Wall used in building

A technology for construction and walls, applied in the direction of buildings, building components, building structures, etc., can solve the problems of waterproof, moisture-proof, large manpower demand, poor thermal insulation and sound insulation, etc., and achieve good dryness and thermal insulation performance. The effect of reducing the demand for manpower and improving the load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

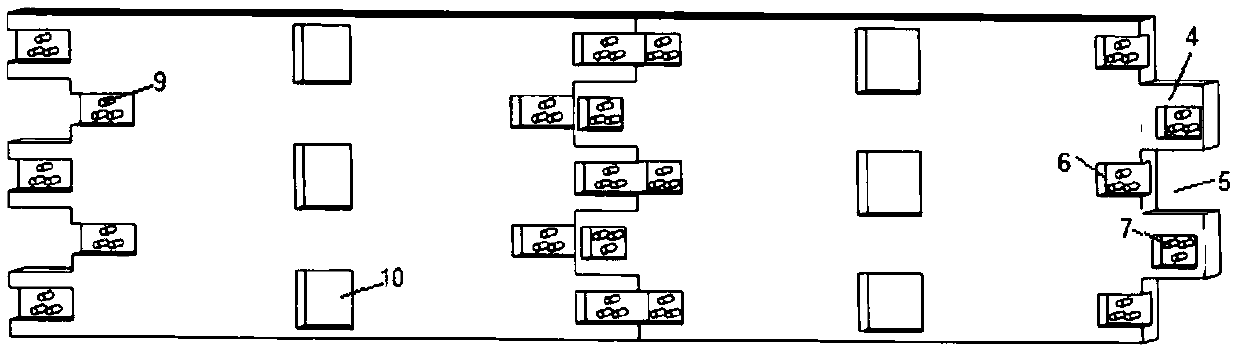

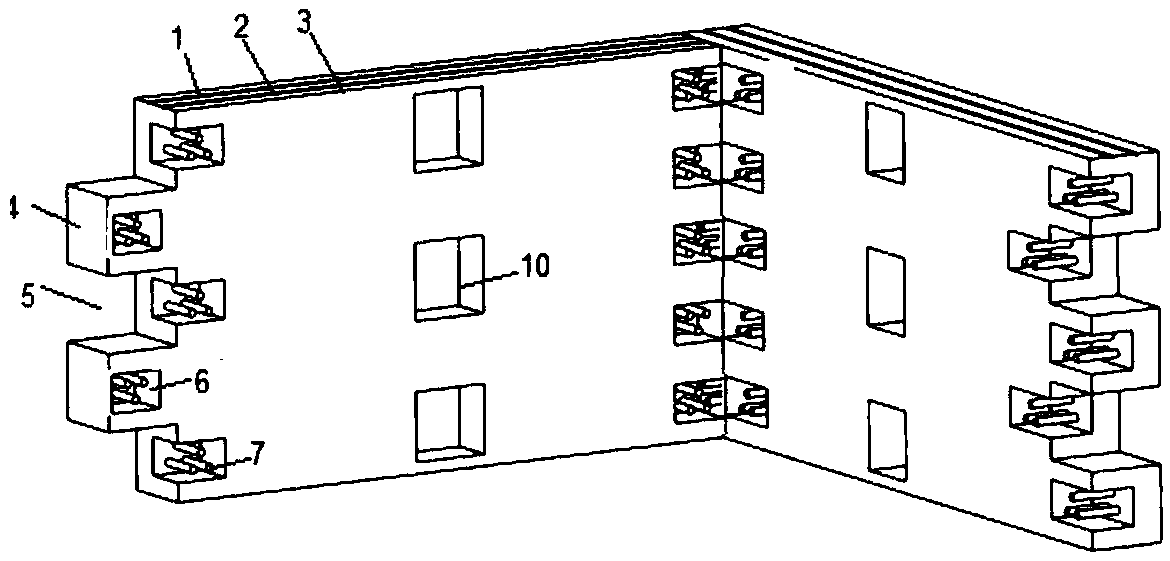

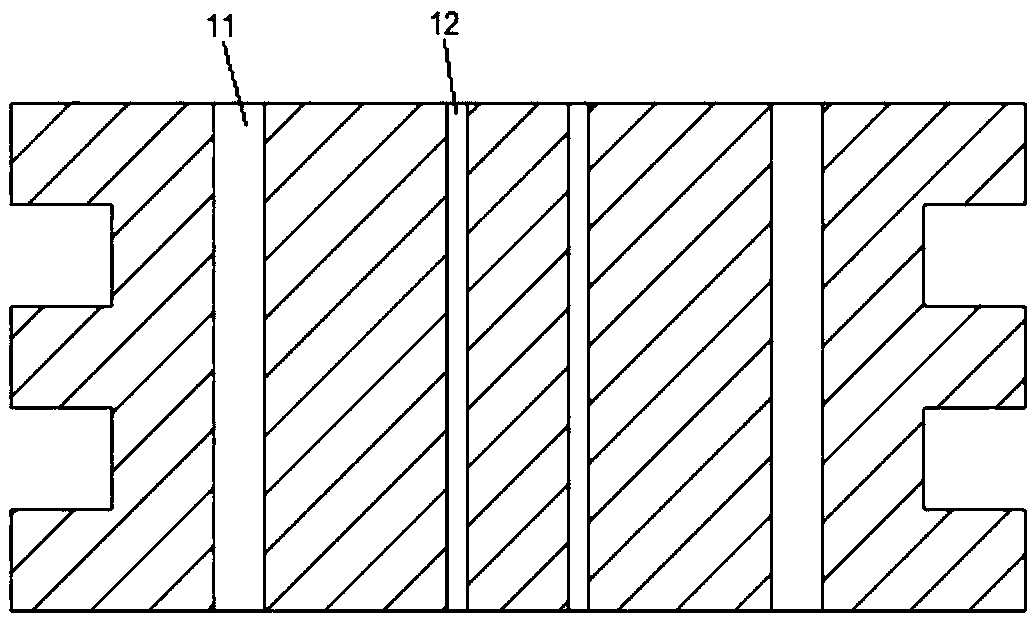

[0027] like Figure 1-3 As shown, the building wall of an embodiment of the present invention includes a plurality of wall panels, and the wall panels are composed of an outer wall panel 1, an insulation layer 2 and an inner wall panel 3; the end faces Y on both sides of the wall panels There are protrusions 4 and grooves I5 with matching shapes at intervals in the direction, and the wall panels are connected in parallel or vertically through matching protrusions 4 and grooves I5 to form a plane wall or a wall with a right angle; The surface of the side is provided with a groove Ⅱ6, and the connecting rod 7 that runs through the wallboard at the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap