Assembly whose inner circuit is optimized

A technology of internal circuits and components, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of high circuit loss, achieve the effect of increasing power output, reducing shading area, and optimizing internal circuits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

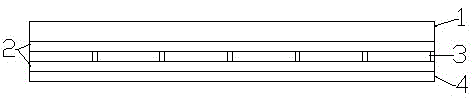

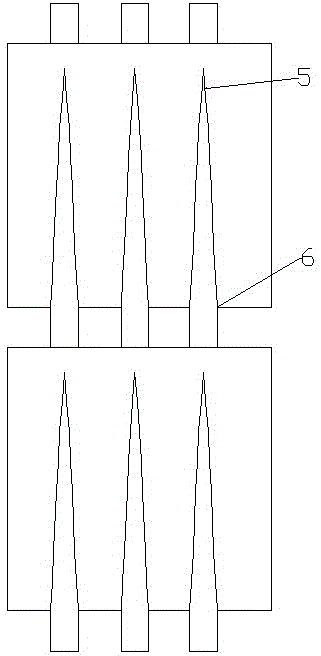

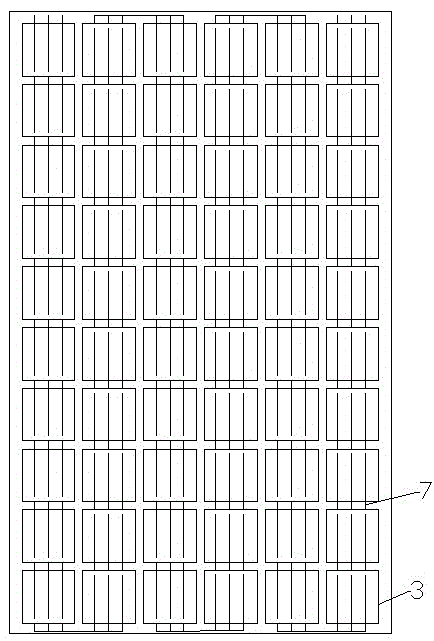

[0021] An assembly for optimizing the internal circuit of the present invention includes encapsulating glass 1, EVA2, battery sheet 3, EVA2, and backplane 4 from top to bottom, wherein the battery sheets 3 are connected in series through welding ribbons 7, and each welding ribbon 7. Connect the front of one cell 3 and the back of the next cell 3 in turn. The welding ribbon 7 on the front of the battery 3 is from the starting point 5 of the front welding ribbon to the end point 6 of the front welding ribbon. The width of the welding ribbon 7 gradually becomes wider; the battery sheet 3 The ribbon 7 on the back is from the starting point 8 of the ribbon on the back to the end point 9 of the ribbon on the back, and the width of the ribbon 7 gradually becomes wider. The position of the edge of sheet 3.

[0022] The width of the welding ribbon 7 between two adjacent battery sheets 3 connected in series remains unchanged.

[0023] The size of the module is 1640*992mm, the size of t...

Embodiment 2

[0025] An assembly for optimizing the internal circuit of the present invention includes encapsulating glass 1, EVA2, battery sheet 3, EVA2, and backplane 4 from top to bottom, wherein the battery sheets 3 are connected in series through welding ribbons 7, and each welding ribbon 7. Connect the front of one cell 3 and the back of the next cell 3 in turn. The soldering strip 7 on the front of the cell 3 is from the starting point 5 of the front soldering strap to the end point 6 of the front soldering strap. The width of the soldering strap 7 gradually becomes thicker; the cell 3 The ribbon 7 on the back is from the starting point 8 of the ribbon on the back to the end point 9 of the ribbon on the back, and the width of the ribbon 7 gradually becomes thicker. The position of the edge of sheet 3.

[0026] The thickness of the welding strip 7 between two adjacent battery sheets 3 connected in series remains unchanged.

[0027] The size of the module is 1640*992mm, the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com