System for recycling uncondensed gases of alkylation compressor

A compressor and alkylation technology, applied in pipeline systems, incinerators, mechanical equipment, etc., can solve problems such as unfavorable economic benefits, waste of resources, and upgrading, and achieve the effect of improving economic benefits and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

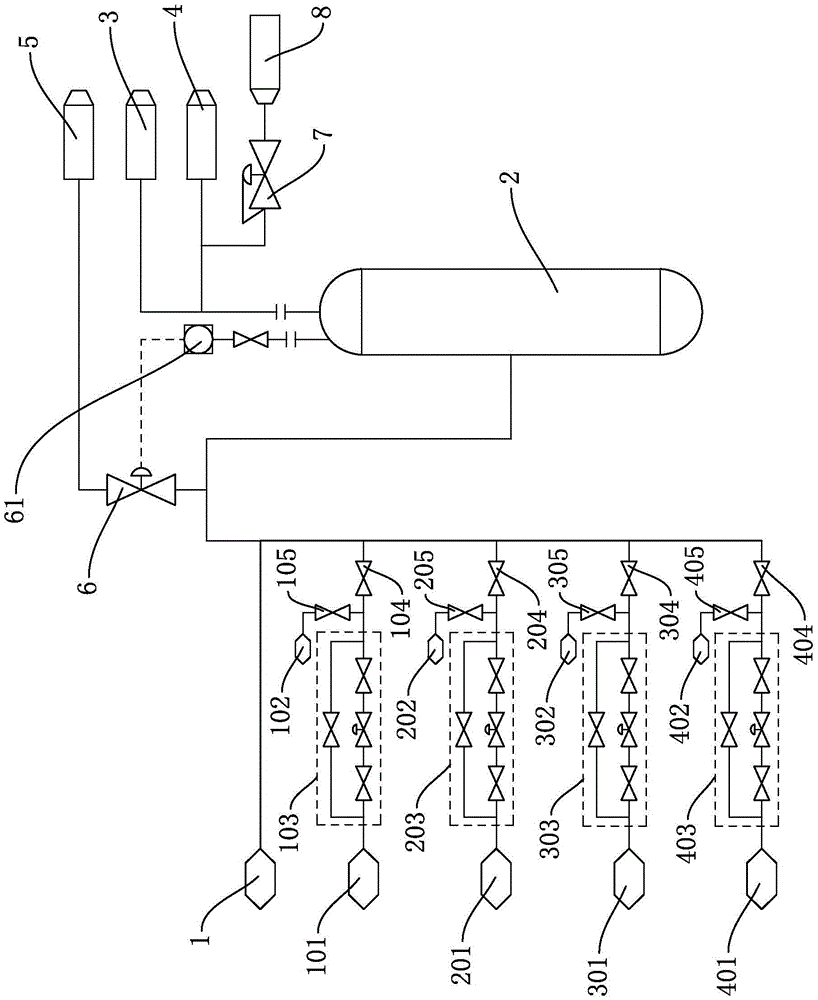

[0015] Such as figure 1 The shown alkylation compressor non-condensable gas recycling system includes compressor non-condensable gas outlet 1, fuel buffer tank 2, waste acid incinerator inlet 3, torch light inlet 4, the compressor The non-condensable gas outlet 1 communicates with the air inlet of the fuel buffer tank 2 , and the waste acid incinerator inlet 3 and the torch light inlet 4 communicate with the fuel buffer tank 2 air outlet.

[0016] It also includes a flare gas main pipe inlet 5, the flare gas main pipe inlet 5 communicates with the air inlet of the fuel buffer tank 2 through a pressure control valve 6, and the fuel buffer tank 2 is connected with a pressure control valve for controlling the pressure. 6 open and close pressure sensors 61.

[0017] The air inlet 4 of the torch light is communicated with a supplementary gas tank 8 through a self-operated regulating valve 7 .

[0018] It also includes a non-condensable gas outlet 101 of the light removal tower an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap