Mounting and fixing device for pre-cast shear wall and use method of mounting and fixing device

A technology of prefabricated shear force and fixing device, applied in the direction of walls, building components, buildings, etc., can solve the problems that the concrete strength cannot meet the force requirements, reduce the working efficiency of tower cranes, and prematurely install top explosion screws, so as to shorten the construction period. , The effect of reducing wet work workload and fast installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred modes of the present invention will be described in further detail below in conjunction with the examples.

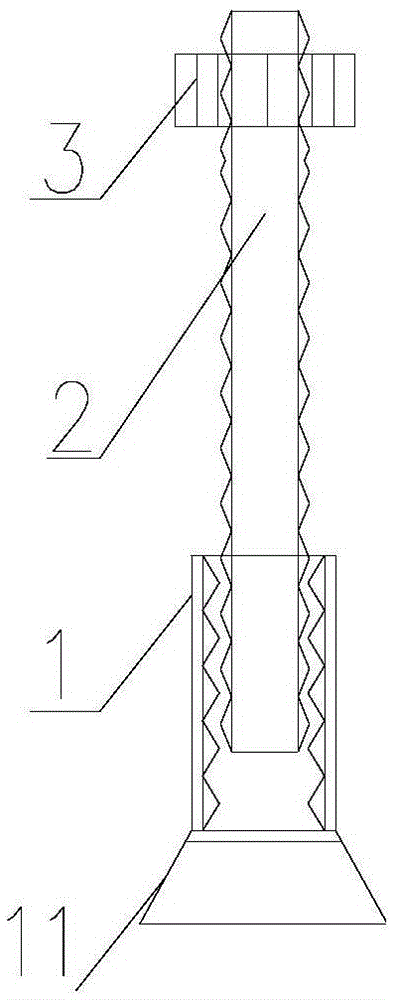

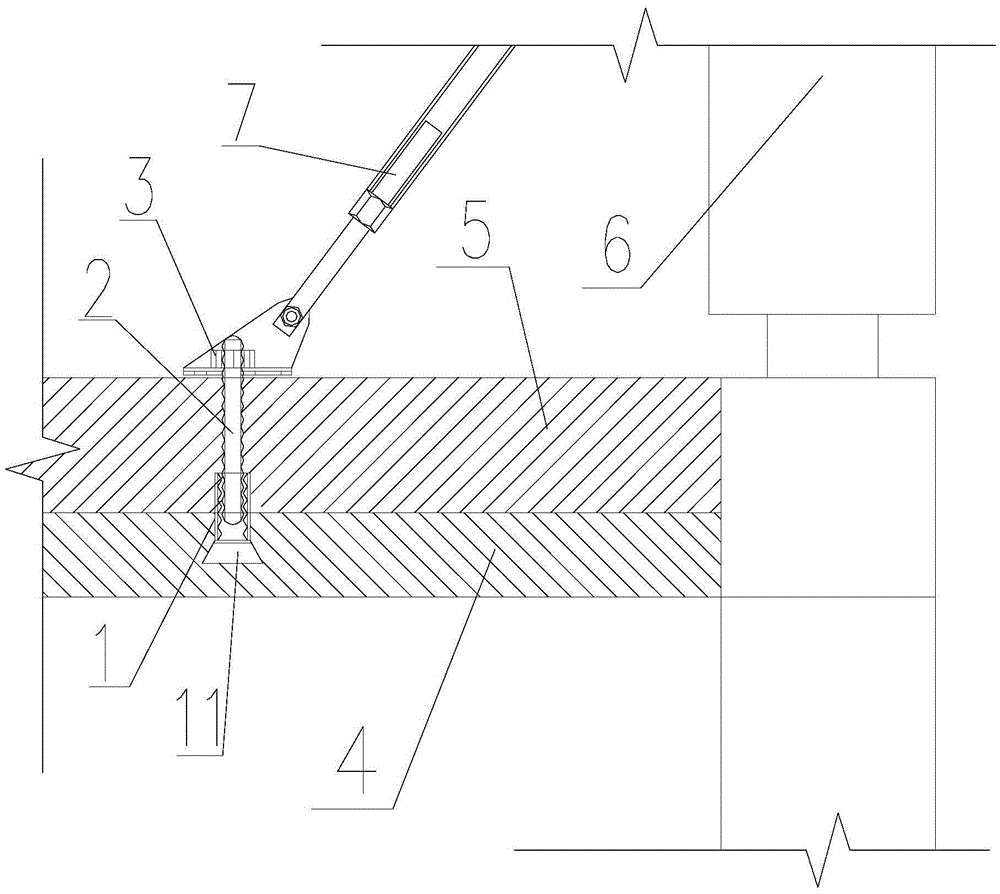

[0017] Such as figure 1 As shown, a prefabricated shear wall installation and fixing device includes an anchor dowel 1, a fine-tuning bolt rod 2 and a fastening nut 3. A cavity is provided at one end of the anchor dowel 1, and a cavity is provided on the inner wall of the cavity. There is an internal thread matched with the thread on the fine-tuning bolt rod 2, and the two ends of the fine-tuning bolt rod 2 are respectively connected with the anchor dowel 1 and the fastening nut 3 by threads.

[0018] In order to further optimize the technical solution, the cavity of the anchoring dowel 1 has one and only one open end, and the end of the anchoring dowel 1 away from the opening end is provided with a concrete contact area for enlarging the anchoring dowel and the laminated floor 4 The expansion part 11. The section of the enlarged portion 11 is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com