Aqueous urea supply system for construction machine

A supply system and construction machinery technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve the problems of urea water freezing, inability to cool water pipe supply pipes, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

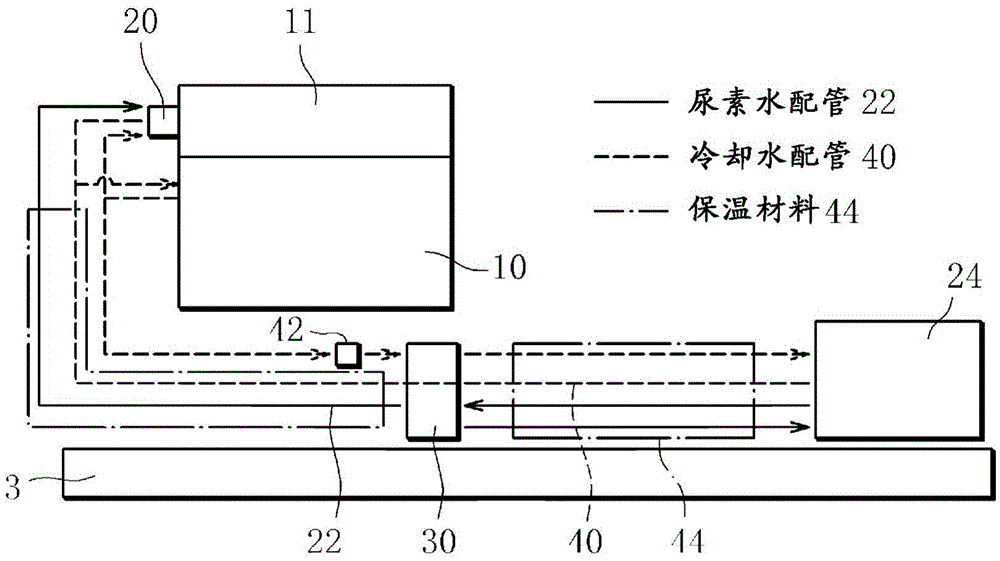

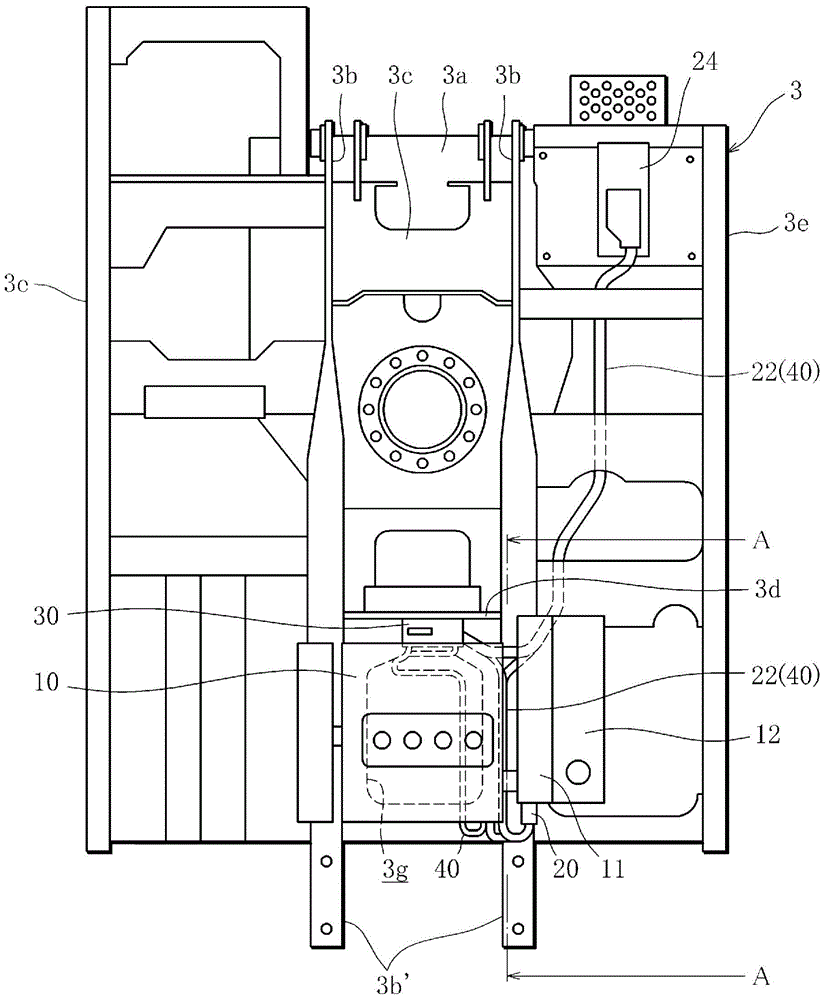

[0034] One embodiment of the urea water supply system for a construction machine according to the present invention will be described below based on the drawings.

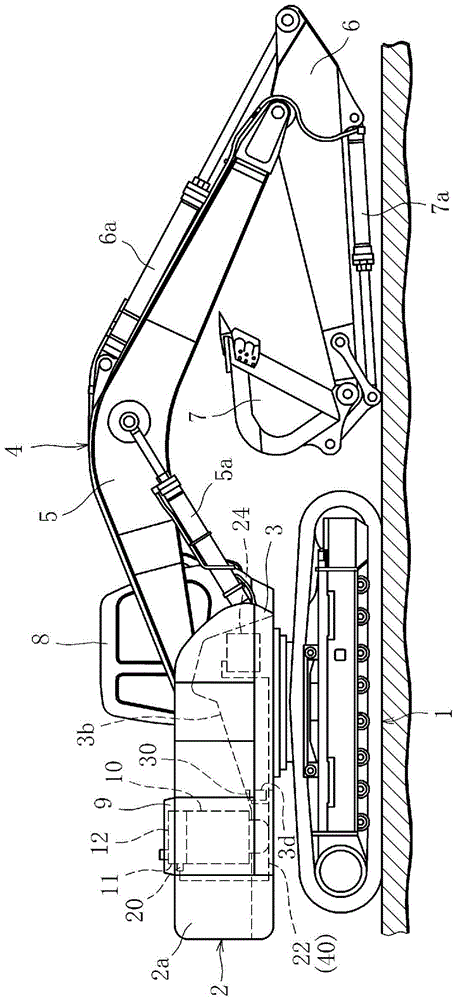

[0035] figure 1 A construction machine with the urea water supply system of the present invention is shown. In this embodiment, a crawler-type hydraulic excavator will be described as an example of a construction machine.

[0036] Such as figure 1 As shown, the hydraulic excavating mechanism has a traveling body 1, a rotating body 2 arranged on the traveling body 1 and mainly composed of a rotating frame 3, and an operation such as excavating sand and soil installed on the rotating body 2. device 4.

[0037] The working device 4 is configured to include a boom 5 rotatably attached to the swivel frame 3 in the up-down direction, an arm 6 rotatably attached to the front end of the boom 5 in the up-down direction, and an arm 6 rotatably attached in the up-down direction. A bucket 7 further mounted on the front end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com