Power line fault location device and method

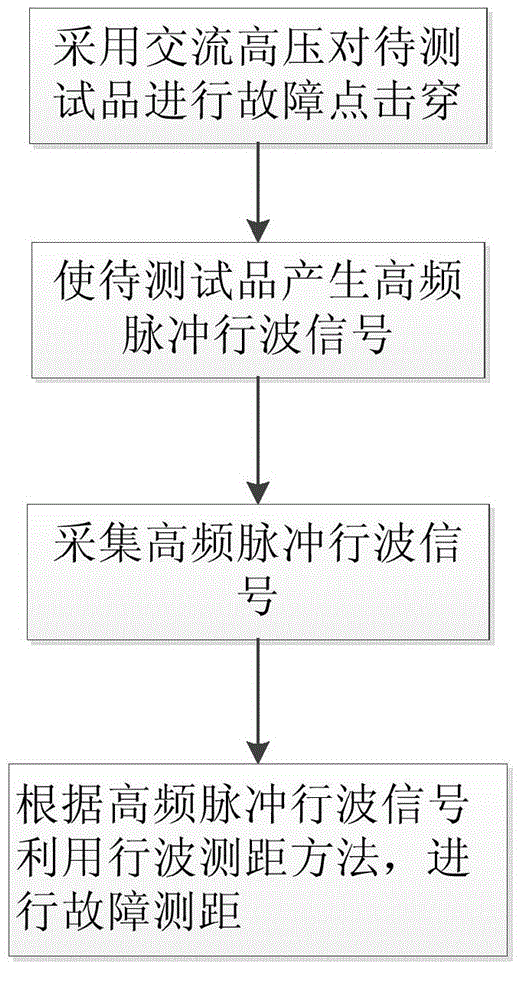

A technology of fault distance measurement and power line, which is applied to the fault location and uses the pulse reflection method to detect faults and other directions. It can solve the problems of poor DC pulse destructive power, increased fault point resistance, and unsatisfactory problems, and achieves a large fault point penetration capability. , to achieve the effect of integration and rapid ranging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

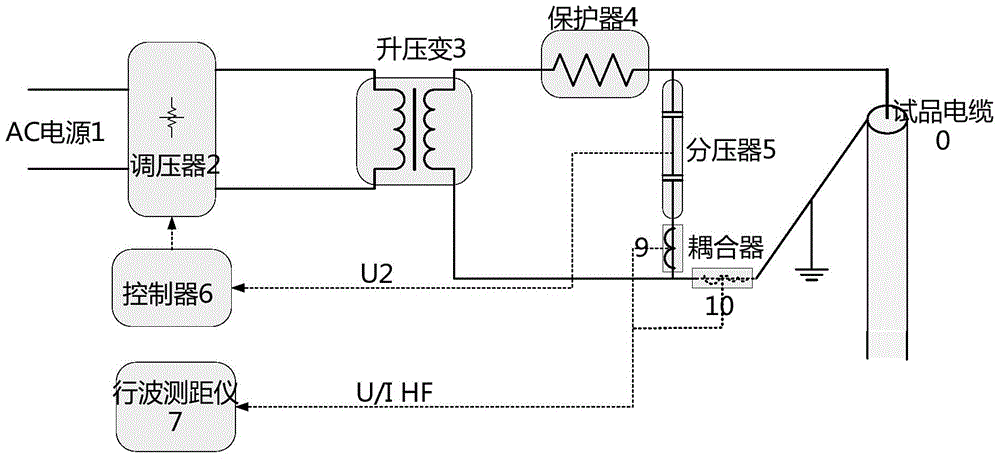

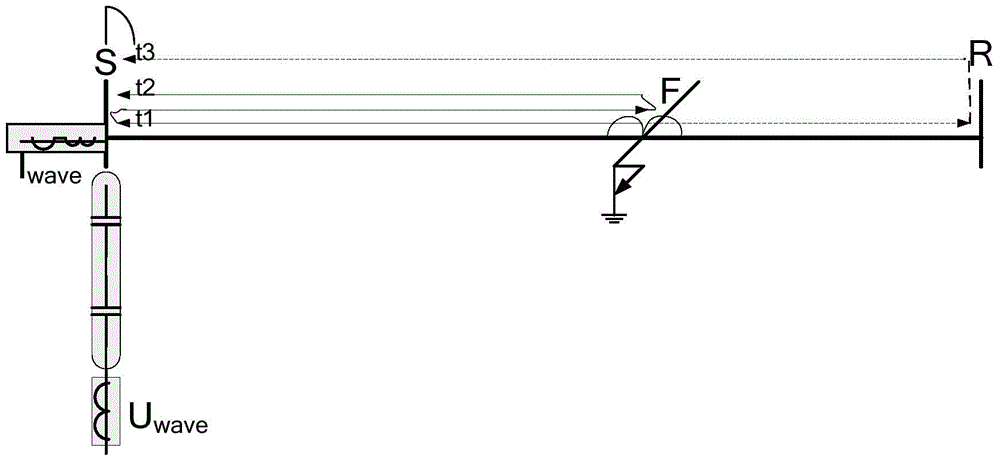

[0063] If you choose to process high-frequency AC voltage to the test product, you need to apply AC high voltage to the test product through a power frequency AC high-voltage device. figure 2 The structure and test wiring diagram of the power line fault location method are shown. refer to figure 2 , The system of the present invention includes an AC power supply 1 , a voltage regulator 2 , a step-up transformer 3 , a protector 4 , a voltage divider 5 , a controller 6 , a traveling wave range finder 7 , a voltage coupler 9 or a current coupler 10 . Wherein, the input end of the voltage regulator 2 is connected to the AC power source 1 , after voltage regulation, a part of the input voltage is taken as the output voltage, and the output voltage is input to the step-up transformer 3 . The step-up transformer 3 boosts the voltage of the input voltage, one end of the secondary side winding of the step-up transformer 3 is grounded, the other end is connected to the test object 0 ...

Embodiment 2

[0067] If you choose to process high-frequency AC voltage to the test product, you need to apply AC high voltage to the test product through a power frequency AC high-voltage device. Since the AC power needs to be boosted to the AC voltage, it will cause relatively large power loss. Therefore, the present invention improves Embodiment 1 by adopting power frequency series resonance technology. For the sake of simplicity, the following only focuses on two embodiments The differences are described in detail.

[0068] Such as Figure 5 As shown, a power frequency AC high voltage device is provided in this embodiment. The device includes: a voltage regulator 2, an excitation transformer 3, an adjustable inductance 11, a voltage divider 5, a controller 6, a traveling wave rangefinder 7, a coupling The input end of the voltage regulator 2 is connected to the AC power source 1, and the output voltage is input to the excitation transformer 3 after voltage regulation; one end of the se...

Embodiment 3

[0071] If you choose to add frequency conversion series resonant high voltage to the test product, you need to add AC high voltage to the test product through the frequency conversion series resonant high voltage device. Since the AC power needs to be boosted to the AC voltage, it will cause a relatively large power loss. Therefore, the present invention improves Embodiment 1 by adopting frequency conversion series resonance technology. For the sake of simplicity, the following only focuses on the two embodiments. The differences are described in detail.

[0072] Such as Figure 8 As shown, a frequency conversion series resonant high-voltage device is provided in this embodiment, and the device includes: a frequency converter 2, an excitation transformer 3, an inductor 4, a voltage divider 6, a controller 7, a traveling wave range finder 7, and a coupler; The input end of the frequency converter 2 is connected to the industrial frequency power supply 1, the output end is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com