Energy saver for vertical natural circulation condensing boiler

A technology of natural circulation and condensing boilers, applied in steam boilers, water tube steam boilers, combustion methods, etc., can solve the problems of large footprint, corrosion, limited recovery effect, etc., to solve the problem of large footprint and reduce manufacturing costs , Solve the effect of excessive steel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

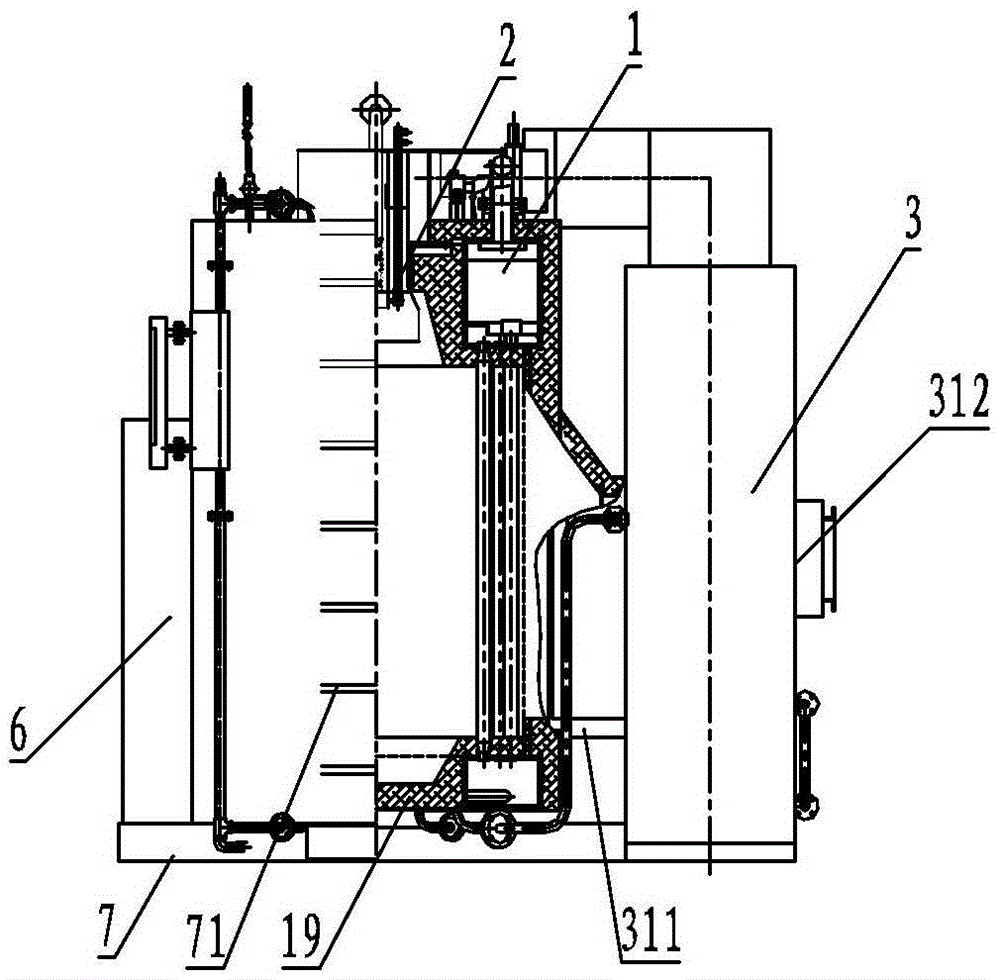

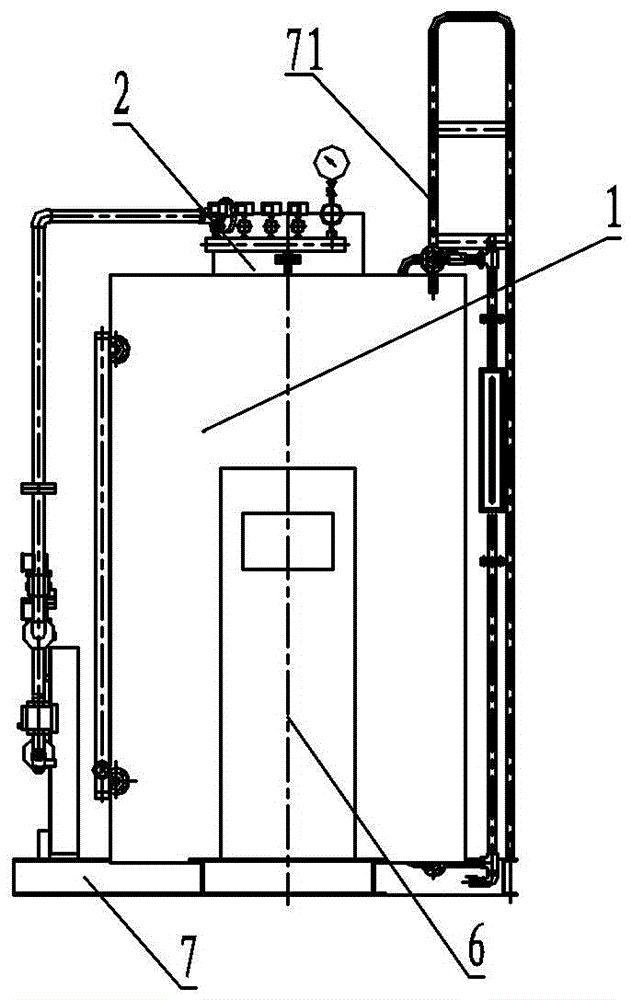

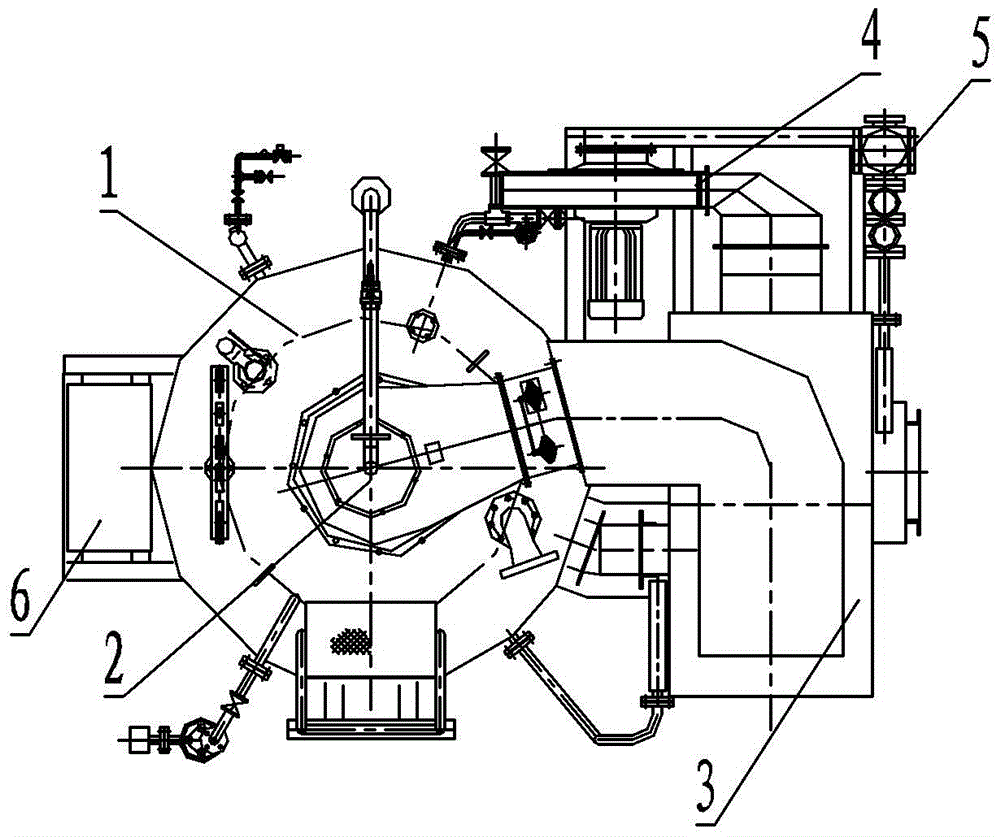

[0029] see figure 1 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

[0030] see figure 1 , a vertical natural circulation condensing boiler of the present invention includes a boiler body 1, and the boiler body 1 is divided into a furnace 11 and a flue gas chamber 12 arranged coaxially. A smoke outlet 13 is provided on the outer peripheral wall of the smoke cavity 12 . The upper and lower ends of the smoke chamber 12 are respectively provided with an upper annular header 16 and a lower annular header 17 . The upper annular header 16 and the lower annular header 17 communicate with each other through a centralized ascending tube bundle 14 and a concentrated descending tube bundle 15 . Among them, the centralized descending pipe bundle 15 is composed of a circle of concentrated descending pipes arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com