A kind of injection molding plastic and soft magnetic powder composite material and preparation method thereof

A composite material and injection molding technology, which is applied in the fields of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve problems such as the difficulty in preparing soft magnetic materials with high powder content and three-dimensional structure, and improve interface compatibility problem, increase fill rate, increase compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] And, the embodiment of the present invention also provides a preparation method of injection molding plastic and soft magnetic powder composite material, comprising the following steps:

[0034] S01. Weigh each component according to the formula of the above-mentioned injection molding plastic and soft magnetic powder composite material;

[0035] S02. dissolving the coupling agent in a solvent to form a coupling agent solvent;

[0036] S03. After mixing the soft magnetic powder with the coupling agent solvent, heat treatment is performed to obtain a soft magnetic powder coating;

[0037] S04. Perform banburying and mixing treatment on the soft magnetic powder coating body, high fluidity plastics, plasticizer, and antioxidant to obtain a rubber compound;

[0038] S05. Extrude and granulate the mixed rubber after crushing.

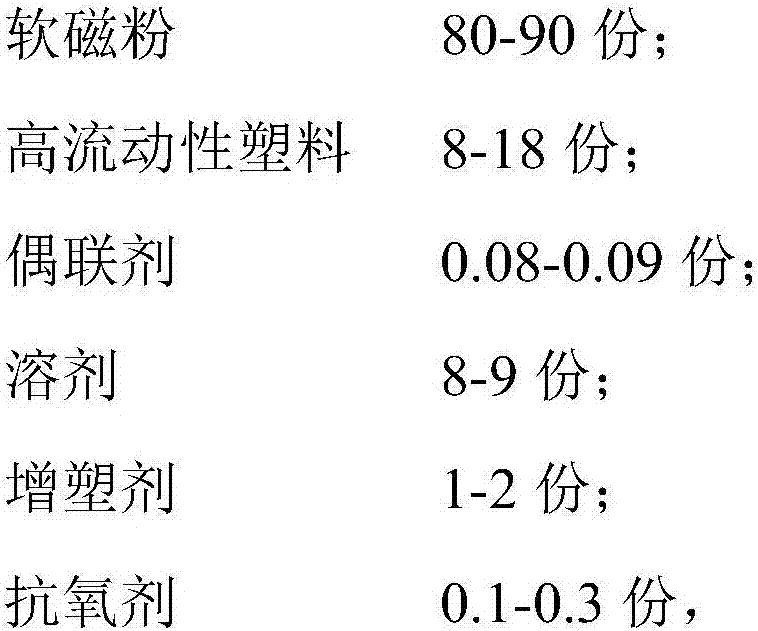

[0039] In the above step S01, the formulation components of the injection-molded plastic and soft magnetic powder composite material and their pref...

Embodiment 1

[0048] An injection molding plastic and soft magnetic powder composite material, comprising the following components in the following parts by weight:

[0049]

[0050] In the composite material, the soft magnetic powder is coated with a coupling agent solvent to form a soft magnetic powder coating body,

[0051] Wherein, the soft magnetic powder is manganese zinc ferrite magnetic powder, the high fluidity plastic is polyphenylene sulfide; the coupling agent is a silane coupling agent, the solvent is deionized water, and the plasticizer It is epoxidized soybean oil, and the antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine.

[0052] The preparation method of the injection molding plastic and soft magnetic powder composite material comprises the following steps:

[0053] S11. Mix and stir 0.08 parts by mass of silane coupling agent and 8 parts of deionized water at room temperature to form a solution;

[0054] S12. Stir and mix th...

Embodiment 2

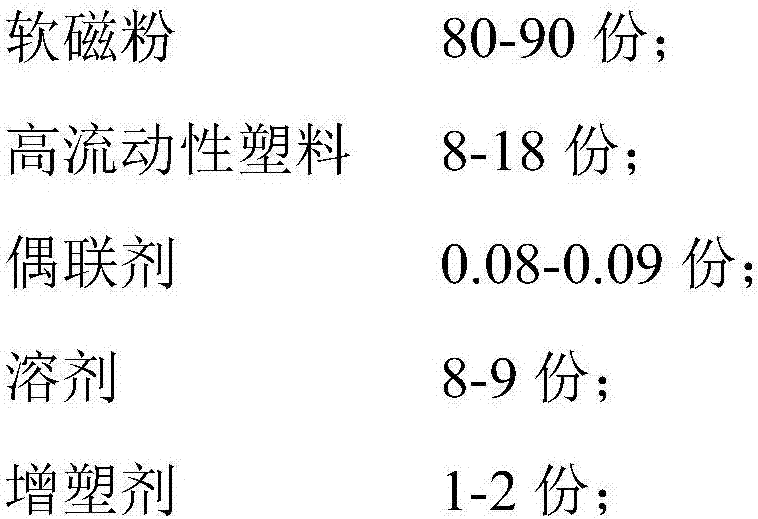

[0060] An injection molding plastic and soft magnetic powder composite material, comprising the following components in the following parts by weight:

[0061]

[0062] In the composite material, the soft magnetic powder is coated with a coupling agent solvent to form a soft magnetic powder coating body,

[0063] Wherein, the soft magnetic powder is sendust magnetic powder, the high fluidity plastic is nylon; the coupling agent is a silane coupling agent, the solvent is deionized water, and the plasticizer is epoxy soybean oil , the antioxidant is N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionyl) hexamethylenediamine.

[0064] The preparation method of the injection molding plastic and soft magnetic powder composite material comprises the following steps:

[0065] S21. Mix and stir 0.09 parts by mass of silane coupling agent and 9 parts of deionized water at room temperature to form a solution;

[0066] S22. The solution prepared in step 1 is stirred and mixed wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com