Method for manufacturing release steel plate for copper-clad plate

A manufacturing method and technology for copper clad laminates, which are applied to devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., can solve problems such as breakage, wrinkles, and easy sliding of the laid release film, and achieve the appearance of qualified , the effect of rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Step 1, wash the surface of the steel plate with deionized water to keep the surface of the steel plate in a wet state; then polish the steel plate with sandpaper; rinse the surface of the steel plate with deionized water after polishing, and polish and clean the surface of the steel plate with cotton cloth; rinse And the polishing and cleaning process is repeated several times until the surface of the steel plate is clean and free of dirt;

[0054] Step 2, use a hot air source to heat the surface-treated steel plate to keep the surface of the steel plate at a constant coating temperature of 90°C, and then apply the release material (hardened fatty acid) to the steel plate by rolling film-making method, so that A layer of release film is formed on the surface of the steel plate;

[0055] Covering and rolling film-making method is specifically:

[0056] 1) Soak the adsorption roller in the release material;

[0057] 2) After the adsorption roller reaches saturation, pl...

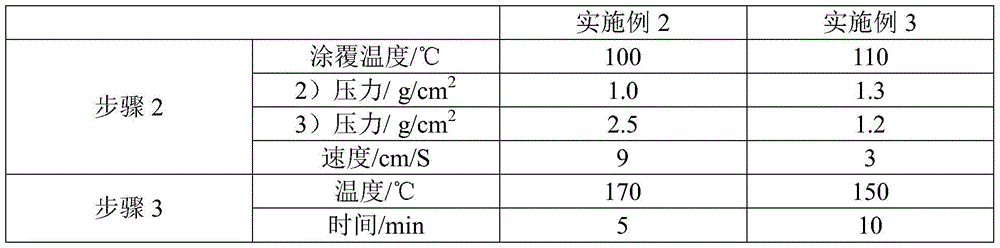

Embodiment 2~3

[0061] Referring to Example 1, the specific parameters are shown in Table 1.

[0062] The processing parameter of table 1 embodiment 2 and 3

[0063]

Embodiment 4

[0065] Step 1, wash the surface of the steel plate with deionized water to keep the surface of the steel plate in a wet state; then polish the steel plate with sandpaper; rinse the surface of the steel plate with deionized water after polishing, and polish and clean the surface of the steel plate with cotton cloth; rinse And the polishing and cleaning process is repeated several times until the surface of the steel plate is clean and free of dirt;

[0066] Step 2: Use a hot air source to heat the surface-treated steel plate to keep the surface of the steel plate at a constant coating temperature of 120°C, and then apply the release material (fluoroalkyl phosphate) on the On the steel plate, a layer of release film is formed on the surface of the steel plate;

[0067] The method of overlaying and flattening the film is as follows:

[0068] 1) Soak the cotton cloth with the release material;

[0069] 2) Lay the cotton cloth on the squeeze roller, and apply 1.5Kg / cm to the sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com