Making method of 3V chargeable button lithium battery lithium-aluminum alloy negative electrode

A lithium-aluminum alloy and a production method technology, which are applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low manufacturing speed of lithium-aluminum alloy negative electrodes, greatly restricting output, and improving, and achieve shortening time and cost. The effect of increasing the distance, increasing the generation speed, and expanding the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] (1) Weld the ML1220 negative electrode shell with a nickel mesh with a diameter of 3mm and a thickness of 0.2mm at the bottom of the inner side, then degrease, clean it, and dry it at 105°C for 4 hours;

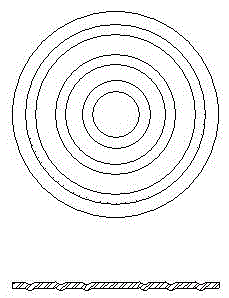

[0012] (2) On an aluminum plate with a purity of 99% and a thickness of 0.25 mm, two discs with a diameter of 9 mm are punched out, and four concentric ring grooves are punched out on one of the aluminum discs. The arc radius of the groove section is 0.3 mm, and the groove width is 0.5mm, 4 grooves are equidistantly distributed, then after degreasing and cleaning, blow dry at 105°C for 2 hours;

[0013] (3) In a drying room with a relative humidity of 0.9%, put the aluminum disc with a ring groove into the negative electrode case, with the ring groove facing up, press the aluminum disc with a plastic pressure head at 0.5 MPa on the pneumatic press, For 3 seconds, fix the aluminum disc inside the negative electrode shell, place a 10mg cube of battery-grade metal lithium...

Embodiment 2

[0017] (1) Weld the ML1220 negative electrode shell with a nickel mesh with a diameter of 3mm and a thickness of 0.2mm at the bottom of the inner side, then degrease, clean it, and dry it at 105°C for 4 hours;

[0018] (2) On an aluminum plate with a purity of 99% and a thickness of 0.25 mm, two discs with a diameter of 9 mm are punched out, and four concentric ring grooves are punched out on one of the aluminum discs. The arc radius of the groove section is 0.3 mm, and the groove width is 0.5mm, 4 grooves are equidistantly distributed, then after degreasing and cleaning, blow dry at 105°C for 2 hours;

[0019] (3) In a drying room with a relative humidity of 0.9%, put the aluminum disc with a ring groove into the negative electrode case, with the ring groove facing upward, press the aluminum disc with a plastic pressure head at 0.5MPa on a pneumatic press, For 3 seconds, fix the aluminum disc inside the negative electrode shell, put the 8mg cube of battery-grade metal lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com