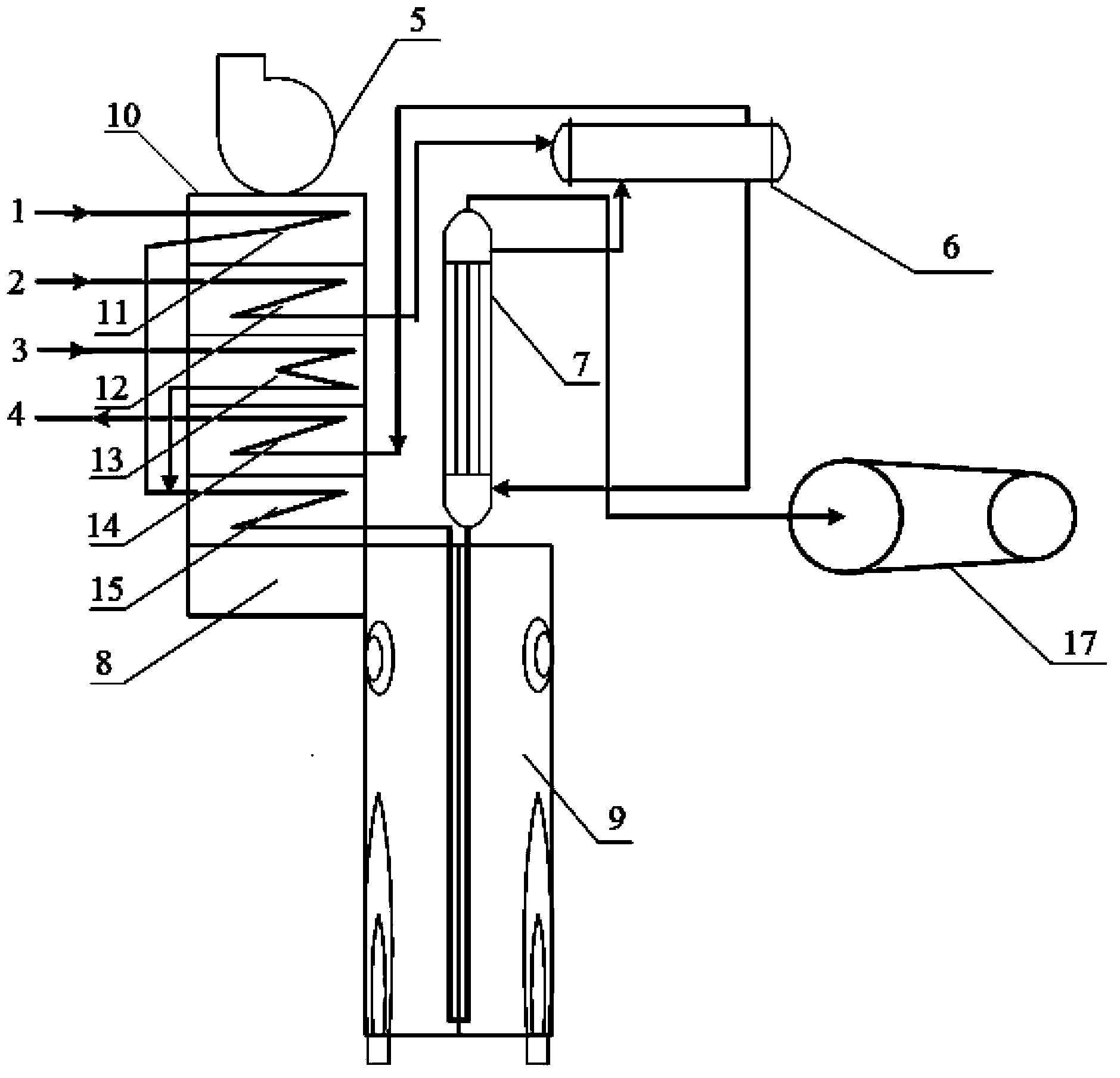

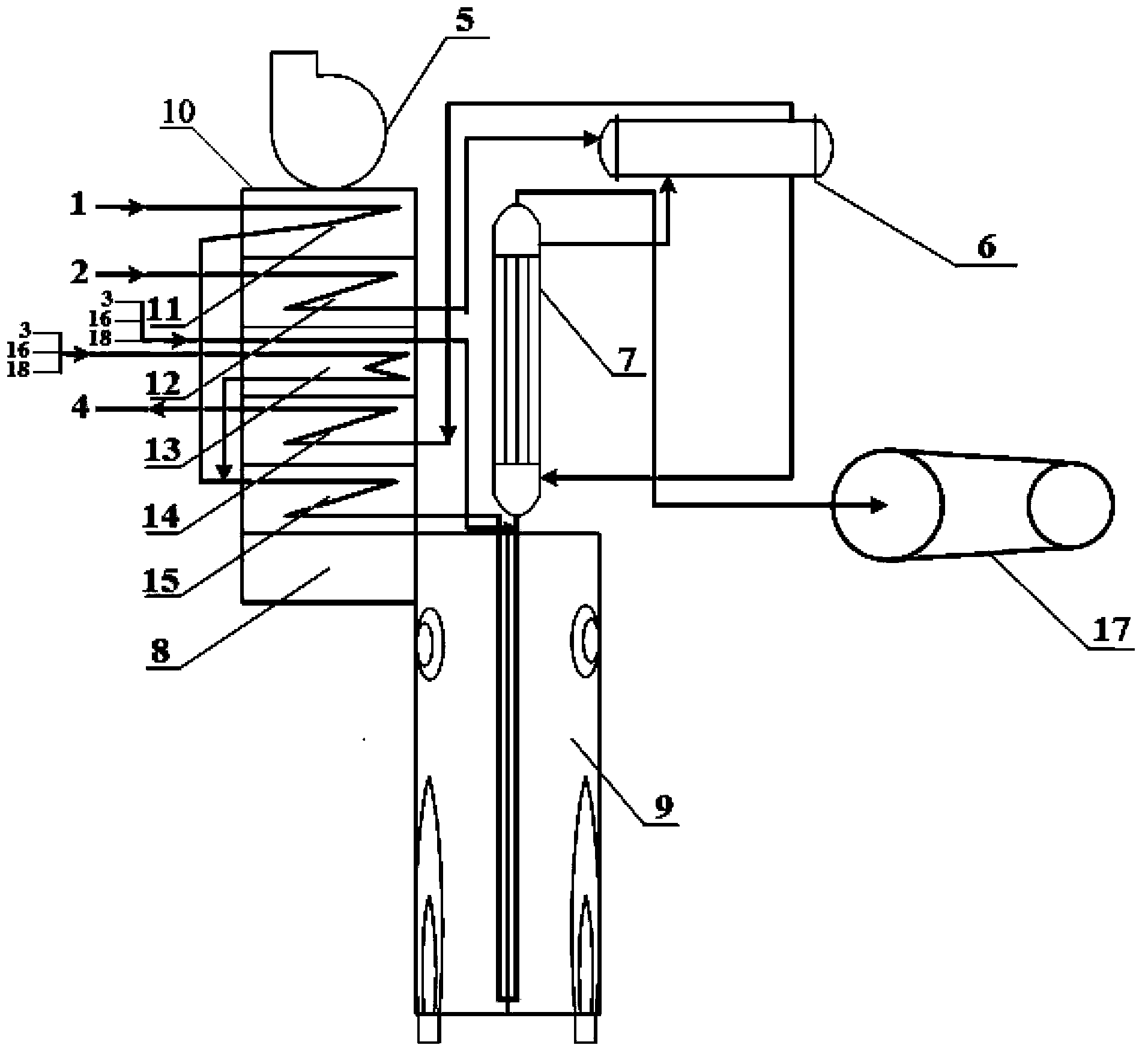

[0063] use figure 2 The cleavage apparatus shown performs the cleavage reaction. The specific process includes:

