Concrete crack autolysis self-repairing system and preparation method thereof

A self-healing, concrete technology, applied in the field of concrete engineering, can solve the problems of residue, matrix strength and durability, etc., and achieve the effect of low cost, simple preparation method and good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

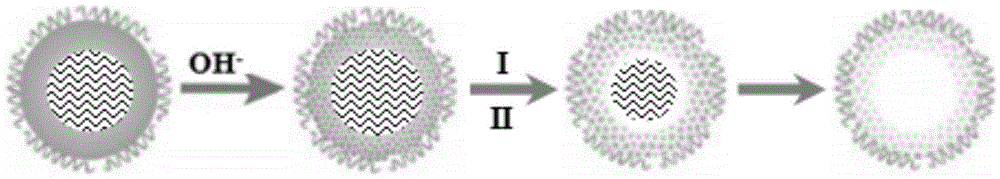

[0058] Such as figure 1 As shown, porous or hollow SiO 2 The microspheres are loaded with repair agent by impregnation method, and then the surface is also loaded with a polymer protective film by impregnation; such a single microsphere is slowly eroded in the alkaline environment of cement-based materials. First, the protective film is slowly eroded and decomposed in the alkali, making the inorganic When the microspheres are exposed to an alkaline environment, the pores on the surface of the microspheres expand, opening channels for the repair agent to flow out; the repair process mainly plays a repair role through the following two ways: (1) when the cement-based material is destroyed and the external water environment enters , due to the concentration difference between the inside and outside of the microsphere, the repair agent is released through the pores on the surface and Ca 2+ Generate C-S-H to repair. Ca 2+ The repair agent is consumed to generate gel precipitatio...

Embodiment 2

[0076] Accurately weigh 70g sodium silicate nonahydrate and add 230ml deionized water to make 10% sodium silicate solution (converted to SiO 2 Concentration is 54.6mg / ml), reserved for adsorption.

[0077] A part of SiO was treated by double salt pore expansion method. 2 The microspheres were subjected to pore expansion treatment, and 60mg of pore expansion SiO was weighed 2 and 60mg of unexpanded SiO 2 Immerse the microspheres in 60g (density 1.09g / ml, volume 55.04ml) sodium silicate solution, place it for 1d after ultrasonic dispersion, after 1d, centrifuge the solution in a centrifuge at 9000rad for 20min, absorb the supernatant according to the steps of preparing the working solution Prepare the solution, measure its absorbance, and query the corresponding concentration value according to the fitting curve, and then calculate the hole expansion and the hole expansion SiO2 from the difference between the initial concentration and the final concentration. 2 The adsorption...

Embodiment 3

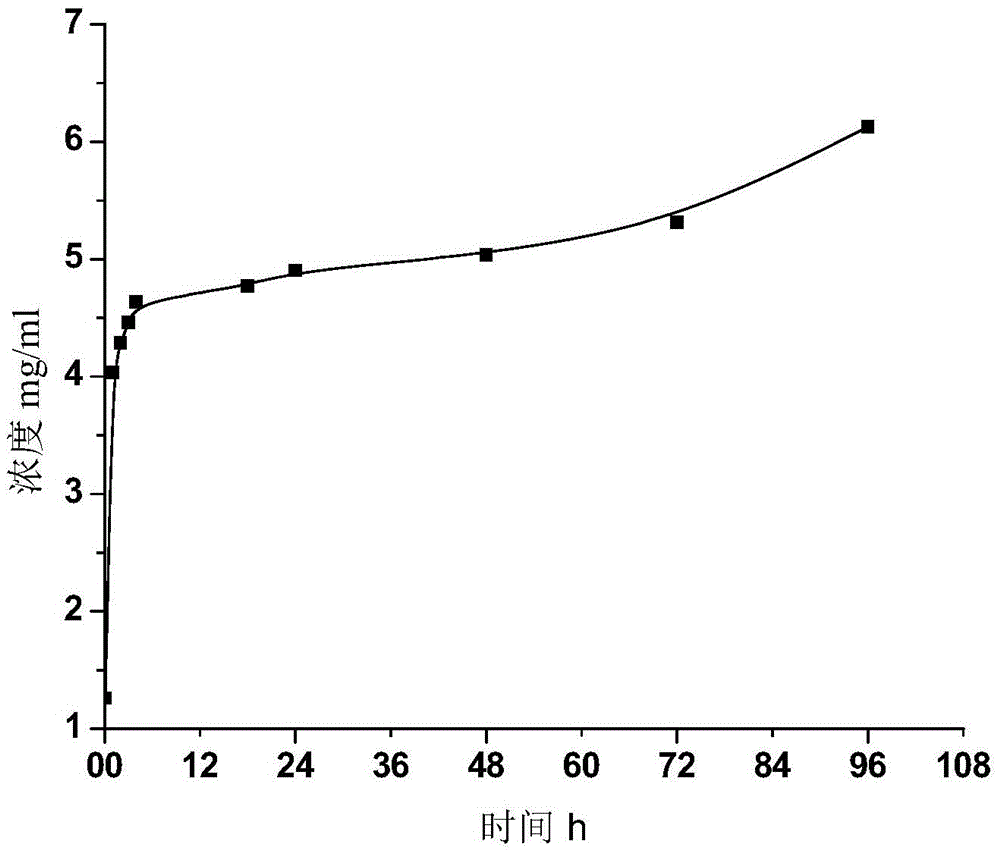

[0085] In order to study expanded and unexpanded SiO 2 The release situation of microsphere carrier to sodium silicate, the present invention will 80mg hole-expanding SiO 2 Microspheres and Unexpanded SiO 2 Dip the microspheres in 80g of 10% sodium silicate solution and ultrasonically disperse them and let them stand for 1d. After the microspheres are fully adsorbed with sodium silicate, centrifuge them in a centrifuge at a speed of 9000r / min to obtain SiO adsorbed with sodium silicate. 2 Microspheres. Take 19mg unexpanded SiO 2 Microspheres and 17 mg pore-expanding SiO 2 The microspheres were respectively placed in 100ml of distilled water, and 10ml of the solution was taken out at regular intervals, and the samples were prepared for the spectrophotometric test according to the sample preparation method of the spectrophotometric test. Compare the obtained absorbance with the standard curve, find out the concentration value and draw a curve.

[0086] Drawing reamed and un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com