Dead zone compensating control method for mechanical arm servo system with guaranteed transient performance

A technology of servo system and control method, which is applied in the direction of adaptive control, general control system, control/regulation system, etc., and can solve problems such as the complexity explosion of the inversion method and the uncertainty of model parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

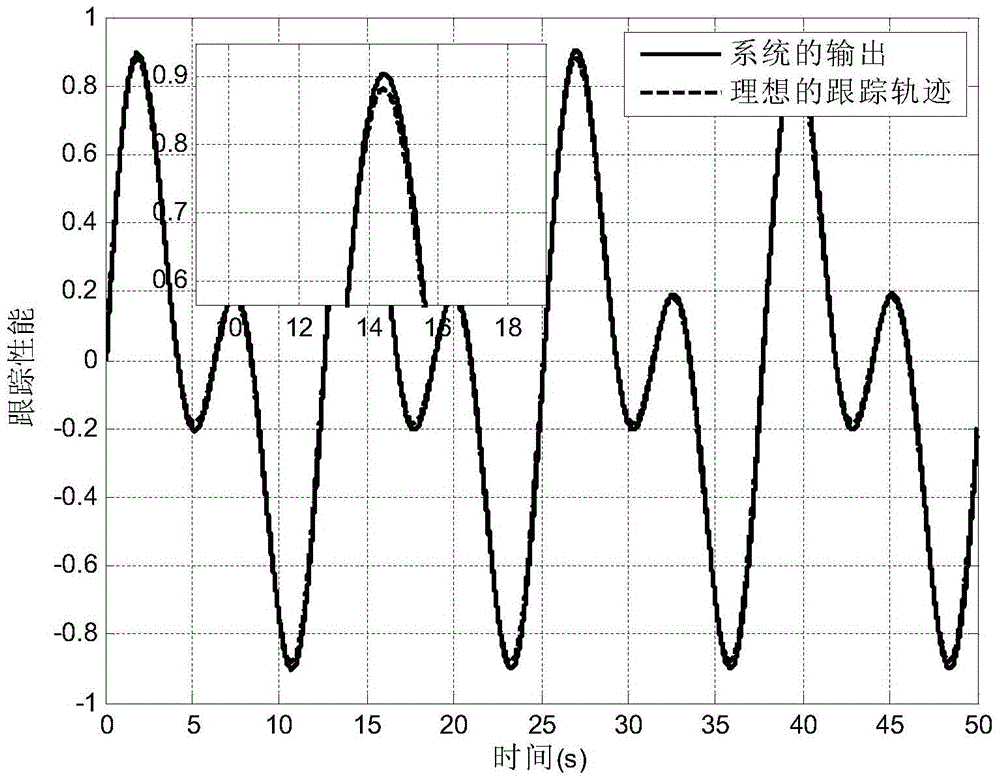

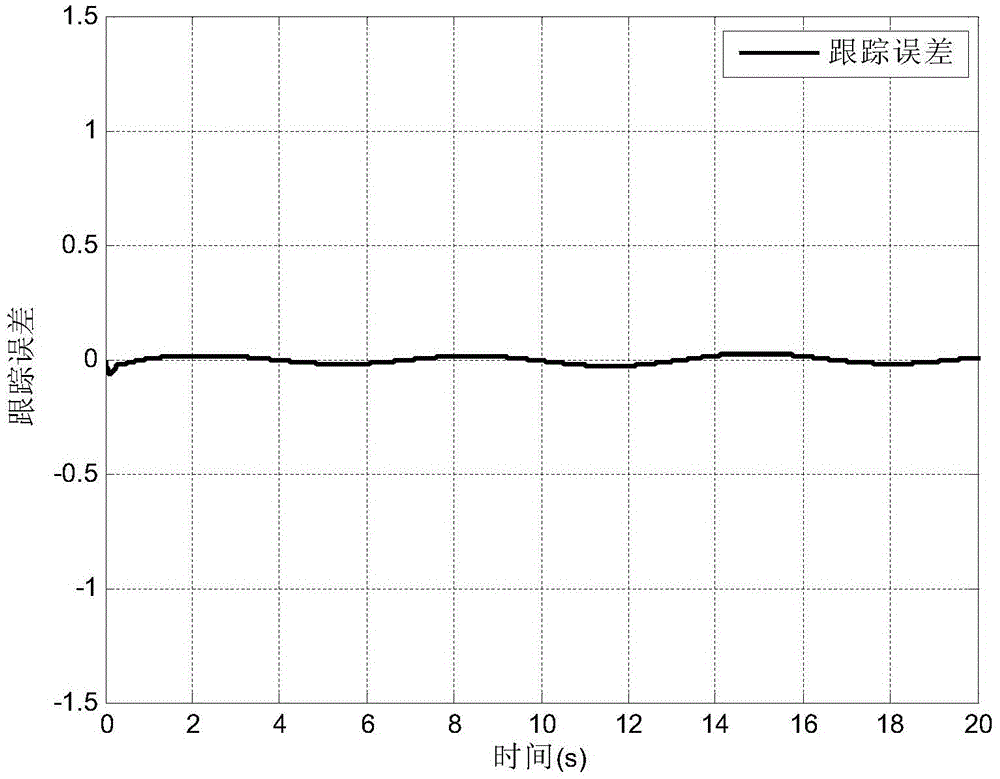

[0118] The present invention will be further described below in conjunction with the accompanying drawings.

