A water storage flush toilet

A toilet and flush-down technology, which is applied in the field of water-storage flush-down toilets, can solve problems such as low washing flow and pressure, increase equipment cost, and failure to achieve, and achieve good space saving, convenient production and maintenance, and high precision. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

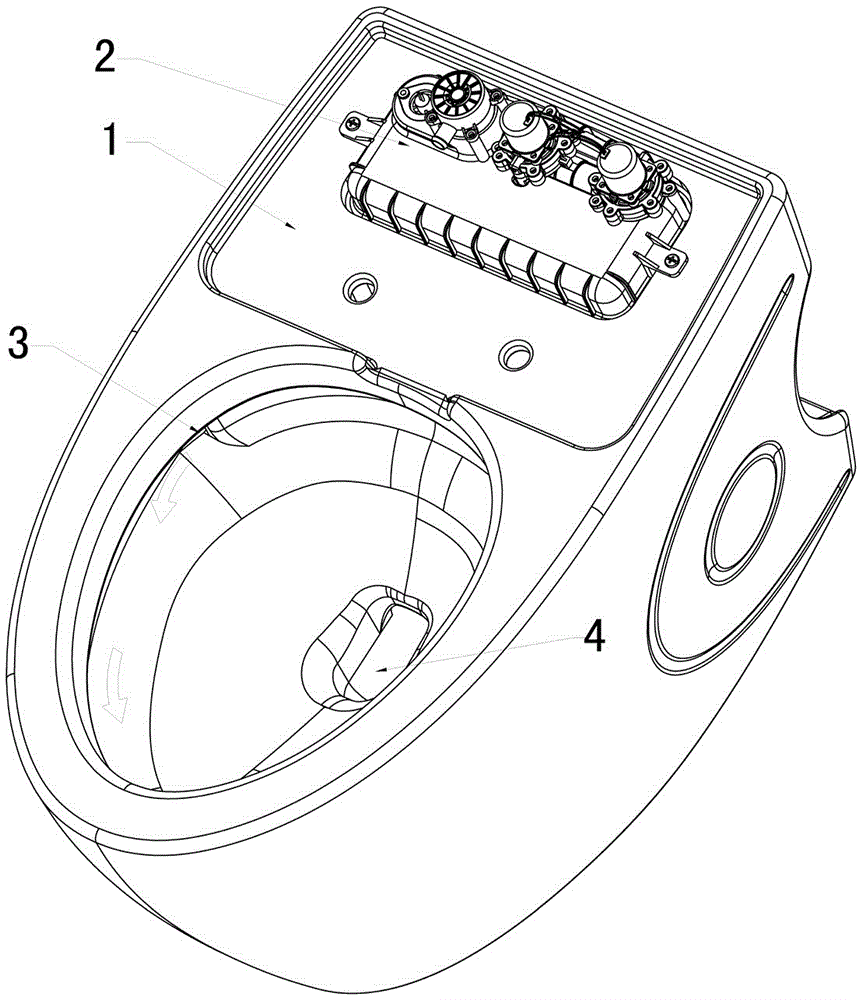

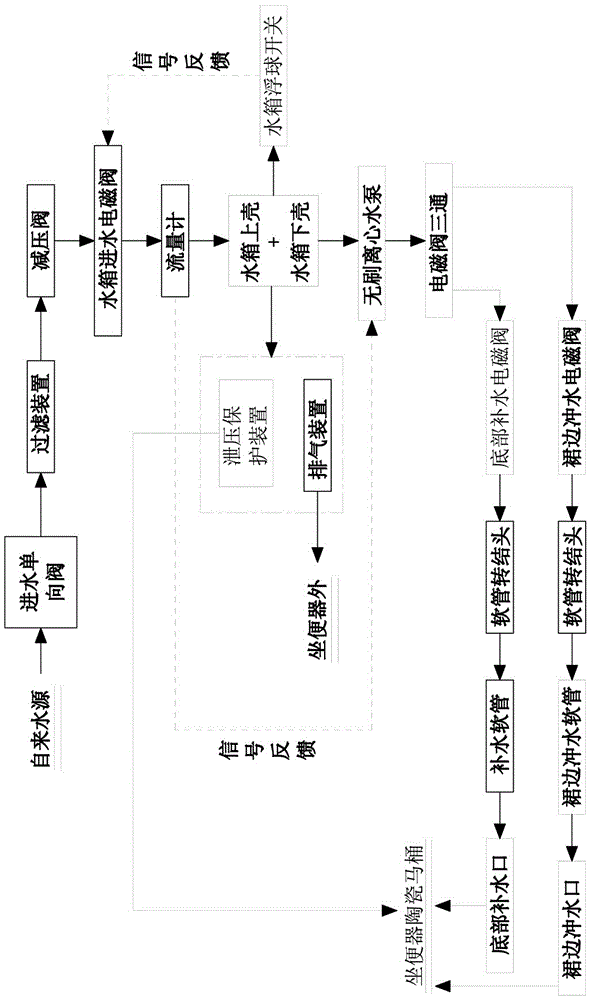

[0028] figure 1 It is a schematic diagram of a water storage flush toilet according to the present invention. The toilet disclosed by the present invention comprises a toilet main body 1 and a water storage direct flush flushing device 2 . The toilet body 1 is provided with a skirt flush port 3 and a