Method for rebuilding double-section rubber membrane sealed dry gas holders from polygonal thin oil sealed dry gas holders

A technology of gas cabinets and rubber membranes, applied in the field of gas cabinets, can solve the problems of multi-project time and cost, waste of construction materials, poor gas storage effect, etc., and achieve the effect of saving engineering time, saving engineering costs and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

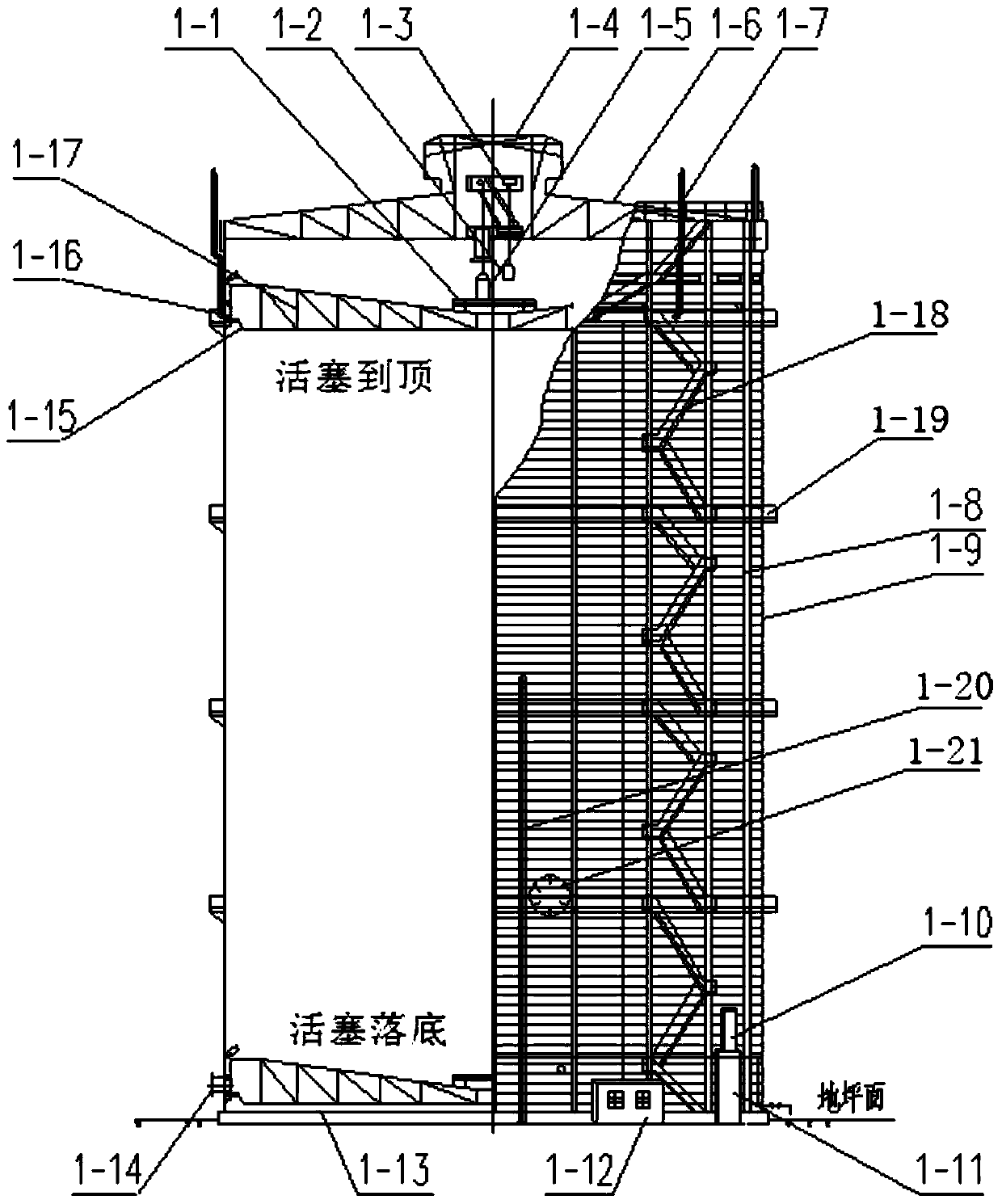

[0053] like figure 1 As shown, the conventional polygonal thin oil-sealed dry-type gas tank includes an internal cage landing platform 1-1, a manual rescue bag 1-2, an internal cage platform 1-3, a ventilation floor 1-4, and an internal cage 1 -5, top plate 1-6, emergency relief pipe 1-7, column 1-8, side plate 1-9, external elevator shaft 1-10, external elevator machine room 1-11, oil pump station 1-12, bottom plate 1-13 , gas inlet and outlet pipe 1-14, piston ring beam 1-15, sealing device 1-16, piston 1-17, inclined ladder 1-18, corridor 1-19, replacement and release pipe 1-20, cabinet capacity indicator 1 -twenty one.