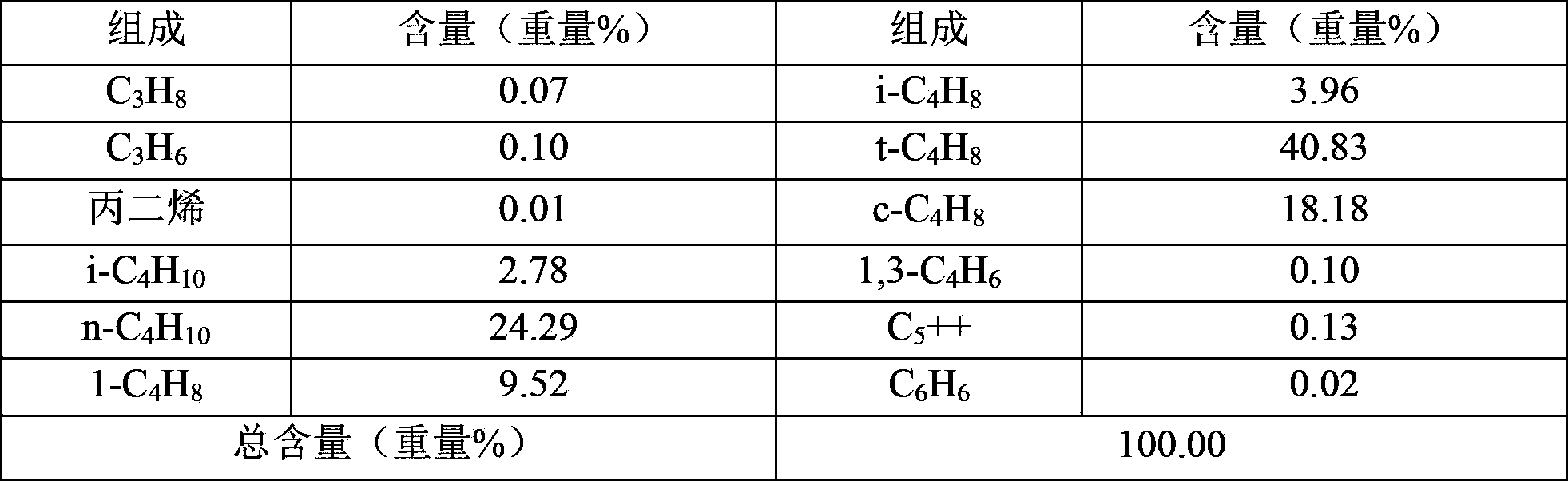

[0064] Naphtha 1 at 60°C (relevant parameters are shown in Table 2) is preheated through the raw material preheating section 11; at the same time, the mixed C4 olefins 16 (composition is shown in Table 1), hydrogen 18 and steam 3 are mixed to form The formed first stream is preheated through the dilution steam superheating section 13; then the preheated naphtha is mixed with the preheated first stream, and the obtained cracking raw material mixture is heated through the mixing heating section 15 , and then enter the radiant section 9 to carry out the cracking reaction; at the same time, the second stream (that is, the stream containing olefins) formed by mixing C4 olefins 16 (the composition is shown in Table 1), hydrogen 18 and water vapor 3 Preheating thro...

Embodiment 2

[0084] This example is used to illustrate the steam cracking method provided by the present invention.

[0085] Carry out steam cracking according to the method for embodiment 1, difference is, the feed intake of naphtha is 45400kg / h, and in the first stream, the injection rate of steam is 22700kg / h, and the feed intake of mixed C4 olefins is 1362kg / h, the injection rate of hydrogen is 15kg / h; in the second stream, the injection rate of water vapor is 2270kg / h, the feed rate of mixed C4 olefins is 2270kg / h, and the injection rate of hydrogen is 25kg / h, The temperature of the preheated second stream is 540°C, the temperature of the preheated second stream is 560°C, the crossover temperature is 590°C, the outlet temperature (COT) of the radiant section 9 is 830°C, and the radiant section The cleavage reaction time in 9 is 0.3 seconds. Other process parameters of the cracking furnace and the quenching heat exchange device 7 are shown in Table 7, and the composition of the cracke...

Embodiment 3

[0091] This example is used to illustrate the steam cracking method provided by the present invention.

[0092] Steam cracking is carried out according to the method of Example 1, the difference is that no steam 3 and hydrogen 18 are injected into the second stream (that is, the stream is composed of the mixed C4 olefins), and the second stream is passed through The convection section 10 is preheated to 200° C. and injected into the outlet of the radiant section 9 . Other process parameters of the cracking furnace and the quenching heat exchange device 7 are shown in Table 9, and the composition of the cracked gas is shown in Table 10 through separation and analysis of the cracked gas.

[0093] Table 9

[0094]

[0095] Table 10

[0096] components

[0097]By comparing Table 3 with Table 9 and Table 4 with Table 10, it can be seen that according to the method provided by the present invention, by injecting a mixture of olefins, hydrogen and water vapor as an ole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com