Cylindrical work piece bolt pressing apparatus

A technology for columnar workpieces and pressing devices, applied in positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of chuck wear, difficulty in disassembly, heavy weight, etc., and achieve low production cost, convenient production, and long service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

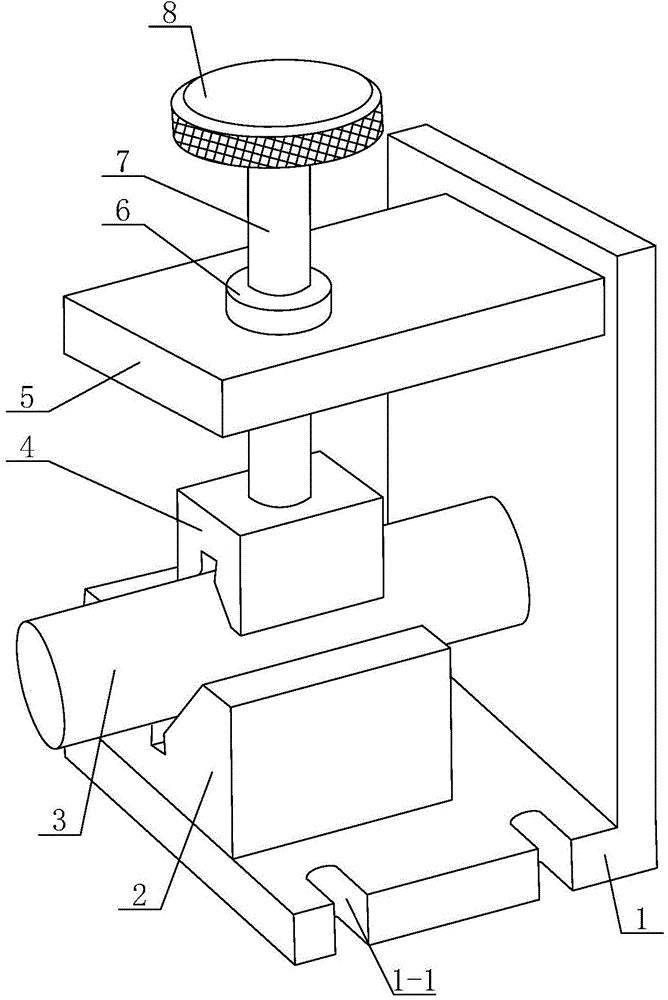

[0020] like figure 1 A cylindrical workpiece bolt pressing device shown includes an L-shaped mounting seat 1, the side wall of the L-shaped mounting seat 1 is provided with a plurality of fixing grooves 1-1 for fixing the L-shaped mounting seat 1, and It includes a threaded sleeve 6 and a screw 7 that cooperate with each other to form a thread pair; the upper side of the L-shaped mounting seat 1 is fixedly installed with a V-shaped groove pad 2 for supporting the columnar workpiece 3, and the side wall of the L-shaped mounting seat 1 is fixedly installed There is a transverse support plate 5, the threaded sleeve 6 is fixedly arranged on the transverse support plate 5, the screw rod 7 is arranged inside the threaded sleeve 6, and the lower end of the screw rod 7 is rotated to be used for compressing the columnar workpiece. 3 V-shaped groove pressure head 4, and the upper end of the screw rod 7 is fixedly provided with a rotating handle 8.

[0021] In this embodiment, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com