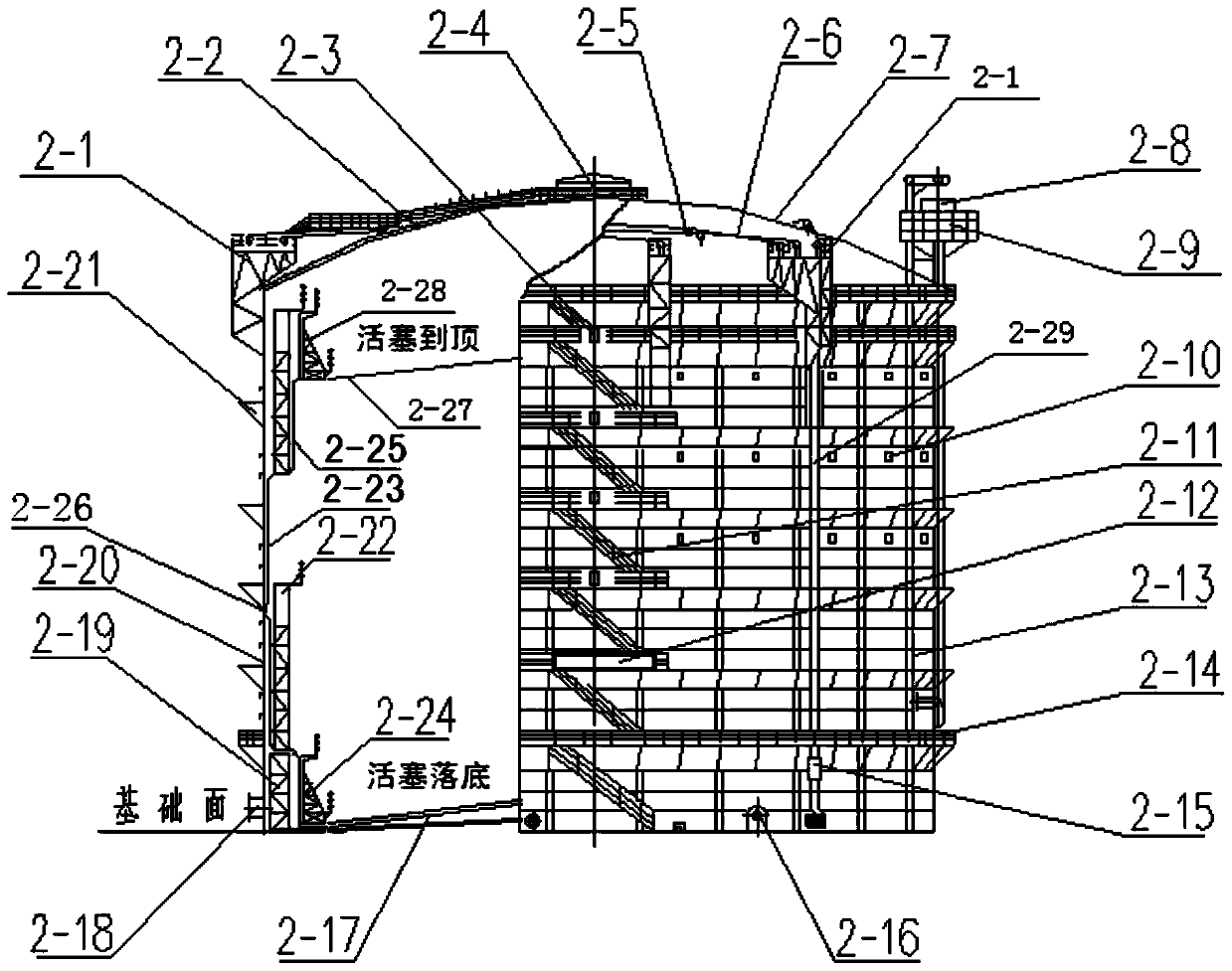

[0054] like figure 2 As shown, the conventional double-stage rubber membrane sealed dry gas tank includes a leveling device (mainly composed of a leveling bracket 2-1, a leveling counterweight 2-15, and a leveling counterweight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com