Semi-automatic electromagnetic riveting system for conical shell class structural part

A technology for electromagnetic riveting and structural parts, which is applied in the field of semi-automatic electromagnetic riveting systems for conical shell structural parts, can solve the problems of high labor intensity, poor consistency of riveting quality, and high rate of defective riveting, so as to reduce labor intensity and workload , Improve the quality of riveting, the effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

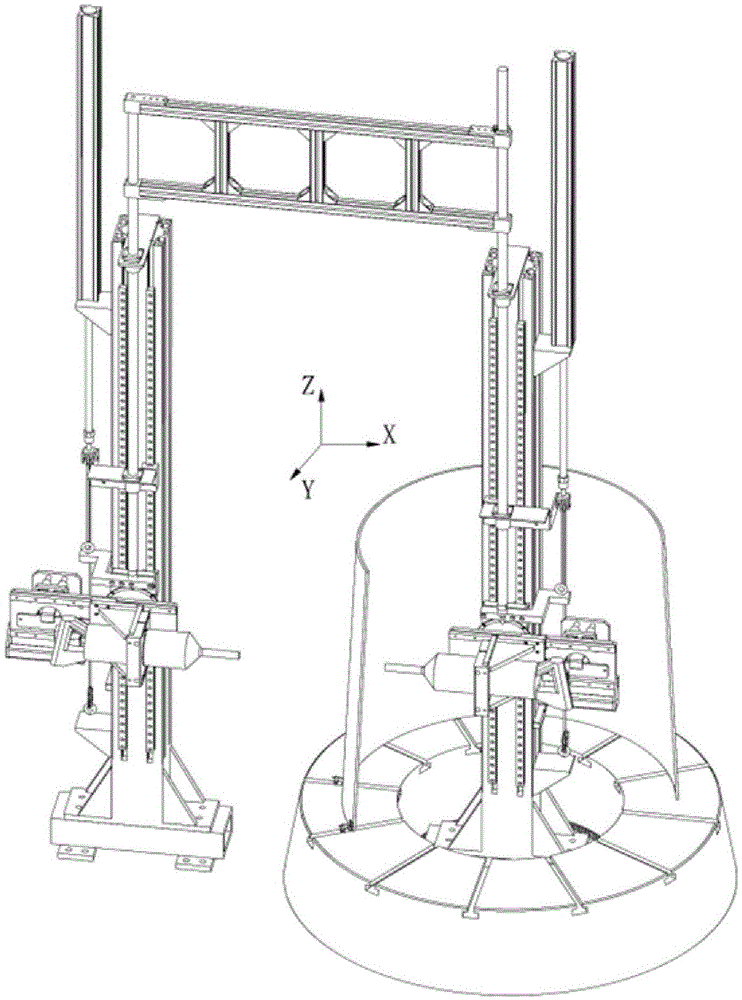

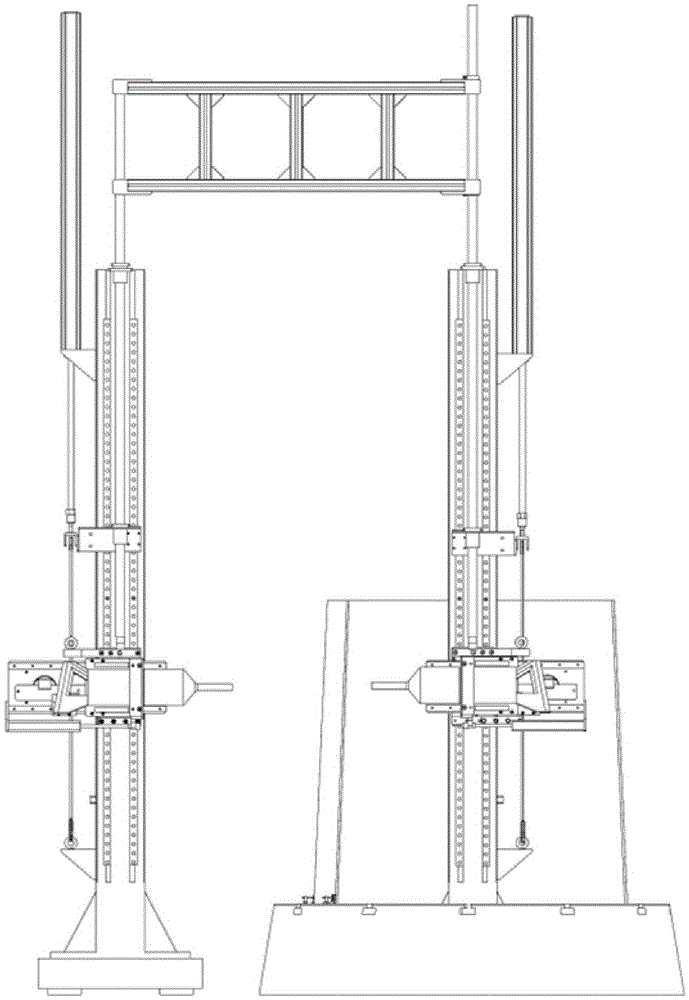

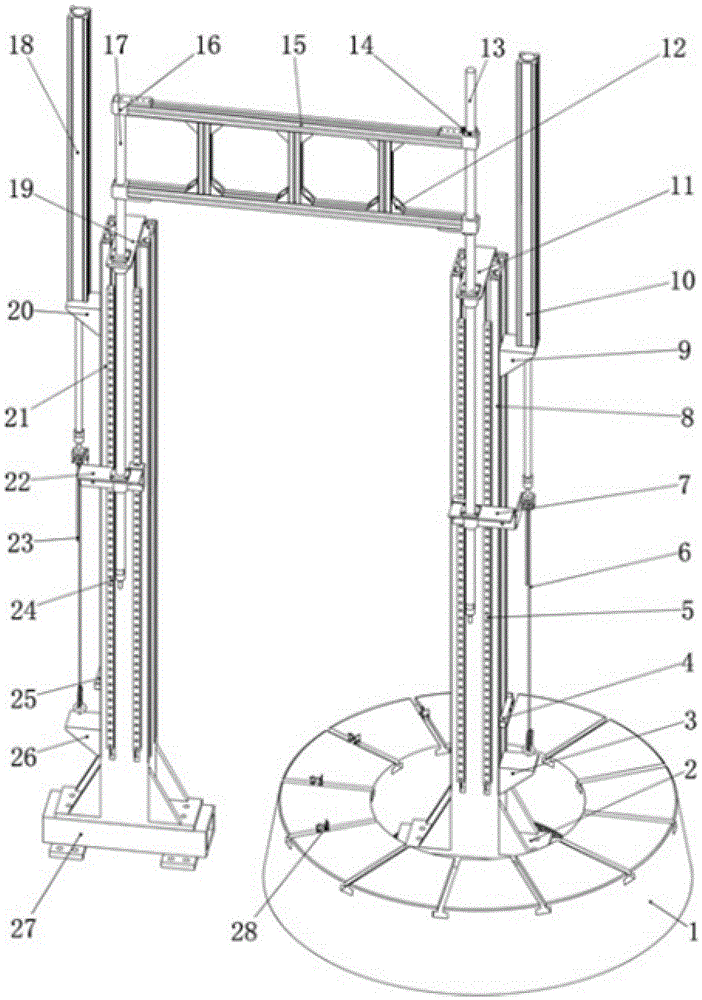

[0021] This embodiment is a semi-automatic electromagnetic riveting system for structural parts such as conical shells.

[0022] refer to Figure 1 to Figure 6, The semi-automatic electromagnetic riveting system for conical shell structural parts in this embodiment is composed of a frame linkage assembly, a riveting gun assembly, and a top handle assembly; the frame linkage assembly provides support for each component of the riveting system. The frame linkage assembly includes a turntable 1, a first bearing 2, a first support block 3, a first block 4, a first guide rail 5, a first steel wire rope 6, a first moving bearing plate 7, a first column 8, a second Support block 9, first balance cylinder 10, first fixed bearing plate 11, fixed block 12, first connecting rod 13, buckle 14, linkage frame 15, connecting buckle 16, second connecting rod 17, second balance cylinder 18 , the second fixed bearing plate 19, the third support block 20, the second column 21, the second movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com