Assembled cable saddle structure for suspension bridge

A technology of assembled and suspension bridges, applied in the directions of suspension bridges, bridge forms, bridges, etc., can solve the problems of large transportation and hoisting difficulties, single block volume, large weight, difficult control of mechanical processing, etc., and achieves low requirements for transportation and hoisting equipment. , Simple processing, flexible assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

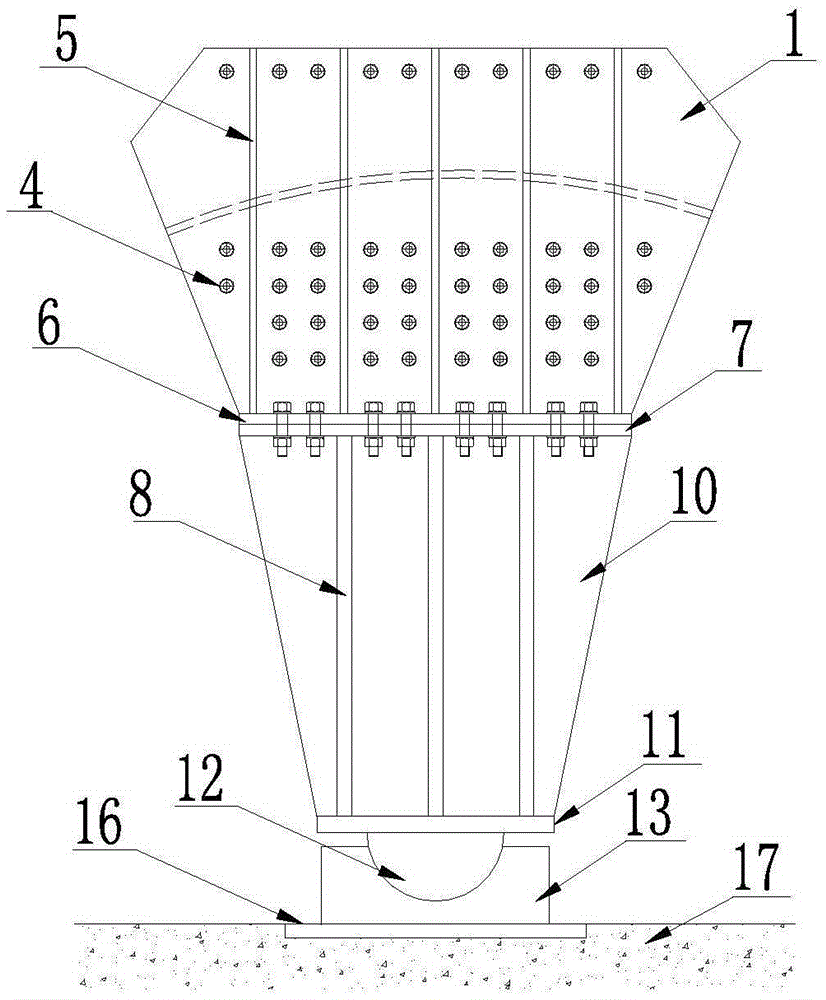

[0034] Such as Figure 1 ~ Figure 3 As shown in the figure, a new type of loose cable saddle structure is formed by welding the side plate 1 and the transverse rib plate 5 to form a side plate, which is connected with the saddle support plate 2 and the partition plate 3 through high-strength bolts 4 to form a saddle groove. The parts are processed and formed according to the requirements, wherein the partition becomes thicker in the longitudinal direction, the side plate is tightly connected to the saddle bottom plate 6 and the transverse rib 5 is welded to the saddle bottom plate to enhance the stability of the steel plate. Bolting or welding is used to connect the groove base 13 to the foundation backing plate 16, so as to achieve consolidation with the foundation 17, and the upper bearing plate 7, the longitudinal plate 10, the middle transverse plate 9, the side transverse plate 8, and the lower base plate are welded. 11 and the rotating shaft 12 are connected into one bod...

