Modified NASICON type oxide ceramic electrolyte as well as preparation method and application thereof

An oxide ceramic and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of poor cycle performance of solid-state metal batteries, complex interface contact states, and large interface contact resistance, and improve interface compatibility. The effect of improving the carrier transport ability and suppressing the crack extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

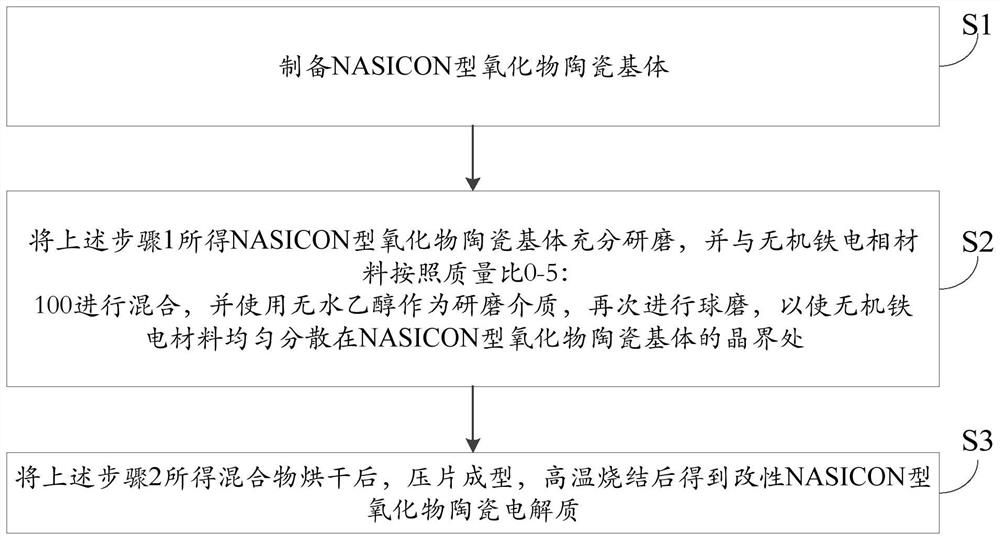

[0069] Prepare NASICON type oxide ceramic electrolyte, the NASICON type ceramic electrolyte is Na 1+x Zr 2 Si x P 3- x o 12 , where x=2:

[0070] (1) Weigh 0.03molNa 2 CO 3 , 0.02molZrN 2 o 7 (zirconyl nitrate), 0.02molSiO 2 with 0.01molNH 4 h 2 PO 4 , add ethanol ball mill for 12h, rotating speed 300r·min -1 , after uniform ball milling, discharging and drying;

[0071] (2) Put the mixture described in step (1) in a muffle furnace, raise the temperature to 1000°C, keep it warm for 6h, and the heating rate is 3°C·min -1 , cooled to room temperature to obtain a pre-sintered block;

[0072] (3) The pre-sintered block obtained in step (2) is subjected to secondary ball milling, discharging, and after drying, the pre-sintered powder is placed in an agate mortar and the mass fraction is 5% PVA aqueous solution, after fully grinding dry;

[0073] (4) Compressing the powder obtained in step (3) into tablets under a pressure of 10MPa, wherein the holding time is 10s; ...

Embodiment 2

[0077] Prepare modified NASICON type oxide ceramic electrolyte, the NASICON type ceramic matrix is Na 1+x Zr 2 Si x P 3- x o 12 , where x=2; add BaTiO with a mass ratio of 3% 3 modified:

[0078] (1) Weigh 0.03molNa 2 CO 3 , 0.02molZrN 2 o 7 (zirconyl nitrate), 0.02molSiO 2 with 0.01molNH 4 h 2 PO 4 , add ethanol ball mill for 12h, rotating speed 300r·min -1 , after uniform ball milling, discharging and drying;

[0079] (2) Put the mixture described in step (1) in a muffle furnace, raise the temperature to 1000°C, keep it warm for 6h, and the heating rate is 3°C·min -1 , cooled to room temperature to obtain a pre-sintered block;

[0080] (3) The pre-sintered powder obtained in step (2) and its mass ratio are 3% commercially obtained BaTiO 3 The powder is evenly mixed for ball milling, discharged, and after drying, put in an agate mortar and add an aqueous solution of PVA with a mass fraction of 5%, fully grind and then dry;

[0081] (4) Compressing the powd...

Embodiment 3

[0085] Preparation of modified NASICON-type oxide ceramic electrolyte, the NASICON-type ceramic matrix is Li 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 ; Add mass ratio of 3% (K,Na)NbO 3 modified:

[0086] (1) Weigh 0.013molLi 2 CO 3 , 0.003molAl(NO 3 ) 3 , 0.017molTiO 2 with 0.03molNH 4 h 2 PO 4 , add ethanol ball mill for 12h, rotating speed 300r·min -1 , after uniform ball milling, discharging and drying;

[0087] (2) Put the mixture described in step (1) in a muffle furnace, raise the temperature to 800°C, keep it warm for 6h, and the heating rate is 3°C·min -1 , cooled to room temperature;

[0088] (3) The pre-sintered powder obtained in step (2) and its mass ratio are 3% (K, Na) NbO 3 The inorganic ferroelectric phase material is ball milled, discharged, dried, placed in an agate mortar and added with a 5% PVA aqueous solution, fully ground and dried;

[0089] (4) Compressing the powder obtained in step (3) into tablets under a pressure of 10MPa, wherein the holding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com