Constant-air-volume motor drive control method for fan

A technology of motor drive control and constant air volume, applied in motor control, engine control, pump control, etc., can solve the problems of increased hardware cost, high dependence of position sensor, failure of position sensor, etc., to reduce equipment cost and wide application range , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

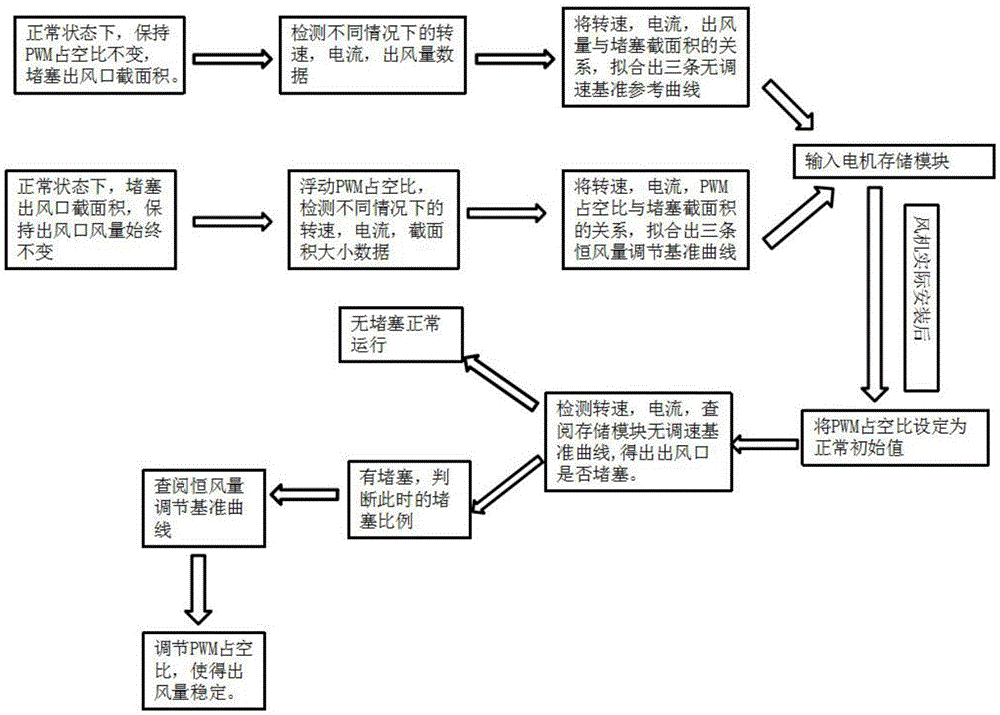

[0024] Embodiment 1: Mainly by monitoring the motor speed N x and other parameters to realize the driving control of the fan constant air volume motor, the control method includes the following steps:

[0025] (1) Determine the initial value Duty of the PWM duty cycle of the motor winding under the normal state of the air duct 0 , Air volume CFM at the air duct opening 0 , the current motor speed N 0 , where PWM is PulseWidthModulation, the abbreviation of Pulse Width Modulation.

[0026] (2) Keep the initial value Duty of the PWM duty cycle of the motor winding 0 The air duct opening is blocked in proportion; the initial cross-sectional area of the air duct opening is S 0 , the effective cross-sectional area of ventilation after blockage is S x , get different S x The air volume at the air outlet under the value CFM x , motor speed N x ; Take the blockage area ratio S of the air duct opening x / S 0 is the abscissa, and the air volume at the air outlet is CFM x ...

Embodiment 2

[0030] Embodiment 2: Mainly by monitoring the motor current I x and other parameters to realize the driving control of the fan constant air volume motor, the control method includes the following steps:

[0031] (1) Determine the initial value Duty of the PWM duty cycle of the motor winding under the normal state of the air duct 0 , Air volume CFM at the air duct opening 0 , current motor current I 0 , where PWM is PulseWidthModulation, the abbreviation of Pulse Width Modulation.

[0032] (2) Keep the initial value Duty of the PWM duty cycle of the motor winding 0 The air duct opening is blocked in proportion; the initial cross-sectional area of the air duct opening is S 0 , the effective cross-sectional area of ventilation after blockage is S x , get different S x The air volume at the air outlet under the value CFM x , motor current I x; Take the blockage area ratio S of the air duct opening x / S 0 is the abscissa, and the air volume at the air outlet is CFM x...

Embodiment 3

[0037] Embodiment 3: Mainly by simultaneously monitoring the motor current I x and motor speed N x and other parameters to realize the driving control of the fan constant air volume motor, the control method includes the following steps:

[0038] (1) Determine the initial value Duty of the PWM duty cycle of the motor winding under the normal state of the air duct 0 , motor speed N 0 , motor current I 0 , Air volume CFM at the air duct opening 0 ; Wherein, PWM is PulseWidthModulation, the abbreviation of pulse width modulation.

[0039] (2) Keep the initial value Duty of the PWM duty cycle of the motor winding 0 The air duct opening is blocked in proportion; the initial cross-sectional area of the air duct opening is S 0 , the effective cross-sectional area of ventilation after blockage is S x , get different S x The motor speed under the value N x , motor current I x , air volume at air outlet CFM x ; Take the blockage area ratio S of the air duct opening x / S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com