Long-storage lifetime lithium-ion battery and treatment method therefor

A lithium-ion battery, storage life technology, applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of battery performance degradation, etc., to achieve the effect of reducing self-discharge rate, ensuring stability, and improving storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

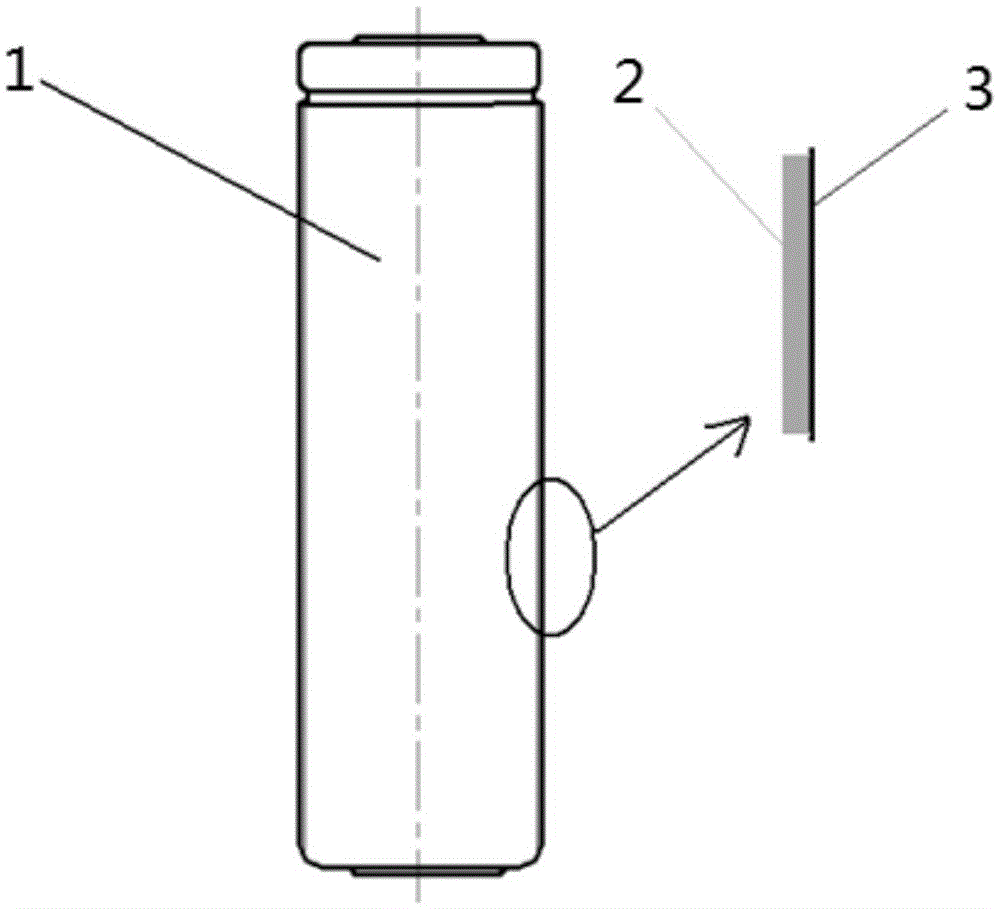

[0028] A lithium-ion battery with long shelf life, processed by:

[0029] Using polyvinylidene fluoride (PVDF) as a binder, nitrogen methylpyrrolidone (NMP) as a solvent, using a mixer to prepare the above materials into a glue solution, wherein the mass ratio of each material is as follows: binder: solvent = 6:94 , the glue solid content is 6%.

[0030] Apply the above glue on the inner wall of the 18650 battery steel case, spread evenly and dry. The thickness of the coating is less than or equal to 5 μm, thus completing the insulation treatment of the shell.

Embodiment 2

[0032] A lithium-ion battery with long shelf life, processed by:

[0033] Using polyvinylidene fluoride as a binder, nitrogen methylpyrrolidone (NMP) as a solvent, using a mixer to prepare the above materials into glue, wherein the mass ratio of each material is as follows: binder:solvent=6:94, the glue The liquid-solid content is 6%.

[0034] Apply the above glue on the inner wall of the 18650 battery steel case, spread evenly and dry. The thickness of the coating is 10 μm, thereby completing the insulation treatment of the shell.

Embodiment 3

[0036] A lithium-ion battery with long shelf life, processed by:

[0037] Adopt carboxymethyl cellulose (CMC) as binding agent, nitrogen methylpyrrolidone (NMP) is solvent, adopt agitator that above-mentioned material is formulated into glue solution, wherein each material mass ratio is as follows: binding agent: solvent=2 :98, the glue solid content is 2%.

[0038] Apply the above glue on the inner wall of the 18650 battery steel case, spread evenly and dry. The thickness of the coating is 10 μm, thereby completing the insulation treatment of the shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com