Beak-style guide ditching device

A trench opener and guiding technology, which is applied to shovels, plows, agricultural machinery and implements, etc., can solve the problems of inability to meet the technical requirements of straw deep burial and returning to the field, deviation of trenching trajectory, and different depths of trenches. Large ditching space capacity, low working resistance and good ditching quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

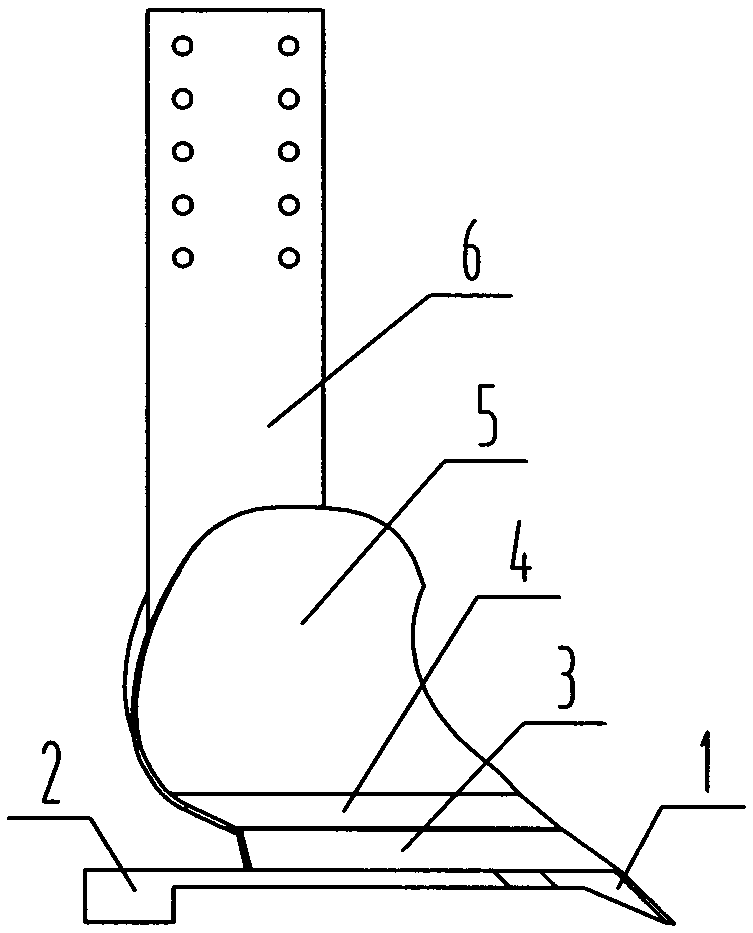

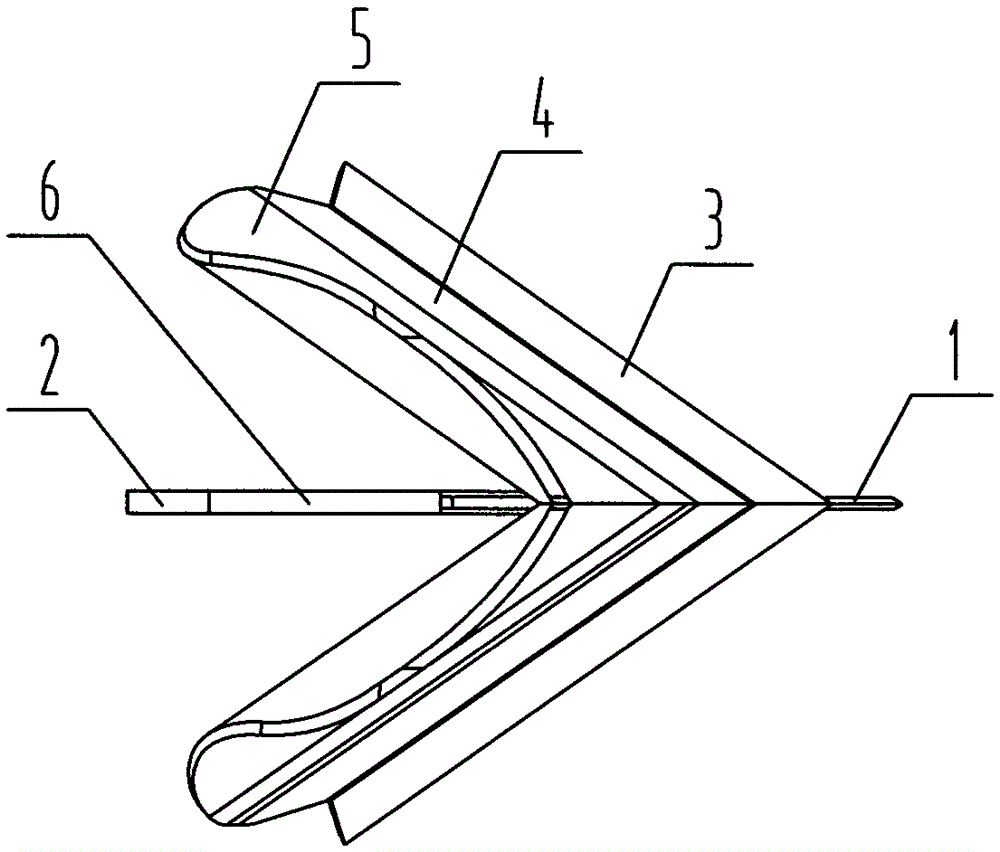

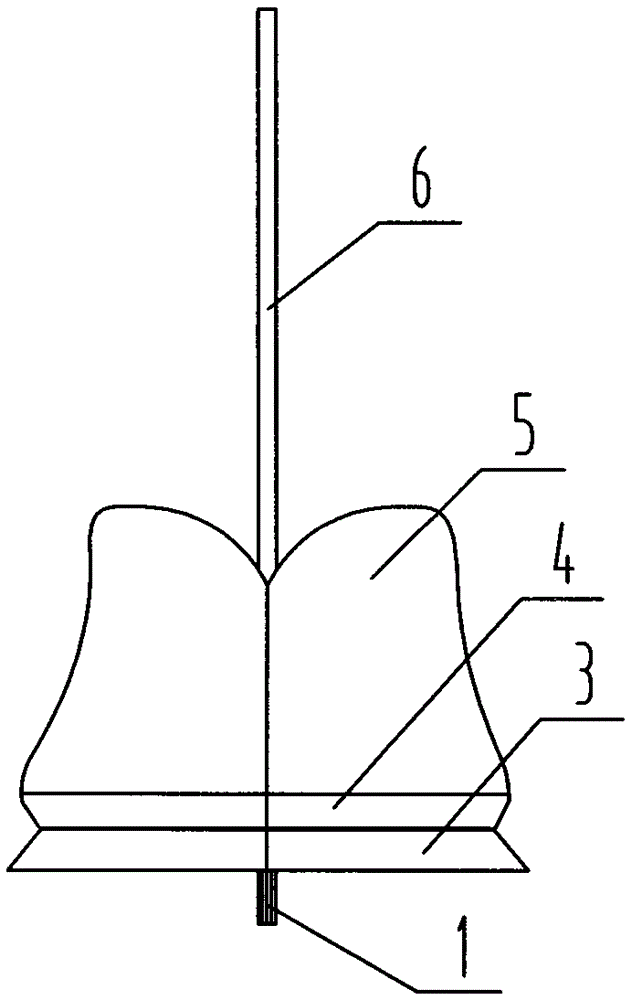

[0013] like figure 1 , figure 2 , image 3 As shown, a schematic diagram of the structure of the beak-type guide opener of the present invention is given, including a flat-shaped column handle 6, the lower end of the column handle 6 is horizontally provided with a guide straight knife 2, and the front end of the guide straight knife 2 is provided with a beak-type cutter head 1 , and the column handle 6 is in the same central vertical plane as the guide straight knife 2 and the beak-type cutter head 1, and is located on the upper part of the guide straight knife 2. The front ends of the two side soil sharers intersect in the center vertical plane to form a ditching curve, the lower tip of the ditching curve connects with the ditching edge line of the beak-type cutter head 1, and the two left and right side soil sharers from the The front end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com