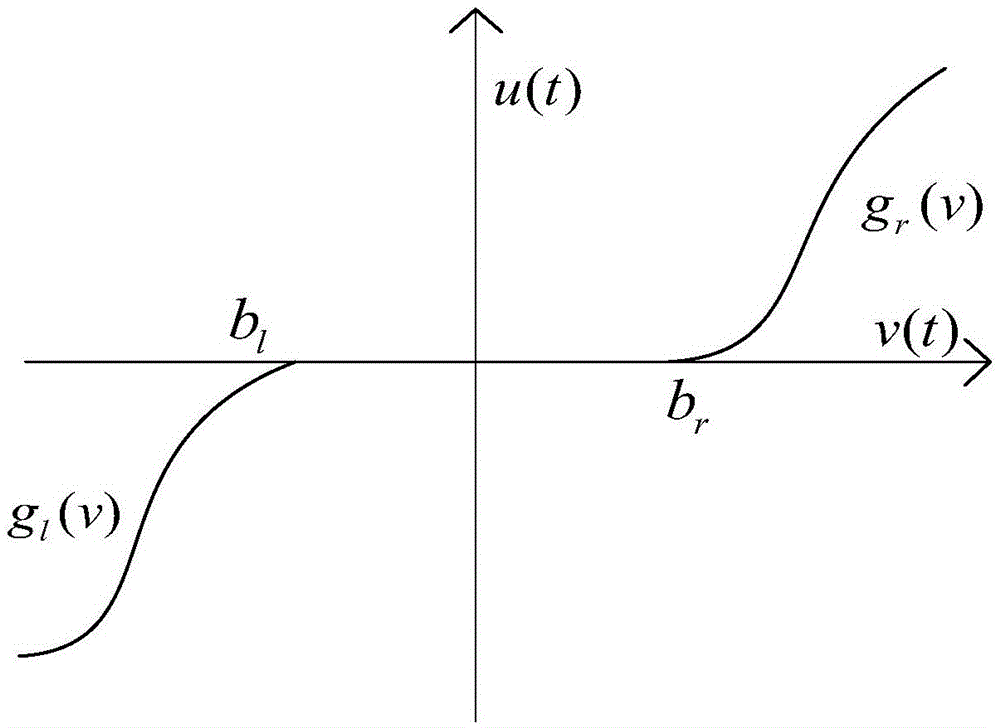

[0119] refer to Figure 1-Figure 5 , a dead zone compensation control method for a mechanical arm servo system that ensures transient performance, comprising the following steps:

[0120] Step 1, establish the dynamic model of the servo system of the manipulator, initialize the system state, sampling time and control parameters, the process is as follows:

[0121] 1.1 The expression form of the dynamic model of the manipulator servo system is

[0122] I q ·· + K ( q - θ ) + M ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com