Method for efficiently extracting okra polysaccharide

A polysaccharide and high-efficiency technology, applied in the field of extracting okra polysaccharide, can solve problems such as low extraction rate of okra polysaccharide, and achieve the effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

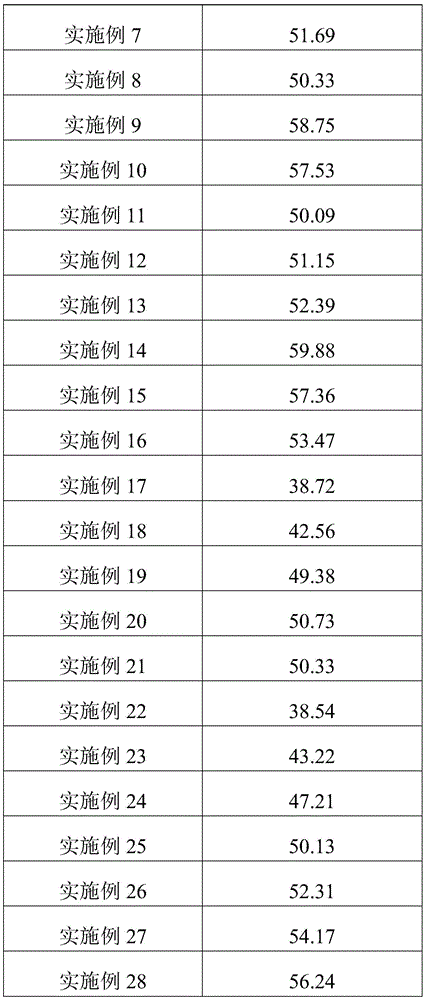

Embodiment 1-5

[0044] The method for efficiently extracting okra polysaccharide described in embodiment 1-5, comprises the steps:

[0045] (1) Grind red okra to powder, accurately weigh 10 g of red okra powder, add 650 mL of buffer solution of pH 5.0 prepared according to the above method and mix evenly, and perform ultrasonic extraction for 15 minutes under 140W power ultrasonic assisted conditions;

[0046] (2) Add the compound enzyme that comprises cellulase, pectinase and bovine trypsin in the feed liquid after ultrasonic treatment (in embodiment 1-5, the mass ratio of described cellulase, pectinase and bovine trypsin is respectively 2:2:1, 1:1:0.5, 1:3:2, 3:1:0.5, 3:1:2) mixing, the amount of the compound enzyme accounts for 2.25wt% of the feed liquid quality , and placed in a 60°C water bath for extraction for 2 hours;

[0047] (3) adding boiling water for enzyme inactivation treatment for 15 minutes, and then centrifuging to obtain the supernatant to obtain the crude extract containi...

Embodiment 6-10

[0049] The method for efficiently extracting okra polysaccharide described in embodiment 6-10, comprises the steps:

[0050](1) Get the red okra and grind it to powder, and accurately weigh 10g of the red okra powder, add the buffer solution of pH5. 400mL, 500mL, 600mL, 700mL) and mix well, and perform ultrasonic extraction for 15min under the condition of 180W power ultrasonic assist;

[0051] (2) Add a compound enzyme comprising cellulase, pectinase and bovine trypsin (the mass ratio of the cellulase, pectinase and bovine trypsin is 2:2:1) to the feed liquid after ultrasonic treatment Evenly, the consumption of described complex enzyme accounts for 2wt% of described feed liquid quality, and is placed in 60 ℃ of water-baths, water-bath extracts 30min;

[0052] (3) adding boiling water for enzyme inactivation treatment for 15 minutes, and then centrifuging to obtain the supernatant to obtain the crude extract containing the okra polysaccharide.

Embodiment 11-16

[0054] The method for efficiently extracting okra polysaccharide described in embodiment 11-16, comprises the steps:

[0055] (1) Get okra and grind it to powder, and accurately weigh 10g of okra powder, add 600mL of buffer solution 600mL of pH5. Ultrasonic frequency is 80W, 100W, 120W, 140W, 160W, 180W) for ultrasonic extraction for 15min;

[0056] (2) Add a compound enzyme comprising cellulase, pectinase and bovine trypsin (the mass ratio of the cellulase, pectinase and bovine trypsin is 2:2:1) to the feed liquid after ultrasonic treatment Evenly, the consumption of described complex enzyme accounts for 2wt% of described feed liquid quality, and is placed in 60 ℃ of water-baths, water-bath extracts 30min;

[0057] (3) adding boiling water for enzyme inactivation treatment for 15 minutes, and then centrifuging to obtain the supernatant to obtain the crude extract containing the okra polysaccharide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com