Composite pipeline hot tapping plugging method

A technology of pressure-drilling and composite pipes, which is applied in the direction of pipes/pipe joints/fittings, pipes, branch pipelines, etc., can solve the problem of difficult sealing of the joint between the steel pipe and the liner pipe, and achieve a simple and easy sealing method. The effect of difficult sealing and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The method of the present invention will be described in more detail below through specific examples.

[0018] The method for plugging holes under pressure in composite pipe pipelines according to the present invention comprises the following steps:

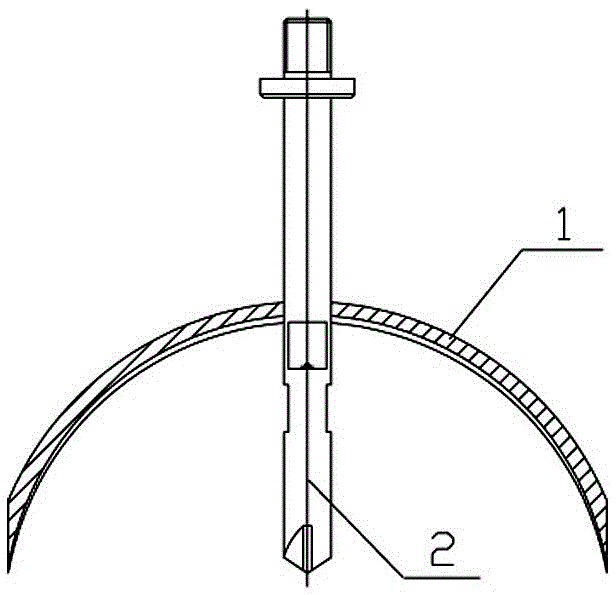

[0019] The first step is to weld the package tee at both ends of the main line, and use the hole opening equipment to open the hole on the steel-lined composite pipe according to the conventional method (the tooth width of the barrel knife can be 14mm), and cut the saddle-shaped material Sheet 1 (including outer steel pipe layer and inner liner pipe layer) is brought out by center drill 2, such as figure 1 shown;

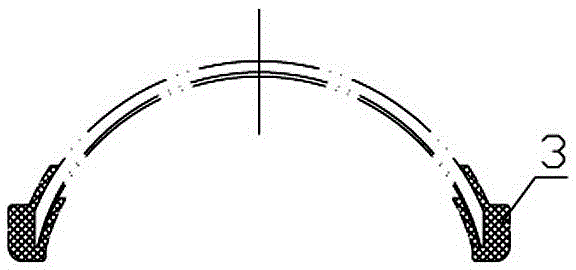

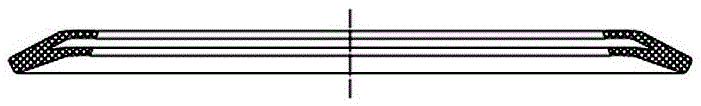

[0020] The second step is to accurately measure the outer diameter of the material piece 1 and the diameter of the opening on the steel-lined composite pipe, and use a mold to manufacture the rubber sealing ring 3 according to the size difference (the thickness of the sealing ring should be greater than the too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com