Light-scattering-method-based PM2.5 monitor calibration method and device

A technology of light scattering method and calibration method, which is applied in the field of testing, can solve problems such as low calibration efficiency, complicated calibration process of PM2.5 monitors, and difficulty in traceability to quality standards, so as to save testing costs, fast measurement speed, and simple structure reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

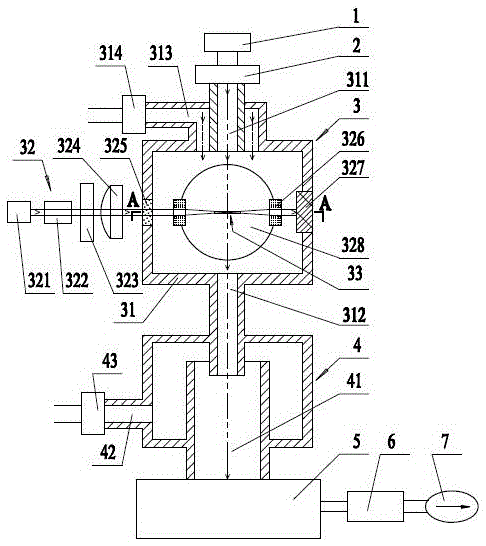

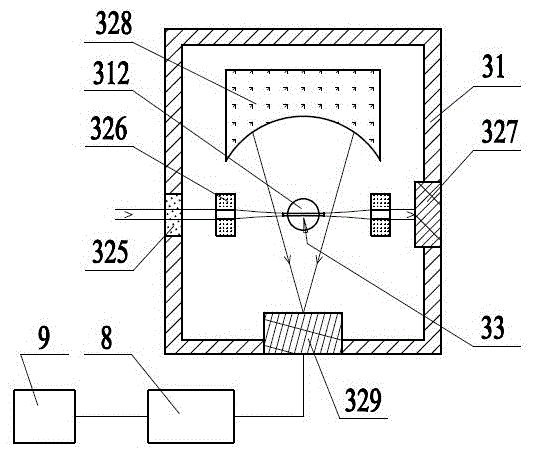

[0020] Such as figure 1 and 2 As shown, a PM2.5 monitor calibration device based on the light scattering method, which includes a monodisperse aerosol generator 1 , a detection module 3 , and a mixing chamber 4 connected in sequence. figure 1 The up and down direction is the Y-axis direction; the left-right direction is the X-axis direction; figure 2 The upper and lower directions are the Z-axis direction, the upper part is the rear, and the lower part is the front. In the figure: the double dotted line with arrows indicates the air flow; the thin solid line with the right arrow indicates the optical path. The detection module 3 includes: an optical scattering cavity 31 and a light generating part 32 . The optical scattering cavity 31 is a sealed cavity structure. The optical scattering cavity 31 is provided with an augmenting lens 325 , a pair of second diaphragms 326 and an optical trap 327 arranged in a line along the X-axis direction. Both sides of the second apertur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com