Inspection method for scribe groove structure design in mask design

A technology of structural design and inspection method, which is applied in calculation, instrumentation, electrical digital data processing, etc., can solve the problems of photolithographic alignment test pattern leakage, failure to ensure correctness, and time-consuming, etc., to shorten the inspection time , easy to batch process, and reduce the effect of error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

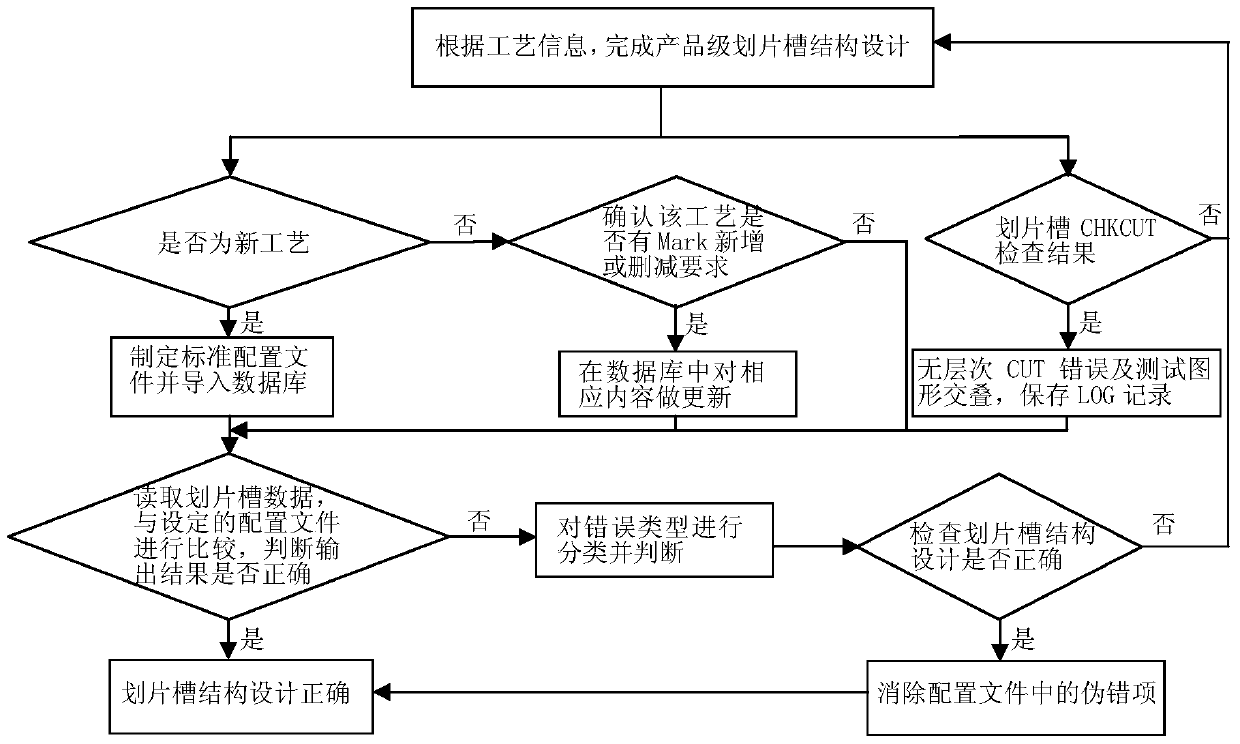

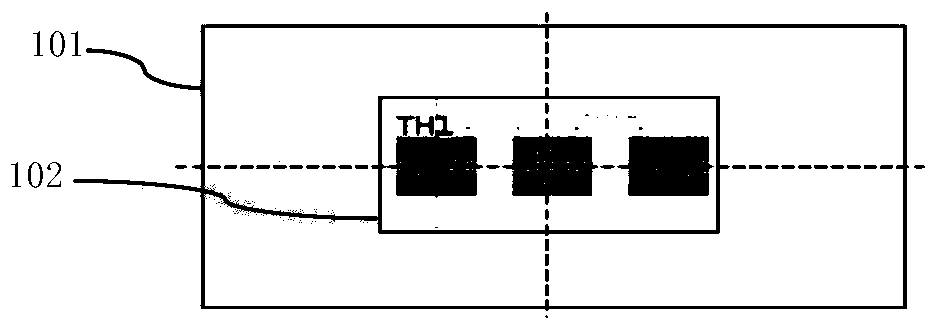

[0032] Such as figure 1 As shown, it is a flow chart of the method of the embodiment of the present invention; the inspection method of the design of the scribe groove structure in the mask plate design of the embodiment of the present invention includes the following steps:

[0033] Step 1. Develop a corresponding standard configuration file for each process, and the standard configuration file is provided with information of all alignment marks or test patterns of the scribing grooves of the corresponding process. Developing the corresponding standard configuration file for each process includes the following steps:

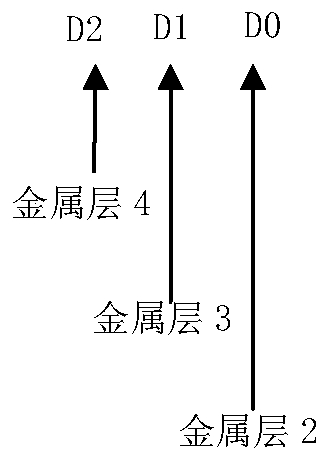

[0034] Step 11, determining the minimum and maximum number of metal layers supported by the corresponding process. For example, the corresponding process name is CZ6H, the lowest is 2 layers of aluminum, and the highest is 4 layers of aluminum.

[0035] Step 12. Determine how many optional levels, that is, option marks, the corresponding process contains. Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com