Enamel powder, metal component having a surface portion provided with an enamel coating and method for producing such a metal component

A metal component, enamel powder technology, applied in the field of manufacturing the metal component, to achieve the effect of preventing further damage, and withstand thermal and mechanical loads reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

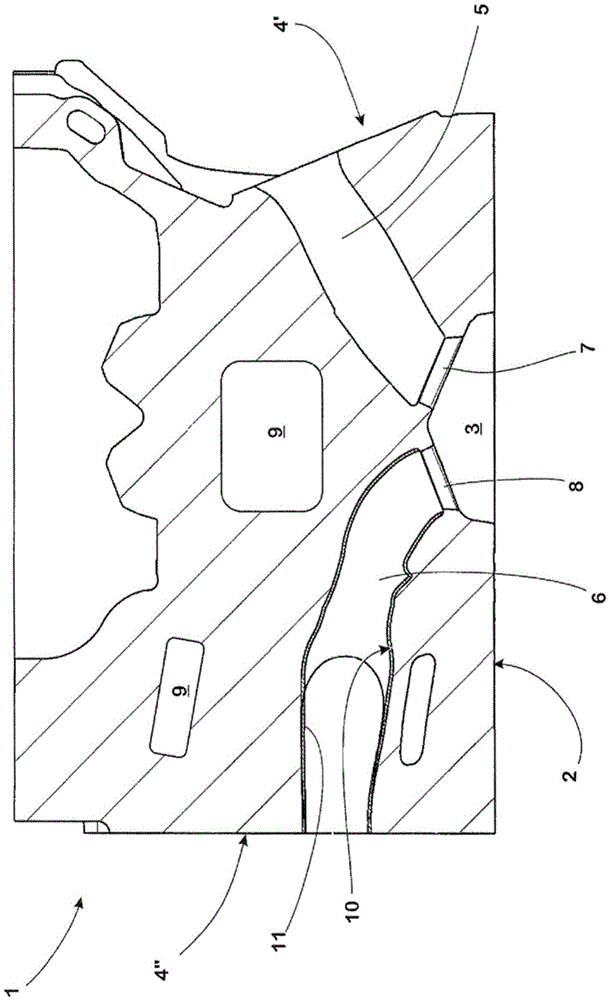

[0066] The cylinder head 1 of a gasoline or diesel engine cast from an aluminum material normally used for this purpose, such as an aluminum-silicon 11 alloy, has a flat contact surface 2, with which the cylinder head is inserted, if necessary, through it during use. A cylinder head gasket, not shown at , is located on the engine block of the respective internal combustion engine, also not shown. The internal combustion engine has sequentially arranged combustion chambers and a vertically moving piston, likewise not shown here.

[0067] In the contact surface 2, the number of cylinders of the internal combustion engine corresponds to the number of dome-shaped recesses 3 formed, which form the upper end cover of the combustion chamber of the internal combustion engine in the upward direction of the piston of the internal combustion engine.

[0068] In each of the recesses 3 is opened an intake opening 5 extending from the long side 4' of the cylinder head 1, through which the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com