High-dryness dewatering device for filter press and dewatering method thereof

A dewatering device and high dryness technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problem of inability to squeeze solid-liquid mixture materials to high dryness, and achieve higher extrusion pressure and higher solids content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

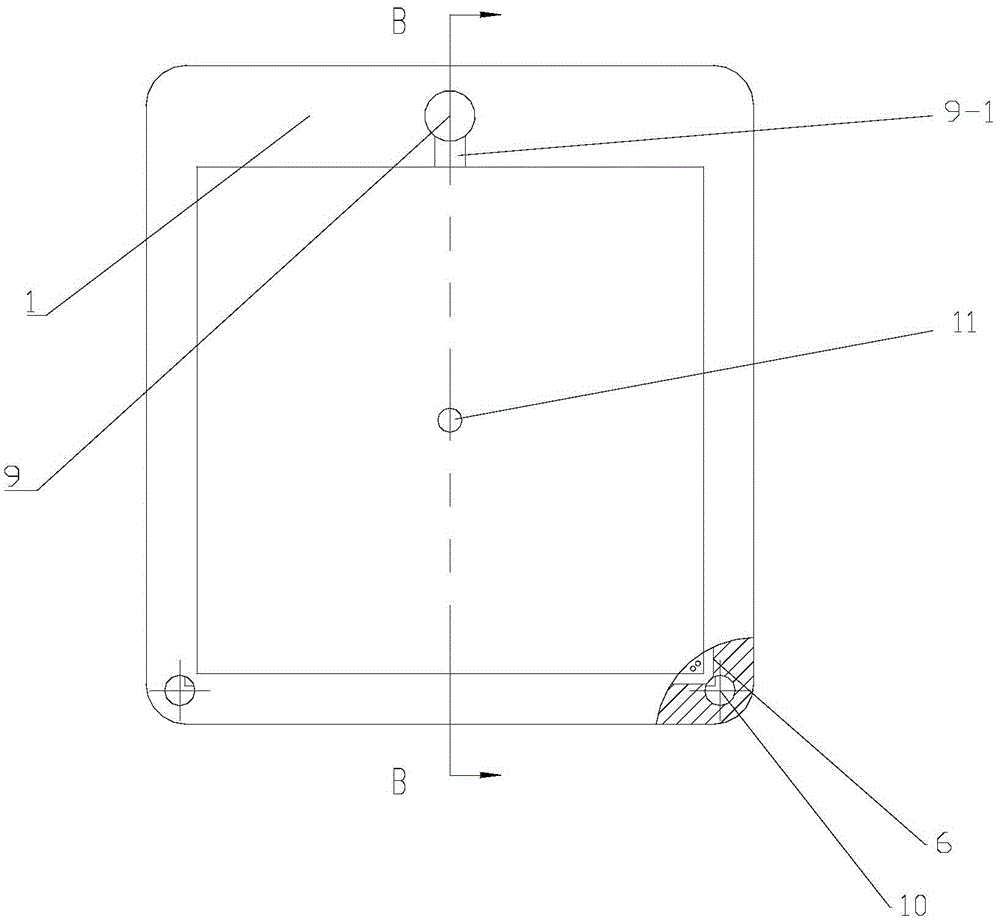

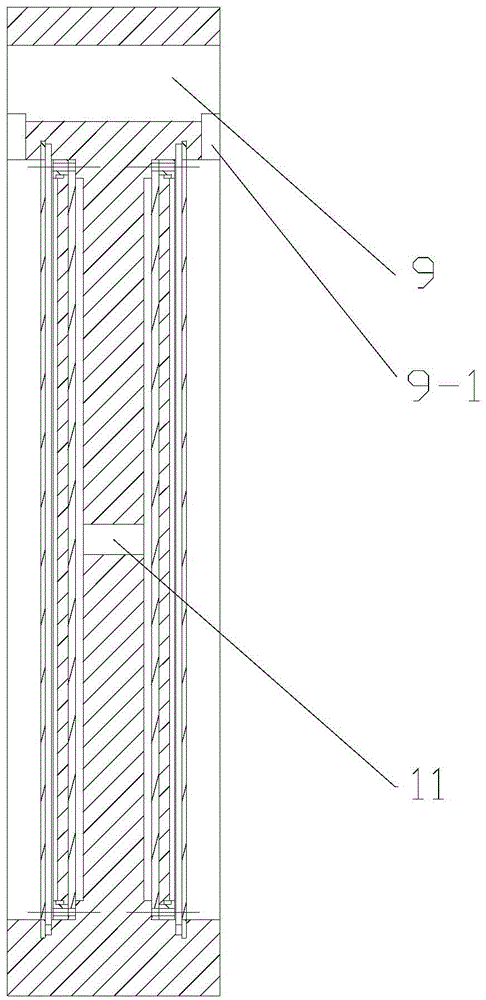

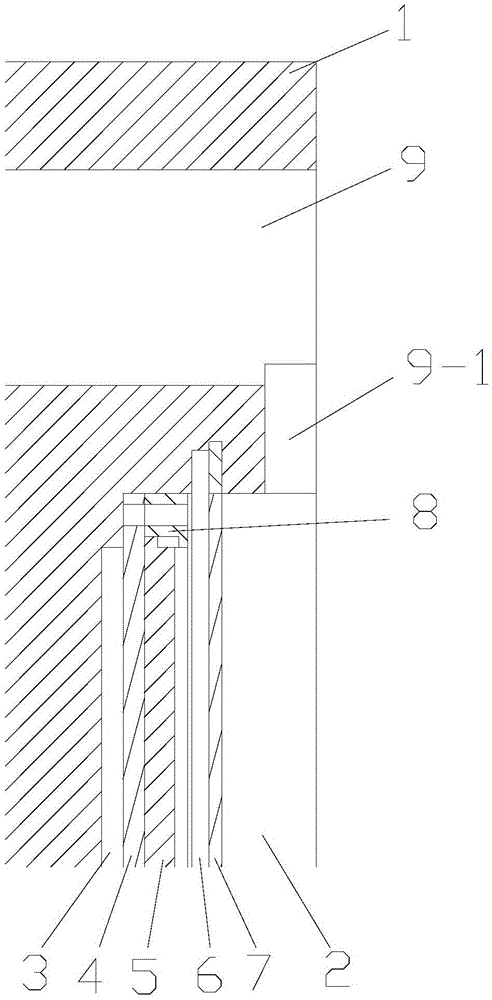

[0036] Such as Figures 1 to 7 shown. The present invention is a high-dryness dehydration device for a filter press, comprising a filter frame base 1, two surfaces of the filter frame base 1 are respectively symmetrically provided with two concave cavities 2 with the same structure, and each concave cavity 2 A hydraulic membrane 4, a filter plate 5, a jacket 8 and a filter cloth 7 are arranged sequentially from the inside to the outside;

[0037] The bottom of the cavity 2 is provided with hydraulic grooves 3, and each hydraulic groove 3 communicates with each other through the hydraulic oil injection port 11 opened in the middle of the filter frame base 1, and the hydraulic oil injection port 11 is opened inside the filter frame base 1. The channels connected to the external hydraulic oil injection equipment;

[0038] A feed inlet 9 is provided on the frame of the filter frame base 1, and the feed inlet 9 communicates with the cavity 2 (the outer position of the filter clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com