Low-temperature plug valve

A plug valve, low temperature technology, applied in the field of plug valves, can solve the problems of unqualified materials, external leakage or internal leakage of the shell and sealing surface, and can not meet the requirements of use, and achieves strength and rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

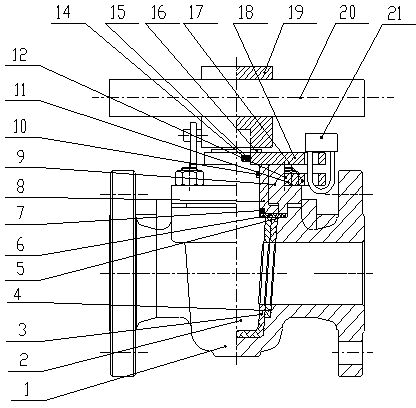

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

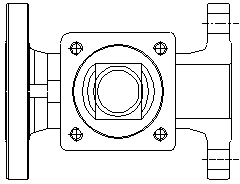

[0023] Such as figure 1 As shown, the embodiment of the present invention includes a valve body 1, a cock 2, a cock sleeve 3, a valve body bushing 4, a spiral wound gasket 5, a diaphragm 6, a spiral wound gasket 7, a stuffing box 8, a valve cover 9, and an O-ring 10 , Stud 11, nut 12, antistatic spring 14, steel ball 15, circlip 16, fixed block 17, positioning piece 18, handle seat 19, handle 20, lock 21.

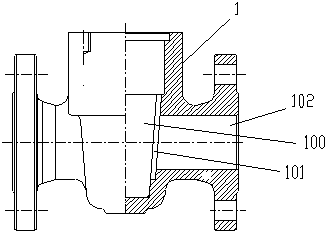

[0024] Specifically, as figure 1 , Figure 2-Figure 4 The valve body 1 includes a cavity 100 in the central area and a channel 102 for passing the medium. The side wall of the cavity 100 is provided with an annular groove 101 , and the valve body bushing 4 is embedded in the annular groove 101 . And the material of the valve body 1 is LCB (LCB cast steel grade, a low-temperature carbon steel of American standard), LC3 (Al-Zn-Mg-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com