Embodiment 2

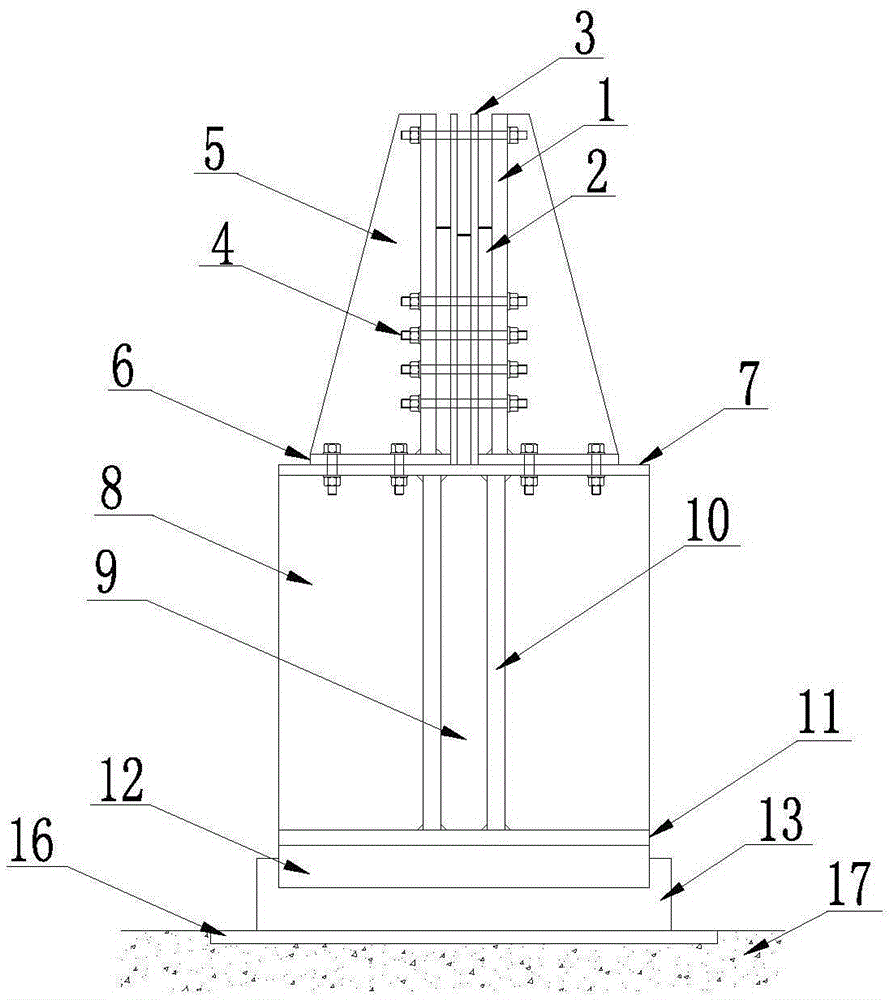

[0036] Such as Figure 4 As shown in Fig. 1, another new type of loose cable saddle structure is formed by welding the side plate 1 and the transverse rib plate 5 to form a side plate, which is connected with the saddle support plate and the partition plate through high-strength bolts 4 to form a saddle groove. It is processed and formed according to the requirements, wherein the partition plate becomes thicker in the longitudinal direction, the side plate and the saddle bottom plate 6 are tightly pressed and the transverse rib 5 is welded to the saddle bottom plate to enhance the stability of the steel plate. The upper support plate 7, the longitudinal plate 10, the middle transverse plate, the side transverse plate 8, and the lower base plate 11 are welded to form a seat body, and a sliding shaft 14 is arranged between the lower base plate 11 of the seat body and the foundation backing plate 16 to realize the seat body. For longitudinal displacement requirements, the sliding...

Embodiment 3

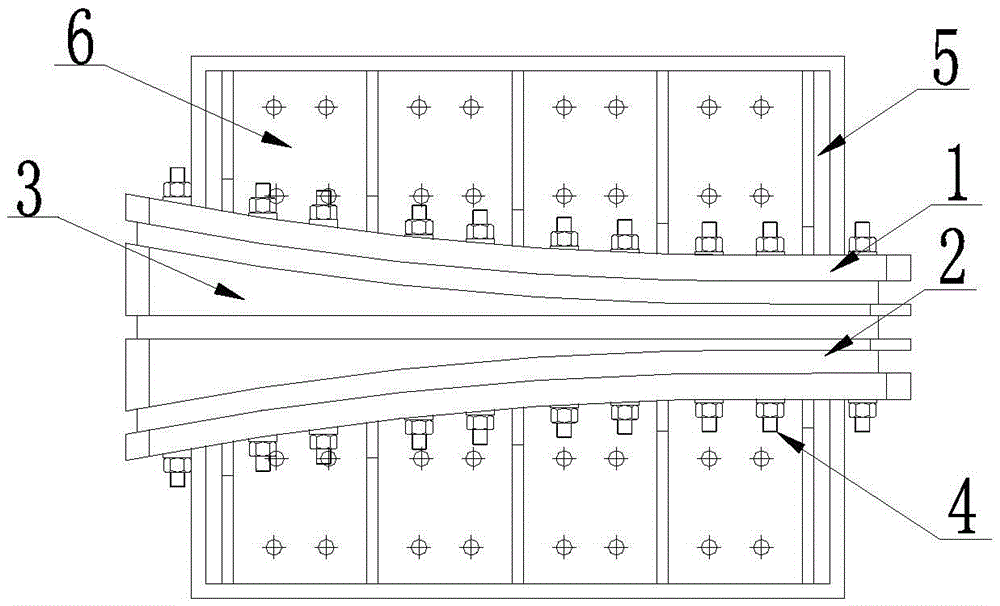

[0038] Such as Figure 5 ~ Figure 7As shown, a new assembled main cable saddle structure, the side plate is welded by the side plate 1 and the transverse rib plate 5 and connected with the saddle support plate 2 and the partition plate 3 through high-strength bolts 4 to form a saddle groove, the partition plate The thickness is equal in the longitudinal direction, the side plate is pressed against the saddle bottom plate 6 and the transverse rib 5 is welded to the saddle bottom plate to enhance the stability of the steel plate. The upper bearing plate 7, the longitudinal plate 10, the middle horizontal plate 9, the side horizontal plate 8, and the lower bottom plate 11 are connected into a seat body by welding, and a pushing sliding friction pair 19 is set between the lower bottom plate 11 of the seat body and the foundation backing plate 16, In order to realize the deviation requirement of the saddle during the construction stage, after the work of pushing the saddle is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com