Aluminum alloy grain refiner and preparation method thereof

A technology of grain refiner and aluminum alloy, which is applied in the field of metal materials and metal material processing, can solve the problems of poor wettability, unsatisfactory anti-fading performance, and influence on the effect of grain refinement, and achieve short production process , good industrial application prospects, and the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

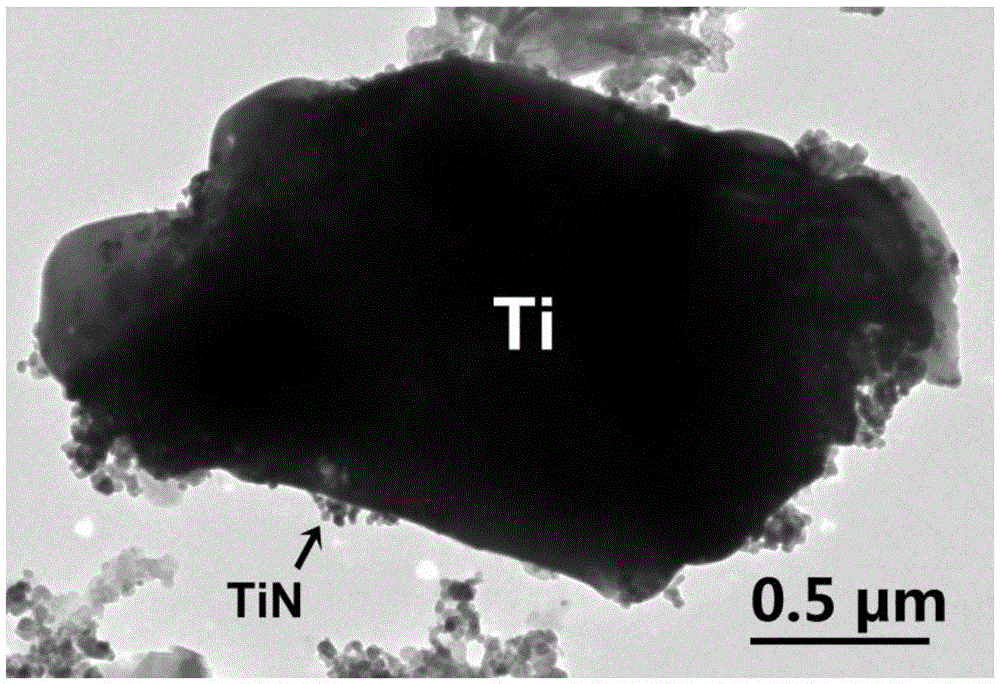

[0023] The 30nm TiN powder and the 10μm Ti powder were prepared into powder by mass fraction of 1:1, and the mixed powder was placed in a ball mill, and the Φ10mm ball was used for continuous one-way ball milling for 40 minutes to obtain grain refinement. agent.

Embodiment 2

[0025] The 50nm TiN powder and the 30μm Ti powder are prepared into powder by mass fraction of 1:50, and the mixed powder is put into a ball mill, and the Φ8mm ball is used for continuous one-way ball milling for 60 minutes to obtain grain refinement. agent.

Embodiment 3

[0027] 50nm TiN powder and 30μm Ti powder were prepared into powder by mass fraction of 1:20, and the mixed powder was placed in a ball mill, and Φ8mm balls were used for continuous one-way ball milling for 20 minutes to obtain grain refinement. agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com