Residue oil hydrotreatment catalyst grading method and residue oil hydrotreatment method

A technology for residual oil hydrogenation and catalyst, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problem that the removal rate of carbon residue is not obvious, and achieve the reduction of catalyst carbon deposition, uniform distribution, The effect of strong carbon deposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example is used to illustrate the catalyst grading method for residual oil hydrotreating and the method for residual oil hydrotreating provided by the present invention.

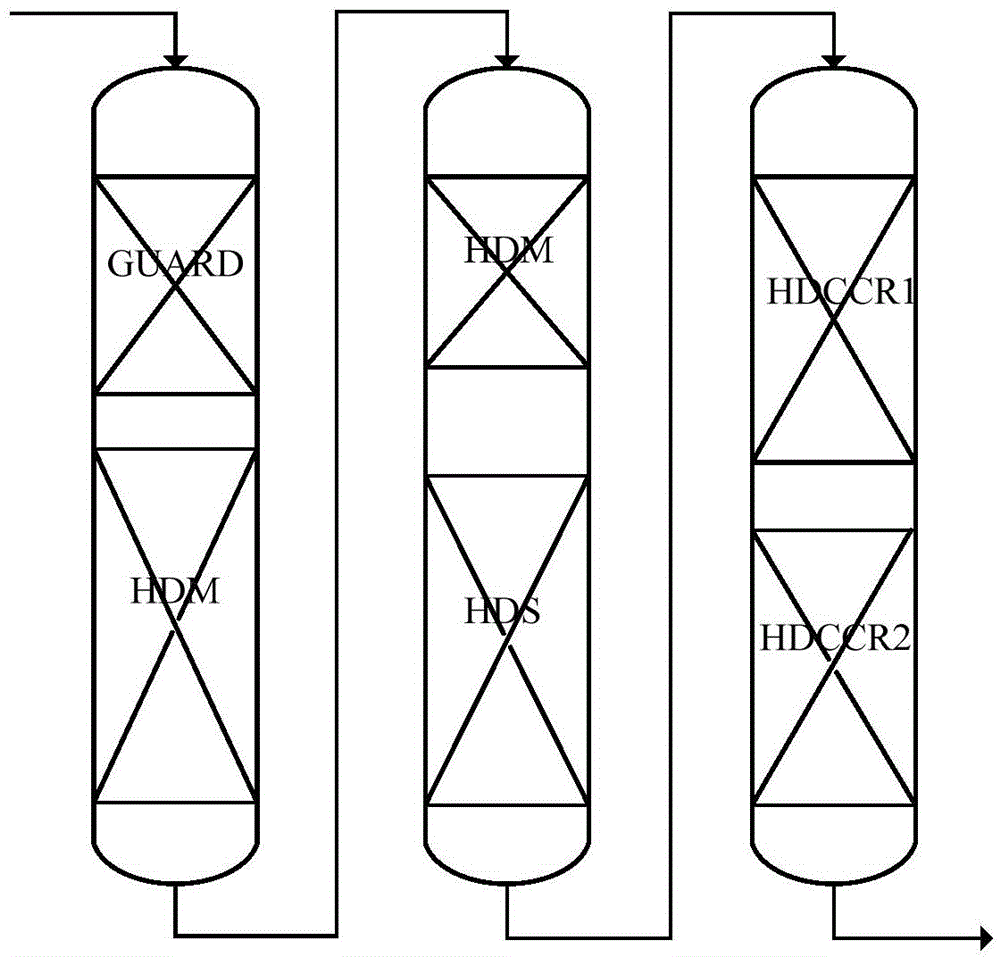

[0051] The reactor is filled with G1, M1, S1 and CCR1 sequentially from front to back, and the filling volume ratio is 5:35:30:30. The residual oil and hydrogen were mixed and then injected into the reactor for hydrotreating. The conditions of hydrotreating are shown in Table 3, and the removal rate of impurities is shown in Table 4.

Embodiment 2

[0055] This example is used to illustrate the catalyst grading method for residual oil hydrotreating and the method for residual oil hydrotreating provided by the present invention.

[0056] According to the method of Example 1, the residual oil hydrotreating is carried out, the difference is that the reactor is filled with G1, M1, S2, CCR2 and CCR1 in sequence from front to back, and the filling volume ratio is 5:35:30:15:15, Its impurity removal rate is shown in Table 4.

Embodiment 3

[0060] This example is used to illustrate the catalyst grading method for residual oil hydrotreating and the method for residual oil hydrotreating provided by the present invention.

[0061] In this example, the raw material oil and test conditions are the same as in Example 1. The reactor is filled with G1, M1, S2 and CCR1 in sequence from front to back, and the filling volume ratio is 5:35:30:30. The removal rate of impurities is shown in the table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com