Special preservative and preservation method for lotus mist fruit

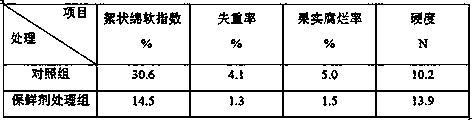

A fresh-keeping method and technology of a fresh-keeping agent, which are applied in the directions of fruit and vegetable fresh-keeping, application, food preservation, etc., can solve the problems of inability to effectively prevent the flocculent softness of lotus mist fruit, unclear mechanism and regulation mechanism, and influence on fruit quality and flavor, etc. Achieve the effect of delaying the decline of VC content and soluble solid content, easy to popularize and use, and retaining nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Select 12kg of lotus mist fruit with uniform size, consistent color and maturity, and no mechanical damage and infection by diseases and insect pests;

[0025] (2) Put the fruit in a 30 L vacuum desiccator, use a pure nitrogen cylinder to pass nitrogen gas (99.9%) into the desiccator for 20 minutes to discharge the oxygen in the desiccator, take 450 μL of NO gas, and inject it into the vacuum desiccator , so that the concentration of NO gas in the vacuum desiccator is 15 μL•L -1 , sealed for 60 minutes, then open the dryer to ventilate for 20 minutes;

[0026] (3) Put the NO gas-treated fruit into the container, and inject the prepared preservative solution into it. The concentration of the preservative is: naphthaleneacetic acid (NAA) 15 μmol L -1 , gibberellin (GA 3 ) 100 μmol L -1 , N-(2-chloro-4-pyridyl)-N’-phenylurea (CPPU) 50 μmol L -1 ;

[0027] (4) After immersing the fruit in the preservative solution for 8 minutes, put it in the air to ventilate and d...

Embodiment 2

[0033] (1) Select 12kg of lotus mist fruit with uniform size, consistent color and maturity, and no mechanical damage and infection by diseases and insect pests;

[0034] (2) Put the fruit in a 30 L vacuum desiccator, pass nitrogen gas (99.9%) into the desiccator with a pure nitrogen cylinder for 5 minutes to discharge the oxygen in the desiccator, and take it from the nitric oxide (NO) gas cylinder. Inject 3000 μL of NO gas with a purity of 99.9% into the vacuum desiccator so that the concentration of NO gas in the vacuum desiccator is 100 μL·L -1 , sealed for 30 minutes, then open the dryer to ventilate for 60 minutes;

[0035] (3) Put the NO gas-treated fruit into the container, and inject the prepared preservative solution into it. The concentration of the preservative is: naphthaleneacetic acid (NAA) 30 μmol L -1 , gibberellin (GA 3 ) 30 μmol L -1 , N-(2-chloro-4-pyridyl)-N’-phenylurea (CPPU) 150 μmol L -1 ;

[0036](4) The fruit must be immersed in the preservative ...

Embodiment 3

[0041] (1) Select 12kg of lotus mist fruit with uniform size, consistent color and maturity, and no mechanical damage and infection by diseases and insect pests;

[0042] (2) Put the fruit in a 30 L vacuum desiccator, use a pure nitrogen cylinder to blow nitrogen (99.9%) into the desiccator for 35 minutes to discharge the oxygen in the desiccator, and take it from the nitric oxide (NO) gas cylinder. Inject 60 μL of NO gas with a purity of 99.9% into the vacuum desiccator so that the concentration of NO gas in the vacuum desiccator is 2 μL·L -1 , sealed for 180 minutes, then open the dryer to ventilate for 10 minutes;

[0043] (3) Put the NO gas-treated fruit into the container, and inject the prepared preservative solution into it. The concentration of the preservative is: naphthaleneacetic acid (NAA) 0.5 μmol L -1 , gibberellin (GA 3 ) 300 μmol L -1 , N-(2-chloro-4-pyridyl)-N’-phenylurea (CPPU) 10 μmol L -1 ;

[0044] (4) The fruit must be immersed in the preservative so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com