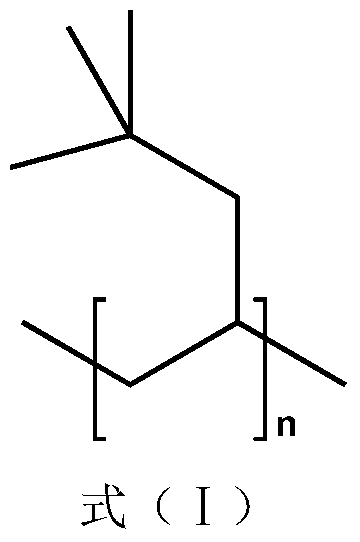

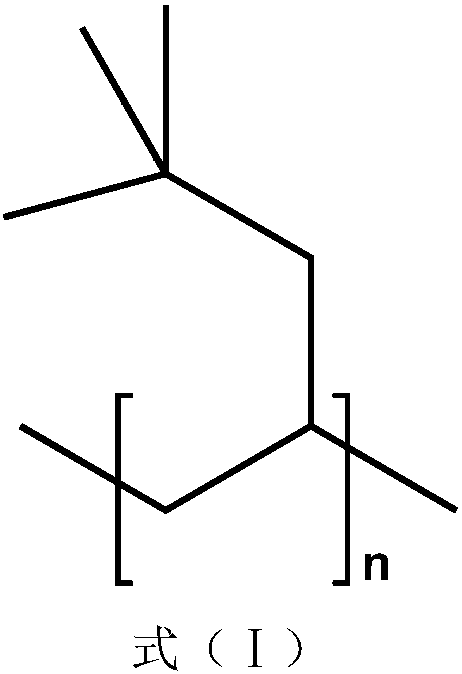

A kind of olefin polymer and its production method

A technology for olefin polymers and manufacturing methods, which is applied in the field of olefin polymerization, and can solve the problems of high polymer ash content, low monomer conversion rate, low polymerization activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The dry reactor was evacuated and flushed with nitrogen three times repeatedly. At room temperature, start stirring, add appropriate amount of toluene, 1.0 ml 4,4-dimethyl-1-pentene, 6.0 ml MAO toluene solution, 1.0 ml containing 20 micromole racemic ethylene-bridged bis-indenyl dichloride Zirconium solution in toluene, start timing. After 48 hours, stop stirring, carefully pour the reaction solution into a beaker, add acidified ethanol, stir for more than 6 hours, filter to obtain the polymer, and vacuum-dry the filter cake at 60°C for 24 hours, weigh to obtain 0.45 g of the polymer, monomer The weight conversion was 66%. The melting point of the polymer was 207°C as measured by DSC.

Embodiment 2

[0032] The dry reactor was evacuated and flushed with nitrogen three times repeatedly. At 50°C, start stirring, and add an appropriate amount of toluene, 1.0 ml of 4,4-dimethyl-1-pentene, 6.0 ml of MAO toluene solution, and 1.0 ml of 20 micromole racemic dimethylsilyl-diindenyl Zirconium dichloride in toluene solution, start timing. After 48 hours, stop stirring, carefully pour the reaction solution into a beaker, add acidified ethanol, stir for more than 6 hours, filter to obtain the polymer, and vacuum-dry the filter cake at 60°C for 24 hours, weigh to obtain 0.49 g of the polymer, monomer The weight conversion rate was 72%. The melting point of the polymer was 211°C as measured by DSC.

Embodiment 3

[0034] The dry reactor was evacuated and flushed with nitrogen three times repeatedly. At room temperature, start stirring, add appropriate amount of toluene, 1.0 ml 4,4-dimethyl-1-pentene, 6.0 ml MAO toluene solution, 1.0 ml containing 20 micromole racemic dimethylsilyl bridge bis(2- Methyl-4-phenyl-indenyl) toluene solution of zirconium dichloride, start timing. After 48 hours, stop stirring, carefully pour the reaction solution into a beaker, add acidified ethanol, stir for more than 6 hours, filter to obtain the polymer, and vacuum-dry the filter cake at 60°C for 24 hours, weigh to obtain 0.52 g of the polymer, monomer The weight conversion rate was 76%. According to the DSC test, the melting point of the polymer is 223°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com