bottom replenishment port 4, wherein the skirt flush port 3 is connected to the skirt flush solenoid valve 19 through the skirt flush hose 22, and the bottom replenishment port 4 is connected to the skirt flush solenoid valve 19 through the skirt flush hose 22. The water supply hose 23 is connected with the bottom water supply solenoid valve 21 . When the user instructs to flush, the tap water is successively discharged through the skirt flush port 3 and the bottom water replenishment port 4 .

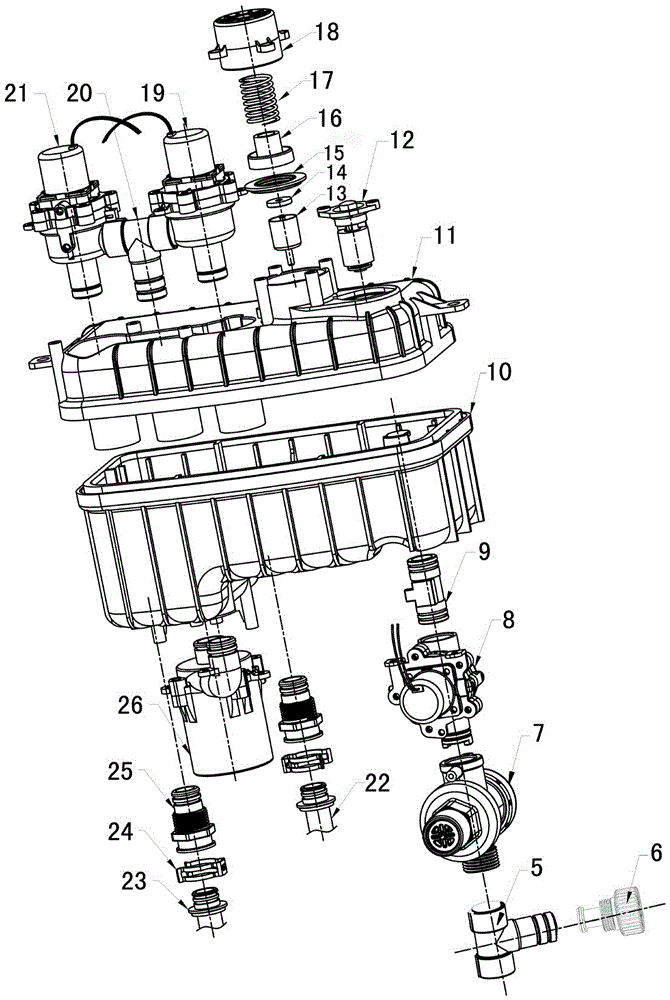

[0029] As an important improvement point of the present invention, the water storage direct flushing flushing device 2 of the present invention will be described in detail below.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com