An indirect test and alarm device for oxidation temperature of residual coal in goaf

A technology of oxidation temperature and goaf, which is applied in mining equipment, mining equipment, earthwork drilling and mining, etc., can solve the problems of signal transmission line breakage, low test reliability, and difficulty in testing magnetic anomalies and resistivity anomalies. Strong anti-interference ability, easy operation and simple principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

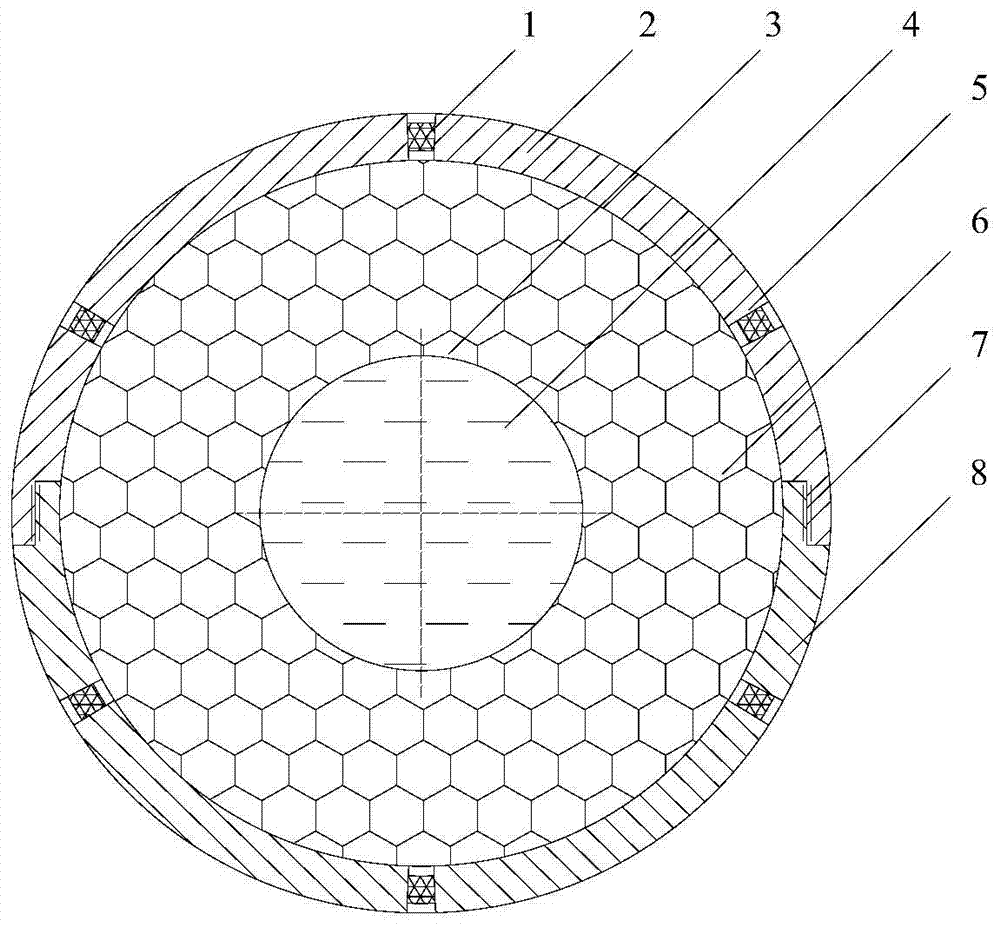

[0010] Such as figure 1 As shown in the figure, an indirect test and alarm device for the oxidation temperature of residual coal in the goaf mainly includes a small gas release hole 1, a high-strength steel ball in the upper half, a glass ball 3, a temperature-sensitive special odor liquid 4, a steel mesh 5, and a ventilating Buffer the lightweight interlayer 6 and the lower half of the high-strength steel ball 8; during the normal mining process of the coal mining face, the device is placed in the goaf from the gap between the fully mechanized mining supports as required, and as the working face advances, the device Gradually enter the oxidation zone from the heat dissipation zone; when the low-temperature oxidation occurs in the coal left in the goaf at the test site, and the temperature reaches the set temperature of the device, the volume expansion of the temperature-sensitive special odor liquid 4 in the device reaches a certain value, and the glass ball 3 is broken at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com